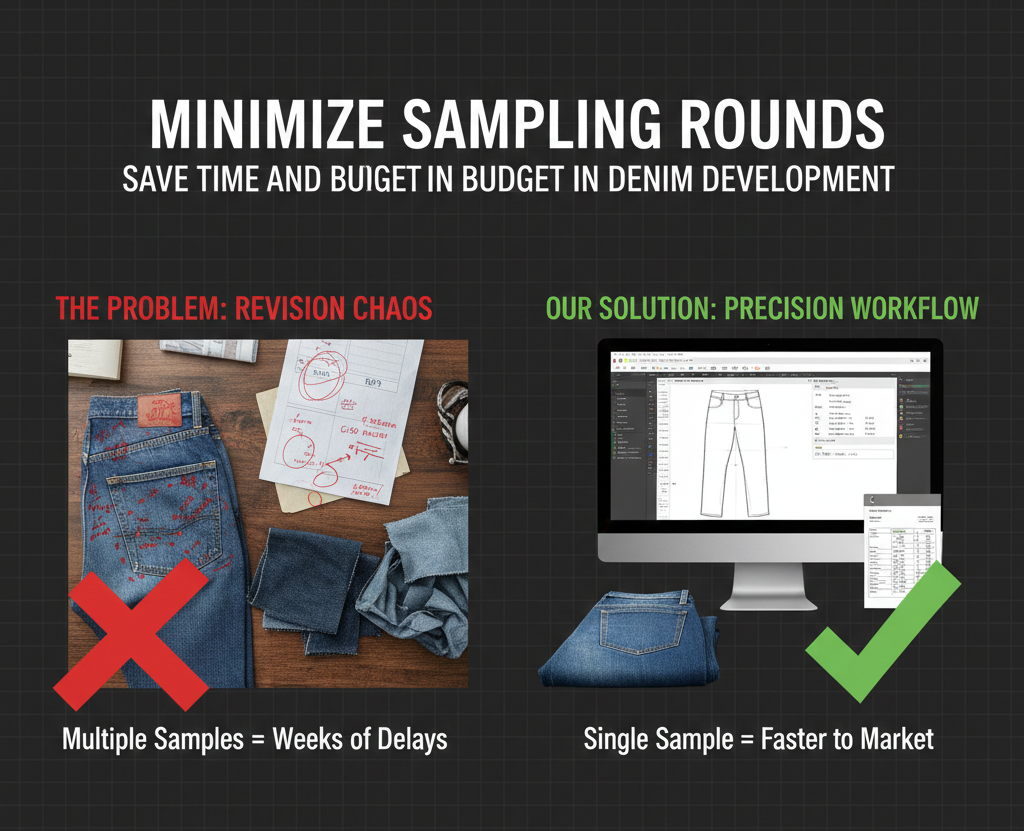

In the world of professional denim manufacturing, the phrase “let’s just make one more sample” is often the most expensive sentence a brand can say.

For many new founders and sourcing teams, sampling is seen as a creative trial-and-error process. However, from the factory floor’s perspective, every unnecessary revision is a symptom of a technical breakdown. When a prototype fails to meet expectations—whether it’s a pocket placement that feels “off” or a wash that looks too aggressive—the cost isn’t just the sample fee. The real cost is the 14-day delay in your production calendar, the wasted yardage of premium denim, and the potential loss of a seasonal sales window.

At Xinen Garment, we have observed that the difference between a brand that approves their bulk production in one round and a brand that struggles through four revisions is rarely about the design’s complexity. Instead, it is about how much technical clarity is established before the first yard of fabric is even cut. Achieving a “First-Time-Right” sample isn’t an accident of luck; it is the result of a specific engineering workflow that bridges the gap between a designer’s vision and the physical realities of denim construction.

Why Do Most Denim Samples Fail in the First Round?

To solve the problem of excessive sampling, we must first understand why the first proto often misses the mark. In our experience as a custom denim factory, the failure usually stems from three specific areas:

1. The “Visual vs. Physical” Gap

Many brands send inspiration photos from Pinterest or Instagram and expect the factory to reverse-engineer the fit and wash from a single 2D image. However, a photo does not tell us the fabric’s GSM, the elastane percentage, or the exact chemical sequence used in the wash. Without a technical specification, the factory is forced to guess. Guesswork leads to revisions.

2. Underestimating Shrinkage and Fabric Behavior

Denim is a living fabric. As discussed in our previous guide on [Denim Shrinkage Protocol], a 3% error in calculation can ruin a fit. If a brand provides a measurement chart but doesn’t specify the intended fabric, the pattern maker cannot compensate for how that specific fabric will “pull” or “stretch” during the industrial laundry process.

3. Vague Feedback Cycles

When a sample arrives, the feedback is often subjective: “It feels too tight,” or “The wash looks too dark.” Subjective feedback is difficult for a pattern maker or a wash technician to translate into technical adjustments. Does “too tight” mean the hip circumference needs an extra 2cm, or is the fabric’s recovery simply too high?

The Pre-Development Checklist: Setting the Stage for Success

Before we even start the sewing machine at Xinen Garment, we encourage our clients to go through a rigorous pre-development phase. This is the foundation of minimizing sampling rounds.

Complete the Tech Pack

A tech pack is the “blueprint” of your garment. A high-quality denim tech pack must include:

- Point of Measurement (POM) Chart: Exact measurements for every size.

- Bill of Materials (BOM): Details on threads, buttons, rivets, and zippers.

