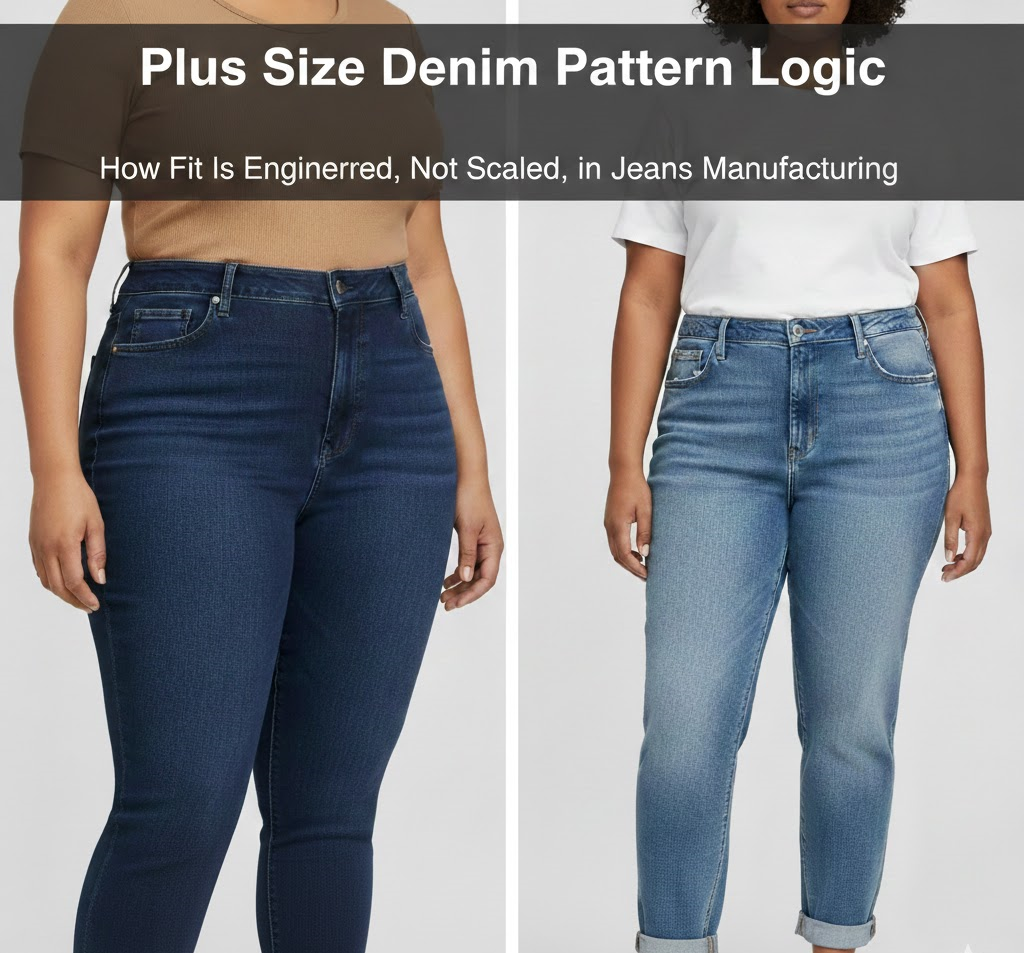

How Fit Is Engineered, Not Scaled, in Jeans Manufacturing

Plus size denim is often talked about as a sizing issue.

In real manufacturing, it is a pattern logic issue.

Many brands assume that plus size jeans are created by enlarging a standard pattern. That approach may work on paper, but it rarely works on the body. The result is familiar: jeans that fit the waist but pull at the thigh, hips that feel tight while the back waist gaps, or garments that look correct on a hanger but fail once worn.

From a factory point of view, plus size denim requires a different way of thinking about proportion, balance, and fabric behavior. It is not about making jeans bigger. It is about making them fit.

This Guide explains how plus size denim patterns are developed in real production, what usually goes wrong, and how fit risks are reduced before bulk manufacturing.

Why doesn’t standard grading work for plus size jeans?

Standard grading assumes that the body grows evenly as sizes increase. In reality, this is not how bodies change.

In plus size ranges, growth is not linear. The increase between waist, hip, thigh, and rise does not follow the same ratio used in core sizes. When a regular pattern is simply graded up, stress points appear quickly.

Common results include:

- Tight thighs with loose waists

- Excess fabric at the back rise

- Front rise pulling down during movement

- Seat drag lines and distorted pocket placement

From a pattern room perspective, these are not sewing problems. They are balance problems.

Plus size patterns require rethinking how volume is distributed, not just how much is added.

What makes plus size denim pattern logic different?

The main difference is where growth is added.

In core sizes, grading often focuses on width increases. In plus size, vertical balance becomes just as important. Rise depth, crotch shape, and hip curvature all change in ways that cannot be solved by simple increments.

