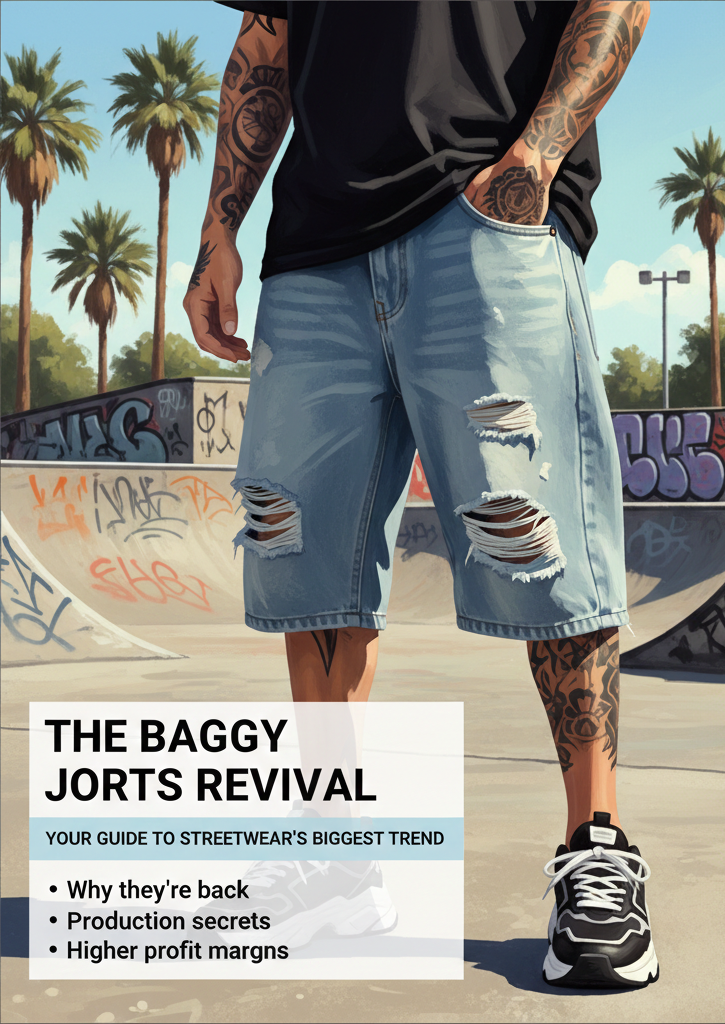

If you’ve looked at any streetwear lookbook lately, you’ve seen it: massive, oversized denim shorts that hit well below the knee. These aren’t just “shorts”—the market calls them baggy jorts, and they are currently a massive revenue driver for independent labels.

For a brand, this isn’t just about following a trend. It’s about a product that is technically easier to produce than full jeans but carries the same “premium” price tag.

Here is the reality of why baggy jorts are dominating and how to get the production right without wasting your budget.

Why Are Baggy Jorts Suddenly Everywhere Again?

Fashion moves in cycles, and we are currently deep in a 90s/Y2K obsession. But it’s more than just nostalgia:

- The Comfort Factor: After a decade of tight denim, people want to move. Baggy jorts provide a relaxed silhouette that fits the “effortless” look Gen-Z and Millennials are buying.

- The “Instagram” Silhouette: Big, boxy shapes photograph better than slim ones. They create a distinct “look” that helps a brand stand out on a crowded social media feed.

- The Skate & Hip-Hop Connection: This style has deep roots in authentic street culture. Brands that produce baggy jorts are tapping into a “real” aesthetic that consumers trust.

What Makes a Pair of Jorts “Premium” Instead of Cheap?

You can’t just cut the legs off a pair of old jeans and call it a day. Modern, high-end jorts have specific technical specs:

- The Inseam: They need to hit at the knee or slightly below. Too short, and they lose the streetwear “edge.”

- The Fabric Weight: Use 11oz to 13oz rigid denim. If the fabric is too light, it won’t hold that wide, boxy shape and will just look floppy.

- The Details: Think “Carpenter” style. Hammer loops, extra tool pockets, and heavy-duty contrast stitching are what people are paying for right now.

- The Leg Opening: It needs to be wide—often 12 inches or more—to create that specific oversized drape.

Why Are Jorts Less Risky to Produce Than Full Jeans?

If you are a new brand, starting with denim is terrifying because of the costs. Baggy jorts are a much safer entry point for a few reasons:

- Lower Fabric Usage: You use significantly less yardage than full-length jeans, which keeps your raw material costs down.

- Forgiving Fit: A “baggy” fit is much easier to get right than a “slim” fit. You’ll deal with far fewer customer returns because the sizing doesn’t need to be pinpoint accurate to look good.

- Faster Turnaround: Less sewing time in the factory means you can get your product to market faster.

How Do You Get the Pattern and Proportions Right?

This is where most brands fail. A baggy jort shouldn’t look like a tent or a diaper.

- Pattern Balance: The waist needs to fit true to size, while the thigh and leg opening scale up.

- The Wash: This is the most expensive part of the process. For baggy styles, a heavy stone wash or acid wash usually looks best. It softens the heavy fabric so it hangs correctly.

- Sampling is Non-Negotiable: You must see how the fabric reacts to the wash. Denim shrinks. If your pattern doesn’t account for 3-5% shrinkage after a heavy vintage wash, your “baggy” shorts will arrive looking like “regular” shorts.

Where is the Real Profit Potential?

Here is the industry secret: You can often sell a pair of high-quality, custom-washed baggy jorts for nearly the same price as full jeans, even though they cost you 20-30% less to manufacture.

Streetwear customers aren’t paying for the amount of fabric; they are paying for the silhouette and the wash. If your branding is on point—think leather back-patches and custom-engraved buttons—your margins on jorts will likely be the highest in your entire summer collection.

Why Do So Many Startups Launch with Jorts First?

Developing a full line of jeans requires a massive investment in sizing and inventory. Jorts allow you to:

- Test your denim supplier’s quality.

- See if your audience likes your “wash” aesthetic.

- Build up the cash flow needed to fund a full denim pant line later in the year.

How Do You Find the Right Manufacturer for This?

Don’t go to a factory that specializes in t-shirts or hoodies. Denim manufacturing is a completely different world. You need a partner who:

- Specializes in Heavyweight Denim: They need the right needles and machines to handle 13oz fabric.

- Has an In-House Wash Lab: So they can tweak the fading and whiskering to match your vision.

- Understand Streetwear Proportions: You want a factory that has made “baggy” styles before, so they don’t try to “fix” your pattern into a more traditional (boring) fit.

Frequently Asked Questions (FAQ)

What is the best fabric weight for baggy jorts?

Stick to 12oz or 13oz. Anything lighter feels like “fast fashion” and won’t hang right. Anything heavier than 14oz might be too stiff and uncomfortable for summer wear.

Should I go with 100% cotton or a stretch blend?

For the authentic baggy streetwear look, 100% cotton (rigid denim) is the only way to go. Stretch denim is for comfort-focused “dad” shorts; it doesn’t have the structural integrity needed for an oversized silhouette.

How do I handle the “raw hem” look?

If you want the distressed, frayed bottom, tell your factory to do a “raw hem with a stay-stitch.” This allows the edge to fray for the aesthetic, but the stay-stitch prevents the shorts from unraveling completely after five washes.

What’s the minimum order (MOQ) I should expect for custom washes?

Most specialized denim factories will want at least 100-200 pieces per wash. This is because the industrial washing machines are huge; running a “small” batch of 50 pieces is inefficient and will double your unit cost.