How Denim Weight Impacts Fit, Comfort, Washing, and Production Decisions

When brands talk about denim weight, it’s often reduced to a single number — 10 oz, 12 oz, 14 oz.

In real production, denim weight affects far more than how “thick” a fabric feels.

From a factory perspective, denim weight influences pattern behavior, wash results, sewing difficulty, wear comfort, and even return rates after bulk delivery. Many sourcing issues that appear later in production can be traced back to an early misunderstanding of denim weight.

This guide breaks down denim weights in practical terms, based on how they behave during sampling, washing, and bulk manufacturing — not how they are described in trend reports.

What Does “Denim Weight” Actually Mean?

Denim weight is measured in ounces per square yard (oz/yd²).

It describes how much one square yard of fabric weighs before washing.

However, two fabrics with the same stated weight can still behave very differently due to:

- Yarn type and density

- Weave tightness

- Fiber composition (cotton, blends, stretch)

- Finishing and sanforization level

This is why factories rarely judge denim only by the oz number — weight is a reference point, not a performance guarantee.

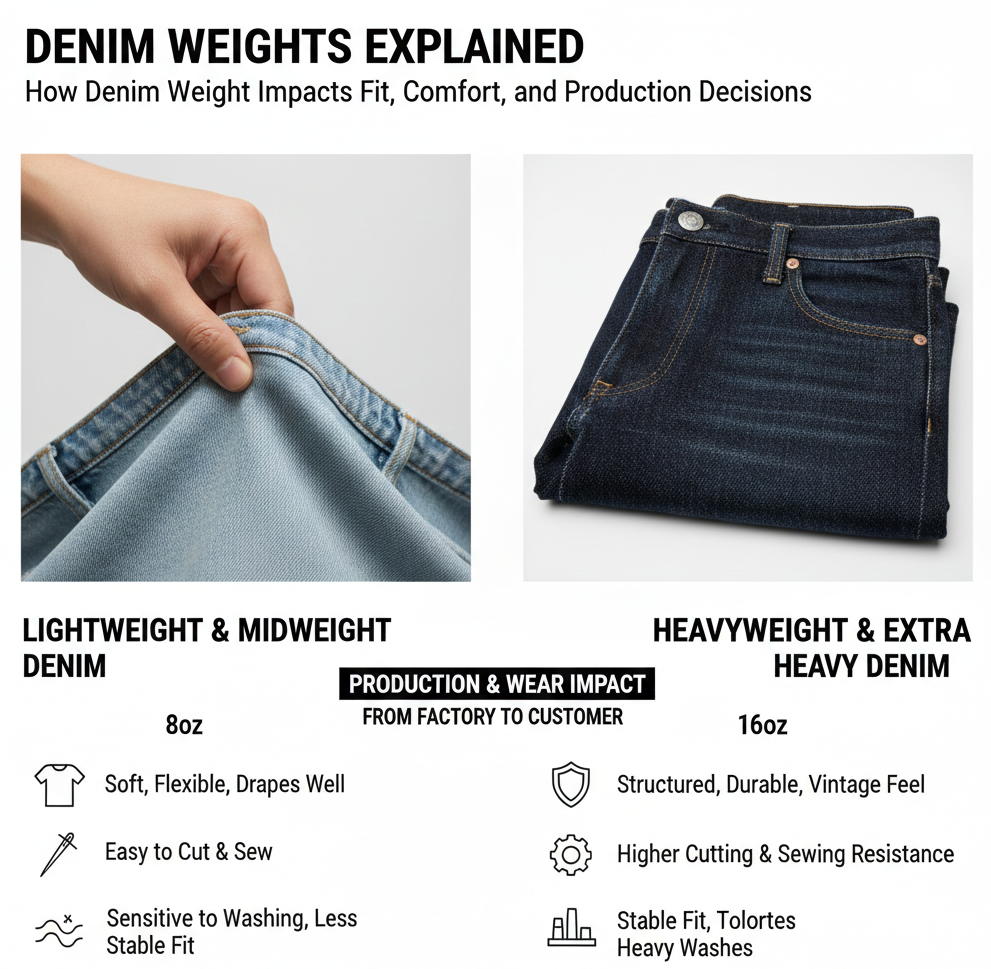

Common Denim Weight Categories (Factory Classification)

| Denim Weight | Typical Range | Factory Description |

|---|---|---|

| Lightweight | 6–9 oz | Soft, flexible, easy to sew |

| Midweight | 10–12 oz | Balanced, most commercial jeans |

| Heavyweight | 13–15 oz | Structured, durable |

| Extra Heavy | 16 oz+ | Rigid, niche, heritage-focused |

This classification is more useful in production than marketing labels like “summer denim” or “premium heavy denim.”

