A Practical Guide to Fit, Shrinkage, Stretch & Production Consistency

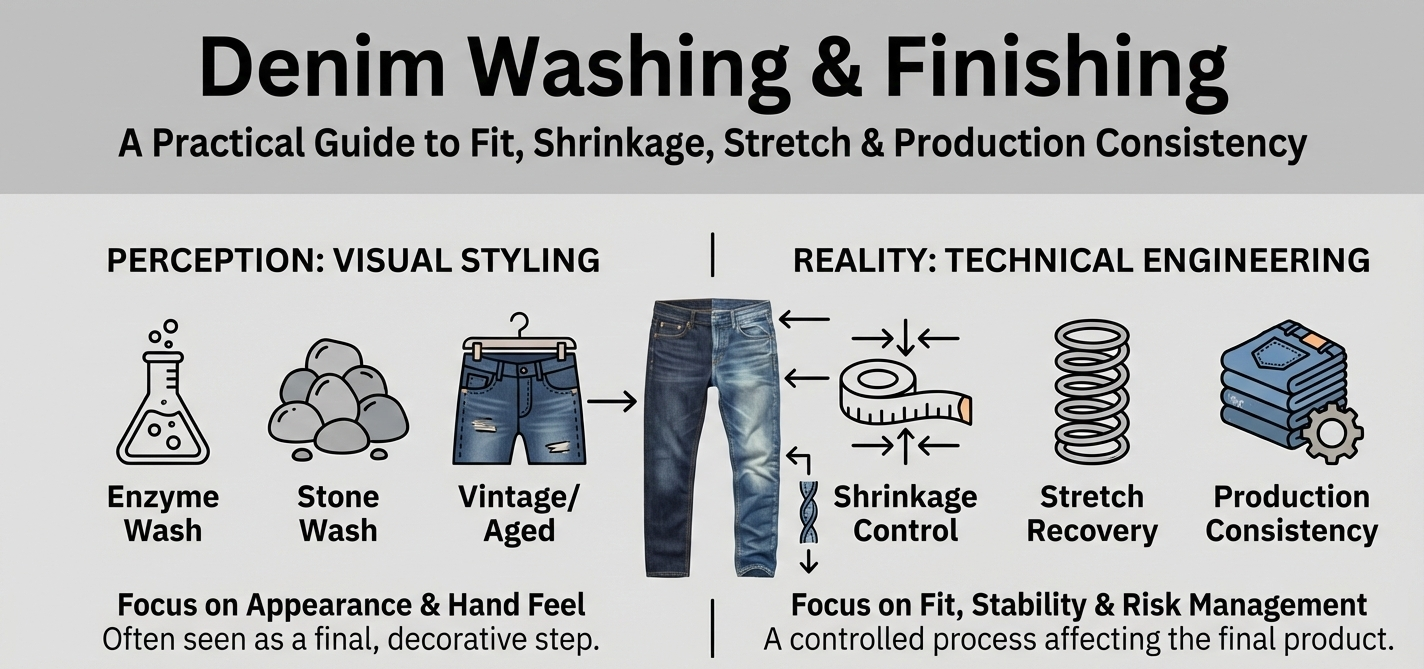

Denim washing and finishing are often described as “the last step” in jeans production, but in reality, they influence the final product more than many brands expect.

Fit, hand feel, shrinkage, stretch recovery, color stability, and even defect rates are closely tied to how denim is washed and finished.

For brands working with bulk production — especially stretch denim, vintage styles, or plus-size fits — washing is not a styling detail. It is a technical process that affects consistency and risk.

This hub page explains how denim washing and finishing work in practice, what decisions matter most, and how washing choices connect directly to fit and production outcomes.

What Is Denim Washing & Finishing?

In simple terms:

- Washing refers to wet processes that change the fabric’s appearance, softness, and size behavior

- Finishing includes both wet and dry processes used to stabilize, soften, or enhance the garment after washing

These steps usually happen after sewing, which means any change caused by washing happens to a fully constructed garment — not flat fabric.

