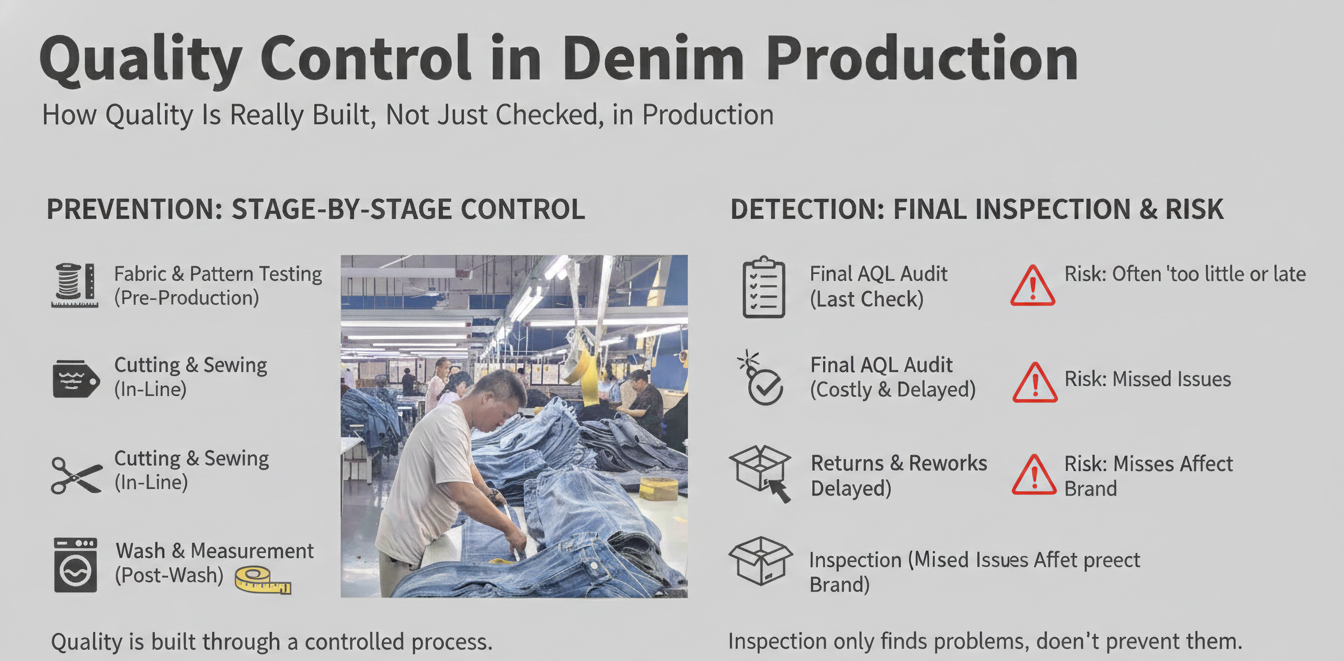

Quality control in denim production is often discussed, but rarely explained in a way that reflects what actually happens on a factory floor. Many brands only notice quality issues after bulk goods arrive, when fixing them is expensive or no longer possible.

In reality, denim quality is not controlled at one single checkpoint. It is built step by step, from fabric selection to final packing. Each stage has its own risks, and most production problems come from small details being overlooked early on.

This page explains how quality control works in real denim manufacturing, where problems usually start, and how experienced factories reduce risk before bulk production moves too far.

Why is quality control more than just final inspection in denim manufacturing?

Many buyers assume quality control means checking finished jeans before shipment. That step is important, but it is also the last line of defense.

By the time finished inspection begins, most quality issues are already locked in. Fabric shrinkage, pattern tolerance, wash variation, and sewing imbalance cannot be fully corrected at the end.

Effective denim quality control starts much earlier. It focuses on preventing issues instead of detecting them late. This is especially important for stretch denim, washed styles, and multi-size runs.

Factories that rely only on final inspection usually face higher rework rates, delayed shipments, and disputes with brands.

Where do most denim quality problems actually start?

From production experience, quality problems in jeans usually begin in four areas:

- Fabric behavior not fully tested before bulk

- Pattern tolerance not aligned with bulk cutting

- Wash results changing at scale

- Inconsistent sewing standards across production lines

These issues rarely come from poor workmanship alone. They often come from missing communication between development, production, and quality teams.

Quality control is not just about checking defects. It is about controlling variables.

How is fabric quality controlled before bulk production?

Fabric is the foundation of denim quality. Once bulk cutting starts, fabric-related issues become very hard to fix.

Before bulk production, professional factories usually focus on:

- Fabric weight consistency

- Stretch and recovery performance

- Shrinkage after washing

- Color stability and shade range

For stretch denim, testing stretch percentage alone is not enough. Recovery behavior after wash and wear matters just as much. A fabric that stretches well but does not recover will lead to bagging, knee growth, and fit complaints.

Shrinkage testing is also critical. Denim often shrinks differently in length and width, and washed styles amplify this effect. If shrinkage data is not properly applied to patterns, final measurements will drift.

Fabric approval should never be visual only. Data matters more than appearance at this stage.

How does pattern control affect denim quality?

Patterns translate design intent into physical garments. Even small pattern errors can create large quality issues at scale.