Lightweight Denim (6–9 oz)

Lightweight denim is often chosen by brands prioritizing comfort, drape, and warm-weather wear.

How It Behaves in Production

- Easier to cut and sew

- Lower needle resistance

- More sensitive to distortion during washing

- Requires tighter pattern tolerance

Typical Use Cases

- Women’s relaxed jeans

- Shirts, lightweight denim jackets

- Fashion-driven silhouettes

- Warm-climate markets

Common Factory Observations

Lightweight denim tends to exaggerate fit issues.

If pattern balance is off, the fabric will not “hide” mistakes.

From a production standpoint, lightweight denim works best when the brand already has a clear fit standard and controlled washing processes.

Midweight Denim (10–12 oz)

This is the most widely used denim weight in commercial production.

Why Factories Prefer It

- Stable during washing

- Predictable shrinkage

- Balanced comfort and durability

- Compatible with most wash programs

Typical Use Cases

- Core men’s and women’s jeans

- Private label programs

- DTC brands scaling production

- First-time collections

Production Reality

For new brands, midweight denim often delivers the lowest overall risk.

It allows room for design flexibility without causing major surprises during bulk production.

Many factories recommend starting here unless the brand has a clear reason not to.

Heavyweight Denim (13–15 oz)

Heavyweight denim is associated with durability, structure, and long wear.

How It Affects Manufacturing

- Higher cutting resistance

- Increased sewing wear on needles

- Requires stronger seams and reinforcement

- Wash effects appear more gradually

Typical Use Cases

- Men’s classic jeans

- Workwear-inspired styles

- Straight and wide-leg fits

- Brands emphasizing longevity

Important Consideration

Heavier denim does not automatically mean “better quality.”

If the pattern and wash are poorly engineered, heavy denim can feel restrictive and uncomfortable, especially for first-time customers.

Extra Heavy Denim (16 oz and Above)

This category is far less common in mass production.

Factory Perspective

- Slower production speed

- Higher defect risk during sewing

- Limited wash flexibility

- Higher unit cost

Typical Use Cases

- Heritage and archival reproductions

- Selvedge-focused brands

- Small-batch or enthusiast markets

Extra heavy denim works best when the brand fully understands its customer and is prepared for longer break-in periods.

How Denim Weight Impacts Fit Stability

Denim weight directly affects how a garment holds its shape over time.

| Weight Category | Fit Stability After Wash | Pattern Sensitivity |

|---|---|---|

| Lightweight | Low–Medium | High |

| Midweight | Medium–High | Medium |

| Heavyweight | High | Low–Medium |

| Extra Heavy | Very High | Low |

This is one reason many factories caution against using very light denim for complex or tight silhouettes.

Denim Weight and Washing Results

Weight changes how denim reacts to washing, not just visually but structurally.

General Patterns Observed in Production

- Lighter denim shows wash effects faster but risks over-processing

- Heavier denim requires stronger wash programs to show contrast

- Aggressive washes on light denim can weaken seams

- Heavy denim tolerates distressing better

This is why fabric selection should always happen before finalizing wash recipes.

Cost and MOQ Considerations by Weight

| Weight | Fabric Cost Trend | MOQ Flexibility |

|---|---|---|

| Lightweight | Lower | High |

| Midweight | Medium | High |

| Heavyweight | Medium–High | Medium |

| Extra Heavy | High | Low |

Heavier fabrics often require more controlled sourcing, which can increase MOQs or limit substitution options during bulk production.

Common Sourcing Mistakes Related to Denim Weight

From factory experience, these issues appear frequently:

- Choosing weight based on trend photos instead of wear context

- Assuming heavier denim solves fit problems

- Ignoring how weight interacts with stretch or fiber blends

- Changing weight after sampling without pattern adjustment

In many failed productions, denim weight was not “wrong” — it was simply mismatched to the product goal.

How to Choose the Right Denim Weight (Practical Framework)

Before confirming fabric, brands should ask:

- Will the customer wear this daily or occasionally?

- Does the silhouette require flexibility or structure?

- How aggressive is the wash program?

- Is this a first collection or a repeat style?

If uncertainty remains, factories often suggest developing two weights during sampling to compare real-world performance.

Final Manufacturing Insight

Denim weight is not about being light or heavy — it’s about control.

The most successful brands choose denim weight based on how the garment behaves after washing, wearing, and repeated production runs, not how it sounds in a product description.

Understanding weight early reduces sampling revisions, bulk risk, and post-sale complaints.

Related Guides

- Stretch vs Non-Stretch Denim: How Fabric Choice Impacts Fit

- Choosing the Right Denim Fabric for Your First Jeans Collection

- Denim Washing Effects on Fit and Fabric Performance

- MOQ Strategy for Custom Denim Manufacturing