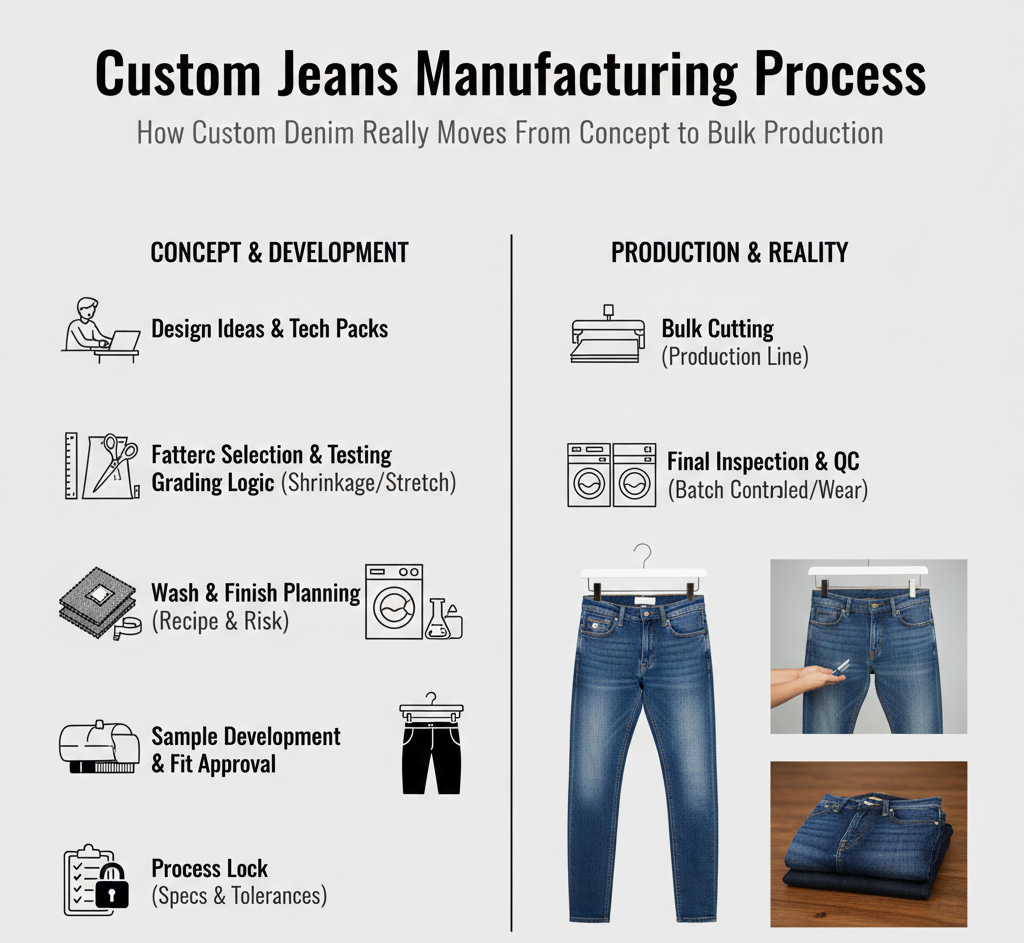

How Custom Denim Really Moves From Concept to Bulk Production

In custom denim production, most problems do not come from poor sewing or weak fabric.

They usually come from misunderstanding the manufacturing process.

Brands may believe something is already confirmed, while the factory sees it as a reference.

Designers may think a sample represents final production, while technical adjustments are still ongoing.

A stable custom jeans project is not built on one single step.

It depends on a clear, repeatable manufacturing process that connects design, development, and bulk production.

Below is how custom jeans are typically made inside a professional denim factory — based on real production logic, not idealized theory.

1. Turning Design Ideas Into Production-Ready Information

Most custom jeans projects start with one or more of the following:

- Design sketches

- Reference photos

- Vintage samples

- Competitor products

These materials are helpful, but they are not production documents.