Key pattern-related risks include:

- Inconsistent grading across sizes

- Incorrect shrinkage allowance

- Stretch fabric not compensated properly

- Wash effects not reflected in pattern dimensions

For example, a pattern that works well for size M may not scale properly into plus sizes or extended ranges. This often results in tight thighs, rising waistlines, or imbalance between front and back rise.

Quality control at the pattern stage means reviewing measurements, grading logic, and how fabric behavior affects fit after wash.

Once cutting begins, pattern issues become production issues.

What role does cutting play in denim quality control?

Cutting is one of the most underestimated stages in denim production.

Even with approved fabric and patterns, poor cutting control can cause:

- Size inconsistency

- Twisting or leg imbalance

- Excessive tolerance variation

Professional factories control cutting by:

- Layer height limits for stretch denim

- Marker efficiency balanced with accuracy

- Directional cutting for denim grain

- Frequent measurement checks during cutting

Stretch denim, in particular, requires tighter cutting control. Too many layers or excessive pressure can stretch fabric before sewing even begins.

Cutting accuracy sets the baseline for everything that follows.

How is sewing quality controlled during bulk production?

Sewing quality is not only about clean stitches. It is about consistency.

In denim production, sewing control usually focuses on:

- Stitch density and tension

- Seam alignment and balance

- Reinforcement at stress points

- Operator consistency across lines

Different operators sew differently. Without clear standards, two production lines can produce noticeably different results.

Experienced factories reduce this risk by:

- Using approved sewing samples as physical standards

- Setting clear machine parameters

- Conducting in-line quality checks, not just end-line checks

For stretch denim, seam elasticity and stitch breakage risk are also evaluated. A seam that looks fine on the table may fail during wear if stretch behavior is not considered.

Why is washing the biggest quality risk in denim production?

Washing is where many denim quality issues become visible for the first time.

Common wash-related problems include:

- Unexpected shrinkage

- Shade inconsistency

- Fit distortion after wash

- Damage to stretch recovery

A wash recipe that works on one batch may behave differently at scale. Drum load, water ratio, enzyme strength, and drying temperature all affect results.

This is why wash testing before bulk is critical. Factories usually run multiple wash tests to observe:

- Measurement changes

- Color variance across pieces

- Fabric hand feel after wash

- Stretch performance after drying

Quality control during washing is not about chasing a perfect look. It is about repeatability.

How are measurements controlled during and after washing?

Measurement control in denim production is ongoing.

Factories usually measure:

- Pre-wash garments

- Post-wash garments

- Random samples during bulk runs

The goal is not zero deviation. Denim naturally allows tolerance. The goal is keeping variation within an agreed range.

Clear tolerance standards should be set before production starts. Without this, disagreements often happen after delivery.

Measurement control is especially important for:

- Slim and fitted styles

- Stretch denim

- Plus size ranges

Ignoring measurement tracking during bulk often leads to inconsistent sizing and returns.

What is in-line quality control and why does it matter?

In-line quality control happens during production, not after it.

This includes:

- Spot checks during sewing

- Measurement verification mid-production

- Visual inspection after key operations

In-line control allows factories to correct issues before hundreds of units are affected.

Factories that skip in-line checks often rely on final inspection to catch problems. At that point, corrections are slow and costly.

Strong quality systems focus on early detection.

How does final inspection fit into the quality control process?

Final inspection is still necessary, but it should confirm quality, not discover problems.

At this stage, inspectors typically check:

- Appearance and finishing

- Measurement compliance

- Functionality of trims and closures

- Packaging accuracy

If major issues are found during final inspection, it usually indicates earlier control failures.

Final inspection should be a verification step, not a rescue operation.

How do factories balance quality control and production efficiency?

Quality control does not mean slowing production to a stop.

Well-managed factories balance quality and efficiency by:

- Setting realistic tolerances

- Training operators clearly

- Standardizing processes

- Using data instead of assumptions

Over-control can cause delays, while under-control causes rework. The balance comes from experience and clear communication with brands.

Quality expectations should be aligned early, not negotiated after production starts.

Why do brands and factories often disagree on quality issues?

Most quality disputes come from misaligned expectations, not bad intent.

Common reasons include:

- Unclear tolerance standards

- Visual expectations not documented

- Wash variation not discussed early

- Fit expectations based only on samples

Clear documentation, pre-production samples, and realistic discussions reduce conflict significantly.

Quality control works best when both sides understand the limits of denim.

What should brands look for in a factory’s quality control system?

When evaluating a denim factory, brands should ask:

- How fabric is tested before bulk

- How wash results are controlled

- How measurements are tracked during production

- How in-line inspections are done

Strong factories explain their process clearly. Weak factories rely on promises.

Quality control is not a slogan. It is a system.

Why quality control is a long-term partnership issue

Denim quality improves over time when factories and brands work together consistently.

Each production run builds data. Fit adjustments become more accurate. Wash behavior becomes more predictable.

Factories that treat quality control as a shared responsibility usually deliver better results over multiple seasons.

Final thoughts on denim quality control

Quality control in denim production is not about perfection. It is about control, consistency, and understanding material limits.

Most serious quality issues can be avoided long before bulk production finishes. The key is knowing where to focus attention and how to manage risk realistically.