A Practical Manufacturing Guide for Brands, Designers, and New Labels

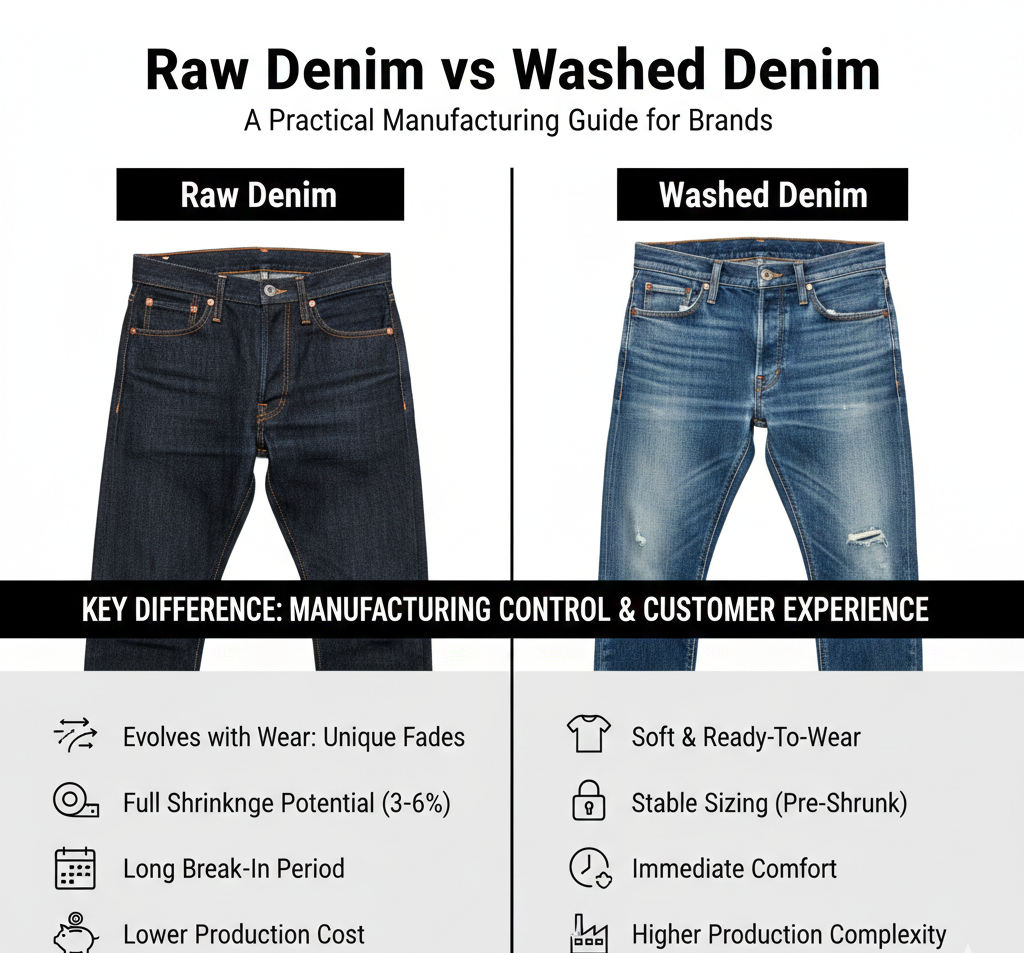

When developing a denim collection, one of the first decisions that affects almost every step after is whether to work with raw denim or washed denim.

On paper, the difference looks simple.

Raw denim feels authentic and evolves with wear.

Washed denim looks finished and ready for the customer.

But once you move from design to sampling, and from sampling to bulk production, this choice starts to affect far more than appearance. It impacts fit stability, fabric yield, wash risk, cost control, MOQ strategy, and even how many customer complaints you may receive after launch.

Understanding how raw and washed denim behave starts with knowing the fabric itself.

For a broader overview, see Denim Fabrics Explained.

This guide does not aim to tell you which option is “better.” Instead, it explains how raw and washed denim behave differently in real manufacturing, and what brands should consider before locking in either direction.