- Construction Details: Specifics on stitch types (e.g., chain stitch vs. lockstitch) and SPI (stitches per inch).

- Wash Targets: High-resolution photos of the front, back, and detail areas (whiskers, honeycombs) of the desired wash.

Fabric Alignment

Choosing fabric at the sampling stage is a commitment. You should never sample with a “substitute” fabric if you intend to use a different one for bulk. The way a 12oz 100% cotton rigid denim washes is fundamentally different from a 12oz 2% stretch denim. If you change the fabric between the first and second sample, you are essentially starting the process from zero.

Providing a Reference Garment

If you have a pair of jeans that fits exactly how you want your brand to fit, send them to the factory. Physical reference samples allow our technical team to measure the rise, the curve of the seat, and the leg opening with 100% accuracy. This removes the “interpretation” phase of development.

How Xinen Garment Engineers the “First-Time-Right” Sample

At our facility, we have implemented a technical pre-review process designed to catch errors before they become physical samples. This is how we protect our clients’ timelines.

Digital Pattern Simulation and CAD Review

Our pattern makers don’t just draw lines; they simulate fit. By using advanced CAD software, we can overlay your measurements against our library of proven fit blocks. If we see that your requested front rise is disproportionately short compared to the back rise, we will flag this to you before cutting the fabric. This consultative approach saves at least one revision round for most clients.

The “Blanket Test” Integration

As a professional denim manufacturer, we perform shrinkage tests on the fabric lot intended for your sample. By washing a 50cm x 50cm square of your fabric in the intended wash recipe first, we know exactly how many centimeters to add to the pattern. This ensures that the finished, washed sample matches your tech pack measurements.

Wash Prototype “Mastering”

Washing is the most unpredictable part of denim manufacturing. To minimize rounds, our wash technicians often create “wash swatches” on the actual fabric first. We send photos or physical swatches of these wash effects to the client for approval before applying the wash to the fully sewn garment.

Strategic Feedback: How Brands Can Speed Up Approval

The sampling process is a two-way street. How a brand handles the review of the first prototype determines how fast they can move to bulk production.

Consolidate Your Revisions

One of the biggest causes of “Sampling Hell” is fragmented feedback. Sending an email on Monday about the waist, another on Wednesday about the pocket shape, and a third on Friday about the thread color creates confusion. Wait until you have conducted a full fit session with your model, then send one comprehensive PDF with annotated photos.

Use Video Fittings

If you cannot be at the factory in person, a static photo of a sample on a mannequin is not enough. We recommend video fit sessions. Seeing how the denim moves, how the fabric “breaks” at the knee, and how it recovers after the model sits down gives the technical team much more information than a flat image.

Distinguish Between “Fit” and “Aesthetic”

Be clear about what needs to change. Is the problem the Pattern (the physical dimensions) or the Wash (the visual finish)? Usually, if the fit is 95% correct, we can move to a “Salesman Sample” or even a “Pre-Production Sample” (PPS) while making minor wash adjustments, rather than ordering an entirely new proto.

The Financial Reality: Why Fewer Rounds Mean Better Business

Reducing sampling rounds isn’t just about being organized; it’s about your bottom line.

- Lower Development Fees: Most factories charge a premium for samples (often 2x to 3x the bulk price). Reducing revisions keeps these costs down.

- Faster Market Testing: In the fast-moving fashion world, being two months late to market can mean the difference between a trend-setting launch and a clearance-rack failure.

- Better Factory Relations: Factories prefer working with organized brands. When a factory knows that a client provides clear tech packs and decisive feedback, they are more likely to prioritize that brand’s orders in the production queue.

FAQ: Common Questions About the Denim Sampling Process

Q: How many sampling rounds are considered “normal” in denim?

A: In a professional setup with a clear tech pack, 1 to 2 rounds should be the goal. The first is a “Proto Sample” for fit and construction; the second is a “Pre-Production Sample” (PPS) for final wash and trim approval. If you are on round 4 or 5, there is a fundamental communication or fabric alignment issue.

Q: Can I use a stock fabric for my sample and then choose a custom fabric for bulk?

A: We strongly advise against this. Because every denim fabric has a unique shrinkage and torque profile, a sample made in stock fabric will not accurately represent the fit of your bulk production. Always sample in the actual fabric you intend to sell.

Q: Why does my sample look different from the inspiration photo I sent?

A: Inspiration photos are often edited or taken under specific lighting. Furthermore, different fabrics absorb indigo dye differently. To get closer to your target, provide a physical reference garment rather than a digital image.

Q: Is the sample I receive exactly what the bulk production will look like?

A: The sample is a “Gold Standard.” However, because denim washing is a manual, artisanal process involving stones, enzymes, and hand-scraping, there is always a slight “commercial tolerance” in bulk. Our goal in sampling is to define the center point of that tolerance.

Q: How long does a typical sampling round take?

A: At Xinen Garment, a sampling round typically takes 10 to 14 days, depending on the complexity of the wash. This includes pattern making, cutting, sewing, and the multi-stage laundry process.

Conclusion: Fit is a Process, Not a Guess

At Xinen Garment, we don’t believe in the “trial and error” method of denim manufacturing. We believe in technical preparation. By aligning your fabric choice, tech pack accuracy, and feedback loop before production begins, you can bypass the common delays that plague most new collections.

Minimizing sampling rounds is the most effective way to protect your budget and ensure that your brand hits the market with a product that fits perfectly from day one.

Ready to start your next collection with a technical partner? Contact our development team today. We can review your current tech packs and provide a technical assessment to help you get your next sample right in the first round.