A plus size denim pattern usually requires:

- A redesigned front and back rise curve

- Adjusted hip angle and depth

- Repositioned darts or shaping seams

- Rebalanced pocket placement

These changes are structural. They affect how the garment hangs, stretches, and recovers during wear.

Factories that treat plus size as a separate pattern system, rather than an extension of standard sizes, tend to achieve more stable results in bulk production.

How do body proportions affect fit outcomes in plus size denim?

One key mistake is assuming that all plus size customers share the same body shape.

In practice, plus size bodies show greater variation in:

- Waist-to-hip ratio

- Thigh volume

- Abdomen fullness

- Seat projection

This means that a single pattern adjustment rarely solves all fit complaints.

From a manufacturing standpoint, brands must decide early which body profile they are designing for. Without this decision, sampling becomes reactive, with repeated revisions that address one issue while creating another.

Clear fit intent reduces pattern changes later and helps factories control consistency in bulk.

How does stretch denim change plus size pattern decisions?

Stretch denim is often seen as a solution for plus size fit. It can help, but it also introduces new risks.

Stretch allows the fabric to adapt to movement, but it does not correct poor pattern balance. In some cases, stretch hides problems during fitting and exposes them after wear.

Key considerations include:

- Recovery matters more than stretch percentage

- Excessive stretch can increase waist growth after wear

- Poor recovery leads to sagging at the seat and knees

Many factories recommend controlled stretch for plus size denim rather than high stretch. Lower stretch with strong recovery allows the pattern to do most of the work, with fabric supporting comfort instead of compensating for design issues.

Why is rise design critical in plus size jeans?

Rise design is one of the most sensitive areas in plus size denim.

An under-designed rise causes:

- Pulling at the front

- Waistband rolling

- Discomfort when sitting

An over-designed rise leads to:

- Excess fabric at the back

- Poor seat appearance

- Unstable waistband positioning

Factories often adjust front and back rises independently in plus size patterns. This allows better balance between comfort and appearance.

Rise depth also interacts with fabric choice and washing. Denim that shrinks unevenly after washing can change rise behavior, making early testing essential.

How do plus size patterns behave differently during washing?

Washing amplifies pattern weaknesses.

In plus size denim, even small shrinkage differences can cause visible fit problems. Areas under higher stress, such as thighs and seat, react more strongly to washing and drying.

Common risks include:

- Uneven shrinkage across panels

- Twisting caused by unbalanced grain placement

- Loss of intended ease after wash

Factories often test plus size samples more aggressively before approval. This includes wash testing and wear simulation to observe how the garment settles after repeated use.

What role does grading play in plus size size ranges?

Plus size grading is not just about extending size numbers. It requires separate grading rules.

Many factories limit the number of sizes per pattern block to maintain control. Instead of grading continuously from core to extended sizes, they may split size ranges into different blocks.

This approach:

- Reduces extreme grading jumps

- Improves fit consistency across sizes

- Simplifies bulk quality control

While this adds development work early, it often reduces revisions and returns later.

Why do plus size jeans show higher return rates?

From production data, returns in plus size denim are rarely caused by defects. They are caused by unmet fit expectations.

Common customer complaints include:

- Waist gaps after wear

- Tightness in specific areas

- Inconsistent sizing between washes

These issues usually trace back to pattern logic rather than sewing quality. Brands that invest in early fit development tend to see fewer size-related returns, even if the initial process takes longer.

How do factories evaluate plus size fit before bulk production?

Factories look beyond fitting photos.

Evaluation often includes:

- Measuring stretch and recovery after wash

- Checking balance lines during movement

- Reviewing size-to-size consistency

Fit approval is not a single moment. It is a process that combines pattern checks, fabric testing, and wear feedback.

Clear communication between brand and factory helps align expectations and reduces last-minute changes.

How should brands approach plus size denim development?

The most stable approach is to treat plus size as its own development path.

This means:

- Defining fit priorities early

- Choosing fabric based on recovery, not softness alone

- Allowing extra time for pattern refinement

Factories prefer working with brands that understand that plus size fit is engineered, not adjusted. This shared understanding leads to smoother sampling and more predictable bulk results.

Final thoughts from the production floor

Plus size denim does not fail because bodies are complex. It fails when patterns are simplified too much.

Well-fitting plus size jeans are the result of careful pattern logic, fabric control, and realistic testing. When these elements work together, fit becomes consistent, wearable, and repeatable at scale.

For brands, the goal is not to eliminate all fit feedback. It is to reduce avoidable fit risk before production begins.

Related Reading

- Common Fit Issues in Jeans

- How Stretch Denim Affects Fit

- Men’s vs Women’s Fit Differences

- Sampling to Bulk Production