1. What Is Raw Denim, in Production Terms?

Raw denim (also called dry denim or unwashed denim) is denim fabric that has not gone through any garment washing or finishing after weaving and dyeing.

In most cases, raw denim is:

- Indigo dyed (rope-dyed or slasher-dyed)

- Cut and sewn without any wash treatment

- Shipped in its original, stiff state

From a factory point of view, raw denim is not “unfinished.” It is simply a fabric that has not yet been altered by washing, abrasion, or chemicals.

Because of this, raw denim keeps:

- The original fabric width and density

- The original yarn tension

- The full shrinkage potential

This makes raw denim very predictable in fabric form, but less predictable in final garment behavior once worn and washed by the end customer.

2. What Is Washed Denim, from a Manufacturing Perspective?

Washed denim refers to garments that have undergone one or more washing or finishing processes after sewing.

These processes may include:

- Rinse wash

- Enzyme wash

- Stone wash

- Vintage or faded wash

- Softener or resin treatments

The goal of washing is not only visual. It also changes how the garment feels, fits, and behaves over time.

From the factory side, washed denim means:

- The fabric has already released part of its shrinkage

- The garment shape is more stable at delivery

- Visual variation becomes a controlled variable

Washed denim is closer to the final experience the customer will have on day one.

Washing does not affect all denim the same way. The impact becomes even more complex when stretch fibers are involved, as explained in our guide on Stretch vs Non-Stretch Denim.

3. The Real Difference Is Not Look — It’s Control

Many brands compare raw and washed denim based on aesthetics. In production, the bigger difference is control.

Raw denim gives more control before washing, but less control after the product reaches the customer.

Washed denim reduces uncertainty for the end user, but increases complexity during manufacturing.

This trade-off is often underestimated during early development.

4. Fit Behavior: Sample Stage vs Bulk Reality

Raw Denim Fit Behavior

At sampling stage:

- The fit often feels stiff

- Waist and hip feel tighter

- Buyers assume the garment will “break in”

In bulk production:

- All garments are consistent at shipment

- No wash variation between pieces

- Fabric behavior is stable at factory level

After customer use:

- Shrinkage occurs after first wash

- Fit changes depend on washing habits

- Customer education becomes critical

Factories often see fit complaints not because raw denim was poorly made, but because shrinkage expectations were not clearly communicated.

Washed Denim Fit Behavior

Washing does not affect all denim the same way. The impact becomes even more complex when stretch fibers are involved, as explained in our guide on Stretch vs Non-Stretch Denim.

At sampling stage:

- Fit feels closer to final wear

- Buyers can assess comfort immediately

- Size feedback is more reliable

In bulk production:

- Wash variation must be tightly controlled

- Small changes in wash time or temperature can affect size

- Pattern allowances must match wash loss precisely

The advantage is that once delivered, the garment size remains more stable for the customer.

5. Shrinkage: Where Most Decisions Go Wrong

Shrinkage is the most misunderstood factor when choosing between raw and washed denim.

Raw Denim Shrinkage Reality

Even sanforized raw denim still carries residual shrinkage. Typical shrinkage ranges:

- Length: 3–6%

- Width: 2–4%

This shrinkage happens after the customer washes the garment, not in the factory.

From a brand standpoint, this means:

- Size charts must account for post-wash behavior

- Customer expectations must be managed

- Returns often happen after first wash, not first wear

Washed Denim Shrinkage Reality

For washed denim:

- Most shrinkage is already released

- Final garment dimensions are closer to stable

- Customer wash impact is lower

However, this stability depends on:

- Accurate wash testing during development

- Consistent bulk washing conditions

- Fabric batch consistency

Poor wash control leads to size variation inside the same order, which is harder to fix than raw denim shrinkage complaints.

