Fit & Pattern Making in Jeans Manufacturing

In denim manufacturing, fit is not a finishing step. It is the structure that everything else depends on.

Fabric, wash, and construction all matter, but when fit is wrong, none of them can save the product. Most returns, reworks, and delayed bulk approvals trace back to early decisions made during pattern development.

This Guide brings together how fit is developed, adjusted, and controlled in real jeans production — from first patterns to bulk consistency.

Why fit development matters more than many brands expect

Many brands focus on how jeans look on a model or mannequin. Factories focus on how the jeans behave across sizes, after washing, and during wear.

A fit that looks correct in one sample size can fail quickly when scaled to full size ranges. This is especially true in women’s and plus size denim.

From a production standpoint, fit affects:

- Sampling cycles

- Fabric selection

- Grading stability

- Return and exchange rates

That is why fit work starts earlier than most people expect.

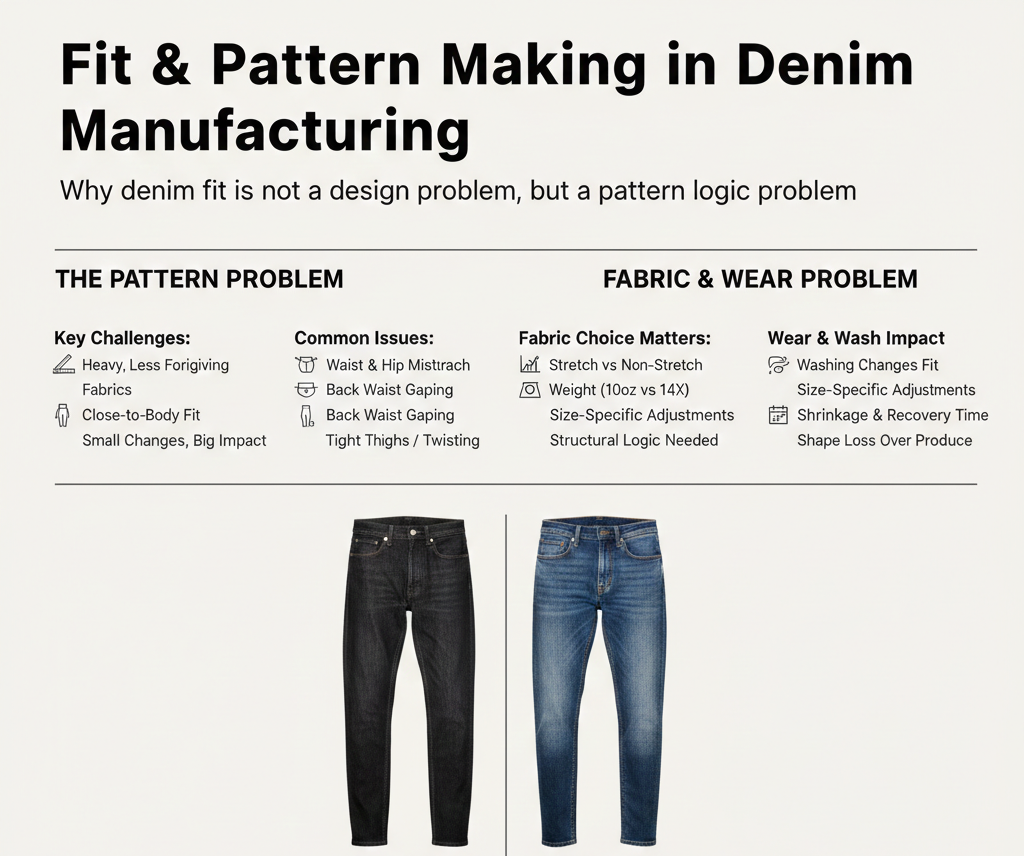

How jeans patterns are developed in manufacturing

A jeans pattern is not just a shape. It is a balance system.

Factories build patterns by considering:

- Body proportions

- Fabric stretch and weight

- Intended wash process

- Target customer movement

Early pattern decisions set limits on what later adjustments can fix. A strong base pattern reduces the need for repeated corrections during sampling.

👉 Related page: Jeans Pattern Development Process

Why fit adjustment is not trial-and-error

Fit revisions often look simple from the outside — tighten here, loosen there. In reality, every change shifts tension across the garment.

When factories adjust fit, they track:

- Which seam carries stress

- How ease redistributes during wear

- Whether fabric recovery supports the change

Random adjustments often solve one problem while creating another. Controlled revision is what separates stable production fits from unstable ones.

👉 Related page: Fit Adjustment & Revision Workflow

How fabric choice affects fit outcomes

Fit cannot be separated from fabric.

Stretch, recovery, and fabric weight all influence how a pattern performs. A pattern developed in non-stretch denim will behave very differently when switched to stretch — even at low elastane percentages.

This is why factories test fit together with fabric, not after.

👉 Related page: How Stretch Denim Affects Fit

Why plus size fit requires a different logic

Plus size denim magnifies every fit issue.

Waist gaping, thigh restriction, and seat sagging often come from patterns that were simply scaled up from straight sizes. Fabric stretch alone cannot compensate for incorrect structure.

Factories approach plus size fit as a separate system, not an extension.

👉 Related page: Plus Size Denim Pattern Logic

Men’s vs women’s fit: why one approach does not work

Men’s and women’s jeans are built on different assumptions about body movement and proportions.

Men’s fits rely more on structure and balance. Women’s fits rely more on controlled ease and fabric behavior. Using the same logic for both increases revision risk.

👉 Related page: Men’s vs Women’s Fit Differences

Fit consistency from sample to bulk

A common problem brands face is approving a fit sample that does not repeat in bulk.

This usually happens when:

- Fabric batches vary

- Stretch recovery is not tested

- Grading rules are unstable

Factories monitor fit consistency through measurement checkpoints and wear testing, not visuals alone.

👉 Related page: Measurement & Fit Consistency

How this hub is meant to be used

This section is not about trends or styling. It is built to help brands make fit decisions that survive production.

Whether you are launching your first jeans or refining an existing line, understanding how patterns and fit work together reduces cost, time, and risk.