That is why washing decisions must be aligned with:

- pattern making

- fabric selection

- fit expectations

- target shrinkage tolerance

Why Washing Matters More Than Most Brands Expect

Many production issues that appear “after delivery” actually start during washing.

Common outcomes influenced by washing include:

- waist and hip measurement changes

- leg twist or seam torque

- uneven shrinkage between panels

- loss of stretch recovery

- unexpected stiffness or over-softness

Once washing is complete, most of these changes cannot be corrected without rework or rejection.

This is why experienced denim factories treat washing as a controlled production step, not a visual add-on.

How Washing Interacts with Fabric Type

Different denim fabrics react very differently in washing.

For example:

- 100% cotton denim is more predictable but more prone to shrinkage

- Stretch denim is sensitive to temperature, time, and mechanical action

- Rigid denim with vintage effects often shows higher size variance

- Heavier oz denim resists change but increases risk of uneven results

Understanding fabric behavior before washing is critical — especially for brands planning repeated reorders.

👉 This topic is explained in detail here:

Stretch Denim Washing Risks and Control Points

Washing Methods Are Not Just Visual Choices

Many brands select washing methods based on reference photos.

In production, however, each method carries technical trade-offs.

Common washing methods include:

- rinse wash

- enzyme wash

- stone wash

- vintage / aged wash

- clean or raw-style wash

Each method affects:

- surface texture

- fiber damage level

- size stability

- batch-to-batch consistency

Two washes that look similar in photos may behave very differently in bulk.

👉 For a clear comparison, see:

Vintage Wash vs Clean Wash in Denim Production

How Washing Directly Changes Fit

One of the most misunderstood aspects of denim washing is its impact on fit.

Washing can:

- reduce waist and hip measurements

- change rise perception

- tighten thigh and knee areas

- alter leg opening width

- affect stretch rebound after wear

These changes do not happen evenly across the garment.

Panels with:

- different grain directions

- varying fabric tension

- elastic yarn content

will react differently during washing and drying.

That is why fit approval before washing does not guarantee fit accuracy after washing.

👉 A full breakdown is covered here:

How Washing Changes Fit in Denim Garments

Washing Risk Increases in Bulk Production

In sampling, washing results often look stable because:

- quantities are small

- machines are lightly loaded

- operators give extra attention

In bulk production:

- load size increases

- time pressure is higher

- small variations multiply

This is where many brands experience:

- size inconsistency

- shade variation

- rejected lots

- delayed shipments

Proper wash testing, shrinkage allowance, and tolerance planning help reduce these risks.

Washing & Pattern Making Must Work Together

Washing decisions should not be separated from pattern logic.

Key coordination points include:

- shrinkage allowance in patterns

- stretch recovery targets

- grading strategy for different sizes

- expected post-wash measurements

This is especially important for:

- plus-size denim

- high-stretch styles

- slim or fitted silhouettes

When washing and pattern teams work in isolation, fit issues usually appear too late.

This Hub and Related Washing Pages

This page serves as the central reference for our denim washing and finishing knowledge.

Detailed topics are covered in the following pages:

- Denim Washing Methods Explained

A practical overview of common washing processes and their real production impact. - Stretch Denim Washing Risks

Why stretch fabrics are more sensitive and how washing affects recovery and fit. - Vintage Wash vs Clean Wash

A comparison of two popular wash directions and their technical differences. - How Washing Changes Fit

A focused look at how washing alters garment measurements and wear feel.

Each article goes deeper into one aspect, while this hub connects them into a complete production view.

Who This Guide Is For

This washing and finishing guide is written for:

- denim brands developing new styles

- designers working on fit-sensitive products

- sourcing teams managing bulk production

- buyers comparing factories or wash capabilities

The goal is not to promote a specific wash, but to help brands make informed decisions before production begins.

Final Thoughts

Denim washing and finishing shape the final product more than most people realize.

Understanding how washing affects fit, stretch, and consistency helps brands reduce risk, control quality, and avoid costly surprises.

A well-planned washing process is not about complexity — it is about alignment between fabric, pattern, and production reality.