6. Washing Risk and Production Complexity

Raw Denim: Lower Factory Risk, Higher User Risk

From the factory side:

- No washing reduces production steps

- Lower processing cost

- Lower rejection rate during manufacturing

From the brand side:

- Risk shifts to the customer

- More after-sales education required

- Fit complaints may appear weeks later

Washed Denim: Higher Factory Risk, Lower User Risk

For washed denim:

- Each wash step introduces variation

- Rejection risk increases

- More QC checkpoints are required

But for the end user:

- Fit and feel are predictable

- Less learning curve

- Higher immediate satisfaction

Brands must decide where they prefer to absorb risk: inside the factory or after the product is sold.

7. Cost Structure: What Changes and Why

Raw Denim Cost Structure

Raw denim is often assumed to be cheaper. This is not always true, but generally:

- No washing cost

- Lower labor and water usage

- Simpler QC process

However:

- Higher return rates can offset savings

- Customer support costs may increase

- Branding relies more on education, not finish

Washed Denim Cost Structure

Washed denim adds cost through:

- Washing labor

- Chemicals and water

- Energy and wastewater treatment

- Higher rejection rates

But:

- Finished look increases perceived value

- Easier to justify higher retail pricing

- Lower post-sale issues

Cost should be evaluated across the full product lifecycle, not only FOB price.

8. Durability and Aging Over Time

Fabric weight plays a major role in how both raw and washed denim age over time. Heavier denim tends to hold structure better, which we explain in detail in Denim Weights Explained.

Raw Denim Aging

Raw denim ages through wear, not design.

- Creases form naturally

- Color fades according to use

- Each garment becomes unique

This appeals to:

- Heritage brands

- Denim enthusiasts

- Long-term wear customers

However, durability depends heavily on:

- Fabric weight

- Yarn quality

- Stitching and reinforcement

Washed Denim Aging

Washed denim starts with a defined look.

- Fades are pre-set

- Softness is immediate

- Aging is slower and less dramatic

Over time:

- Additional wear adds less visible change

- Durability depends on wash aggressiveness

Over-washed denim may look good initially but weaken faster if not engineered correctly.

9. MOQ and Production Planning

Raw denim generally allows:

- More flexible MOQs

- Easier fabric substitution

- Faster production lead times

Washed denim often requires:

- Minimum wash batch quantities

- Locked wash recipes

- Stable bulk volume to reduce variation

For small brands or first collections, this difference can strongly affect feasibility.

10. Common Mistakes Factories See

From a factory viewpoint, these mistakes appear often:

- Choosing raw denim without planning customer education

- Applying heavy vintage concepts to raw denim expectations

- Underestimating wash complexity in washed denim

- Approving wash samples without tolerance testing

- Treating raw and washed denim patterns the same

Most production problems do not come from sewing, but from early fabric and process decisions.

11. How Brands Can Decide More Rationally

Instead of asking “Which one is better?”, consider these questions:

- Do you want the garment to evolve, or stay consistent?

- Can your customer accept change after washing?

- Is your brand story strong enough to explain raw denim behavior?

- Do you have budget room for wash development and QC?

- Are returns more costly than higher production cost?

If the answer is unclear, some brands start with:

- Lightly washed denim as a middle ground

- Or test raw denim in limited runs before scaling

12. Which Brands Tend to Choose Which Option?

There is no strict rule, but patterns do exist.

Raw denim is more common in:

- Heritage-inspired brands

- Men’s classic denim

- Niche or enthusiast-focused labels

Washed denim is more common in:

- Fashion-driven collections

- Women’s denim

- DTC brands focused on first-wear comfort

The choice should match not only the product, but the customer’s expectations and tolerance.

Final Thoughts from the Factory Floor

Raw denim and washed denim are not opposing styles. They represent different ways of managing risk, control, and customer experience.

Strong brands do not choose based on trend or cost alone. They choose based on how the product will behave after it leaves the factory.

Understanding that behavior early is what turns a denim idea into a scalable product.

Choosing raw or washed denim is only one part of the equation. How that choice is managed during sampling and bulk production matters just as much. You can learn more in our guide to Quality Control in Denim Production.

Related Guides

- Denim Fabric Types Explained

- Denim Weights Explained

- Stretch vs Non-Stretch Denim

- How Denim Washing Changes Fit

- Quality Control in Denim Production