The first task inside the factory is to translate design intent into technical language, including:

- Fit direction (straight, relaxed, tapered, wide, slim)

- Rise type (high, mid, low)

- Target wearer (men, women, plus size, unisex)

- Fabric weight range

- Stretch requirement or non-stretch structure

This is where many misunderstandings begin.

Words like “slightly loose” or “vintage fit” can mean very different things to different teams.

An experienced factory will not move directly to sampling. Instead, it will clarify what can realistically be produced and worn.

2. Pattern Development: The Foundation of Fit

Pattern development is not about copying an existing size or scaling up a basic block.

For custom jeans, the pattern defines the entire product experience.

A proper pattern process usually includes:

● Base pattern creation

Based on the target body shape and market, not a generic template.

This includes decisions on:

- Waist-to-hip ratio

- Thigh and knee balance

- Front and back rise length

- Leg opening proportion

● Size logic confirmation

Before grading begins, brands need to clarify:

- Size range structure

- Whether plus size requires independent pattern logic

- How consistent the fit should feel across sizes

Many bulk production issues trace back to unclear sizing logic, not sewing quality.

3. Fabric Selection Is About Stability, Not Price

Choosing denim fabric is rarely about “better” or “worse”.

It is about whether the fabric works with the intended design and process.

Factories typically evaluate:

- Fabric weight suitability for the pattern

- Weave density and shrinkage risk

- Stretch yarn percentage and recovery

- Compatibility with washing techniques

For example:

- High-stretch denim may feel comfortable but requires tighter wash control

- Lightweight denim needs stronger pattern balance to avoid distortion

Professional recommendations focus on production consistency, not just appearance.

4. Wash and Finish Planning Happens Early

Washing is not a final decoration step.

It is part of the manufacturing design.

During development, wash plans usually define:

- Pre-shrink methods

- Enzyme, stone, or abrasion intensity

- Manual versus machine-controlled effects

- Expected size change after wash

One key reality:

A sample can be manually adjusted. Bulk production cannot.

That is why reliable factories avoid wash effects that cannot be repeated at scale.

Wash development is about control, not creativity alone.

5. Sample Development Is a Process, Not a One-Time Event

In custom denim, it is uncommon to approve everything in one sample.

A typical flow looks like:

- First sample: confirms direction and construction

- Second sample: adjusts fit, wash, or balance

- Third sample: final detail and size verification

Each sample stage reduces future risk.

If a factory promises one sample to bulk, it often means unresolved issues are pushed into production.

6. Preparing for Bulk: Locking the Process

Sample approval does not automatically mean bulk production starts.

Before production, factories usually finalize:

- Grading and size specs

- Technical construction sheets

- Fabric and trim inspection

- Wash parameter locking

The goal is to remove personal judgment and rely on repeatable procedures.

This is where experienced factories differ from small workshops.

7. Bulk Production: Consistency Over Speed

Bulk denim production typically follows these stages:

- Cutting (with shrinkage allowance)

- Sewing (divided into controlled operations)

- Washing (batch-controlled)

- Finishing and shaping

During production, attention is paid to:

- Batch variation

- Wash-before and wash-after measurements

- Structural issues such as leg twist or imbalance

Two factories can follow the same design and still deliver very different results — process discipline makes the difference.

8. Final Inspection Is About Wearability, Not Perfection

Final inspection is not about finding minor thread issues.

It focuses on:

- Measurement tolerance

- Wash consistency

- Natural drape when worn

- Structural integrity after finishing

For brands selling internationally, this step directly affects:

- Return rates

- Customer feedback

- Long-term brand trust

9. Why Understanding the Manufacturing Process Matters for Brands

When problems happen, brands often assume the factory failed.

In reality, many issues originate from early-stage decisions.

Understanding the full manufacturing process helps brands:

- Make better design choices

- Allocate development time more effectively

- Control cost without sacrificing stability

This knowledge becomes more valuable as collections grow.

Final Thoughts

Custom jeans are not fast products.

They require patience, testing, and clear communication.

But when the manufacturing process is understood and respected:

- Samples match bulk production more closely

- Quality becomes predictable

- Long-term collaboration becomes possible

For brands serious about denim, mastering the process is not optional — it is part of building a reliable product line.