How Custom Jeans Are Actually Made — From Development to Bulk Production

In denim manufacturing, most problems do not start on the sewing line.

They start much earlier — during development decisions that look small at the time but become expensive in bulk production.

This Manufacturing Process hub explains how custom jeans are really made in a factory environment. Not the ideal version, but the practical one brands deal with when moving from concept to mass production.

If you are developing your first jeans collection, refining an existing fit, or scaling from samples to bulk orders, understanding this process helps you ask better questions and avoid common production risks.

Why understanding the manufacturing process matters for denim

Jeans are not a simple cut-and-sew product.

Fabric behavior, washing processes, shrinkage, stretch recovery, and construction tolerance all interact with each other.

When brands treat production as a single step, problems usually show up later as:

- Fit changes after washing

- Bulk quality not matching samples

- High rejection rates during inspection

- Unexpected delays and rework costs

Understanding the full process helps brands plan development more realistically and work more effectively with factories.

What this manufacturing process hub covers

This hub focuses on process logic, not sales claims.

Each sub-page breaks down one critical stage in jeans manufacturing.

🔹 Custom Jeans Manufacturing Process

How a custom jeans order moves from concept to finished product, including fabric selection, pattern development, sampling, washing, and bulk production planning.

→ Best for brands who want a full-picture understanding before placing orders.

🔹 Sampling to Bulk Production

Why approved samples do not always guarantee smooth bulk production, and what changes when production scale increases.

→ High value for first-time brands and small teams scaling production.

🔹 Quality Control in Denim Production

How quality is checked during denim production, not just at final inspection, and where most quality issues actually originate.

→ Useful for brands struggling with inconsistency or returns.

🔹 Common Production Mistakes Brands Make

Real production mistakes we see repeatedly in jeans manufacturing — and why they happen even when samples look perfect.

→ Helps brands avoid repeating costly development errors.

How custom jeans manufacturing actually works in practice

Most brands imagine production as a straight line.

In reality, it works more like a loop.

Decisions made during fabric selection affect pattern behavior.

Pattern adjustments affect washing results.

Washing results affect final fit and measurement tolerance.

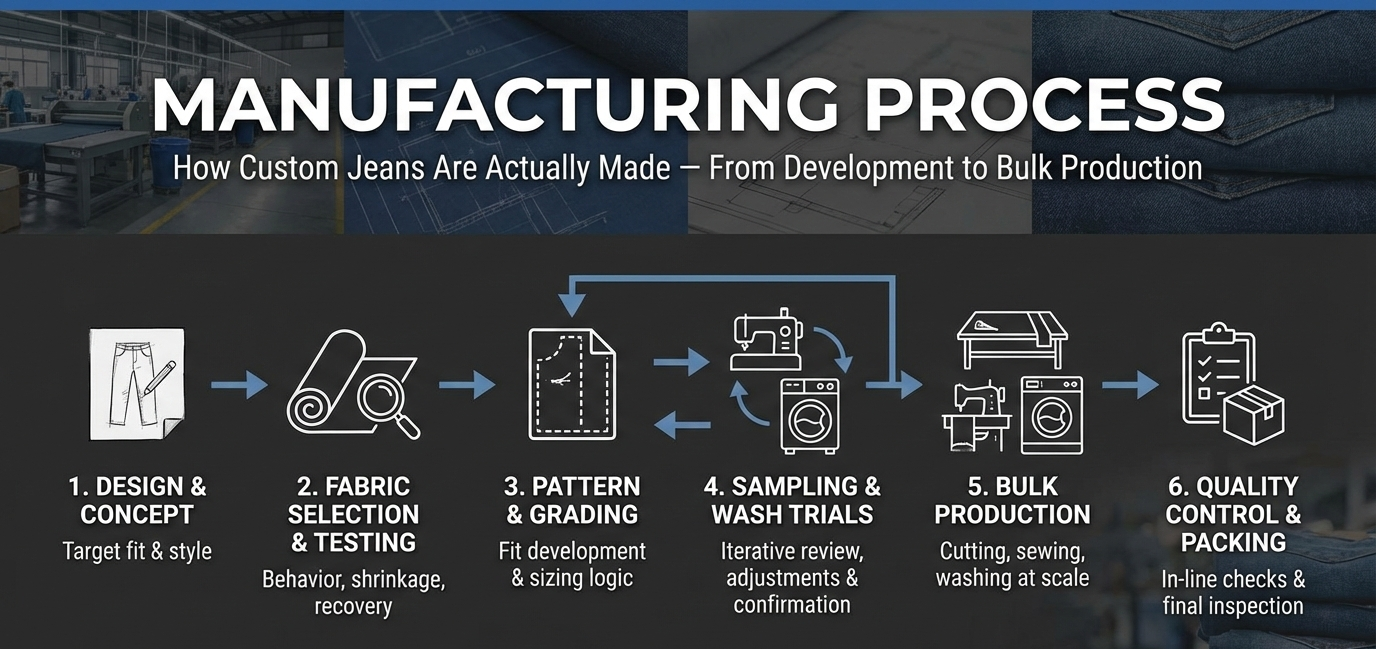

A simplified flow looks like this:

- Design concept and target fit

- Fabric selection and testing

- Pattern development and grading

- Sample sewing and wash trials

- Fit review and adjustments

- Pre-production confirmation

- Bulk cutting, sewing, washing

- In-line and final quality checks

Each step influences the next. Skipping or rushing one step often leads to problems later.

Why denim production is different from other garments

Compared to T-shirts or woven tops, jeans involve more variables:

- Fabric shrinkage after washing

- Stretch recovery loss over time

- Wash effects on size and shape

- Construction stress points (waistband, hips, knees)

Because of this, denim production requires more testing and coordination between development, washing, and production teams.

This is why factories experienced in denim often approach development more cautiously than general garment factories.

What brands often underestimate during production

From a factory perspective, these are common gaps we see:

- Assuming bulk fabric behaves exactly like sample fabric

- Locking fit before wash testing is complete

- Treating washing as a visual process, not a technical one

- Expecting quality control to “fix” development issues

- Making late-stage design changes after bulk materials are ordered

These issues are not caused by lack of effort — usually by lack of process clarity.

How this hub helps you work better with a denim factory

You do not need to manage production yourself.

But knowing how the process works helps you:

- Communicate requirements more clearly

- Understand factory feedback earlier

- Set realistic timelines

- Reduce costly revisions

- Make better decisions during development

Brands that understand manufacturing logic tend to move faster with fewer mistakes, even with small teams.

Who this Manufacturing Process hub is for

This content is especially useful if you are:

- Launching your first jeans collection

- Switching denim suppliers

- Experiencing fit or quality issues in bulk

- Scaling from sampling to larger orders

- Working with overseas denim factories

If you already have stable production, these pages still help identify where improvements can be made.

Explore the manufacturing process in detail

If you want to go deeper, start with these pages:

- Custom Jeans Manufacturing Process → Full production overview

- Sampling to Bulk Production → Where most risks appear

- Quality Control in Denim Production → How consistency is maintained

- Common Production Mistakes Brands Make → What to avoid early

Each page focuses on one part of the process, so you can read only what is relevant to your current stage.

Final note from the factory side

Good denim production is not about perfection.

It is about making informed trade-offs at the right time.

Understanding the manufacturing process helps brands make those decisions earlier — when changes are still manageable, and costs are still under control.