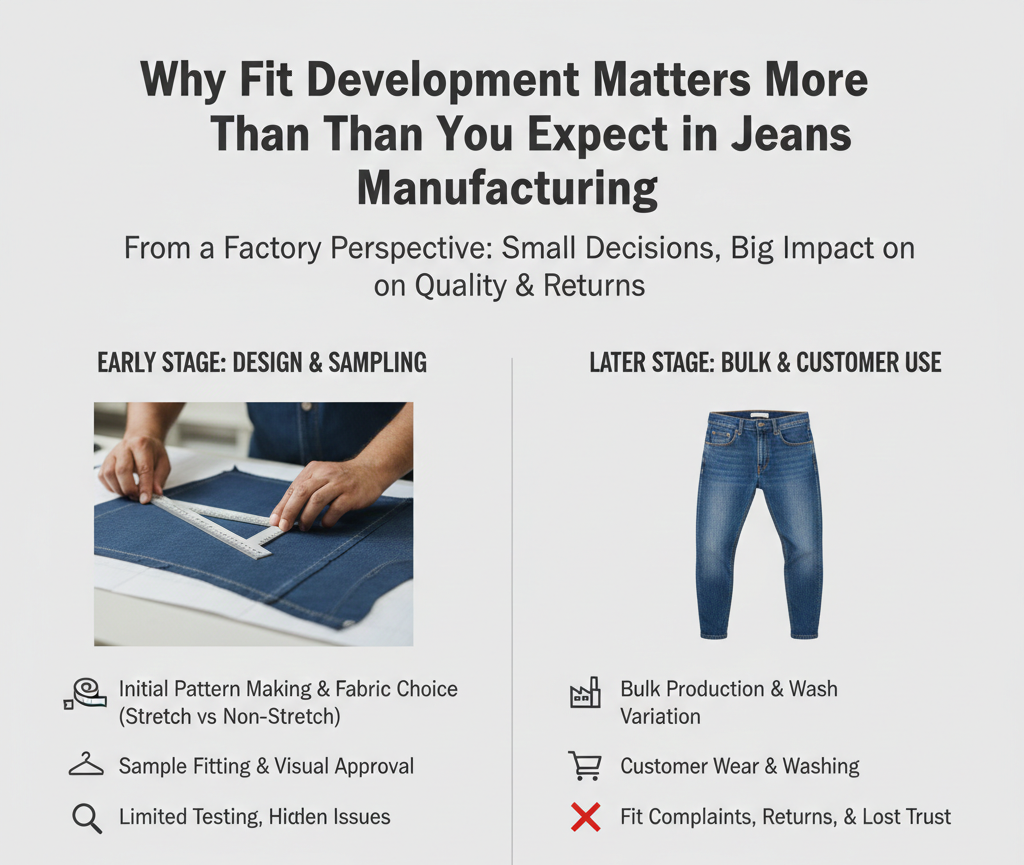

Many brands enter denim development believing fit is something that can be adjusted late in the process. A few tweaks to the pattern, a tighter tolerance here, a looser seam there — problem solved.

In real production, fit does not work that way.

Fit decisions made early quietly shape everything that follows: fabric choice, wash stability, grading logic, size consistency, return rates, and even long-term customer trust. When fit development is rushed or underestimated, problems rarely show up in sampling. They appear later — in bulk production, after washing, or once real customers start wearing the jeans.

Why do fit problems rarely come from a single mistake?

When brands face fit complaints, the first instinct is often to look for one clear error: a wrong measurement, a sewing issue, or a grading mistake.

In reality, most fit problems are the result of small decisions stacking up.

A pattern drafted for non-stretch denim is used on stretch fabric without adjustment.

A wash program slightly alters shrinkage expectations.

A size set is approved based on visual fit, not wear testing.

Individually, none of these choices seem serious. Together, they create jeans that look fine on a fit model but behave differently on real bodies.

From a factory point of view, fit issues are rarely dramatic failures. They are gradual mismatches between design intent and production reality.

Why does a sample fit well, but bulk production feels different?

This is one of the most common frustrations we hear from brands.

Sampling is controlled. Bulk production is not.

In sampling, fabrics often come from limited rolls, washing loads are small, and garments receive more individual handling. In bulk, fabric batches vary, machines run at scale, and slight tolerances matter more.

Fit problems in bulk usually come from:

- Fabric stretch recovery changing between lots

- Heat exposure during washing affecting dimensions

- Sewing tension differences across production lines

None of these are obvious at the sample stage. That is why fit development should never rely on a single “perfect” sample. It needs margin, testing, and realistic expectations.

Does stretch denim really make fit easier?

Stretch denim is often chosen because it feels forgiving. It allows movement, feels comfortable during fitting, and can mask minor pattern issues.

But stretch does not remove fit risk — it changes the type of risk.

If stretch recovery is weak, jeans may feel good at first wear and lose shape after a few hours. Knees bag out. The seat drops. Waistbands relax more than expected.

From a production view, stretch denim requires:

- Controlled recovery testing

- Adjusted pattern tension

- Wash programs that protect elastane

Without these, stretch denim can increase return rates rather than reduce them.

Why do fit issues often appear after washing, not before?

Before washing, most denim garments look correct on a mannequin or fit model. Washing introduces stress — heat, moisture, agitation — that reveals weaknesses in fit planning.

Common post-wash issues include:

- Unexpected shrinkage in waist or inseam

- Twisting seams

- Changes in rise depth

- Loss of stretch recovery

These are not washing “mistakes” alone. They are signs that fit development did not fully account for fabric behavior under real finishing conditions.

Factories tend to trust washed fit more than raw fit because washing shows how a garment will actually reach the customer.

How early fit decisions affect grading and size consistency

Fit is not only about one size.

Once the base pattern is approved, grading spreads that logic across the entire size range. If the base fit has tension issues, every size inherits them.

For example:

- A tight hip in size M becomes a severe restriction in size XL

- A relaxed waist recovery feels acceptable in size S but unstable in larger sizes

Good fit development considers how the pattern behaves across sizes, not just how one model looks in one sample.

This is especially important for brands offering extended size ranges.

Why do men’s and women’s jeans require different fit logic?

Men’s and women’s jeans are often treated as similar products with different measurements. In practice, the fit logic is very different.

Women’s jeans must account for:

- Waist-to-hip ratio variation

- Body shape diversity

- Higher sensitivity to rise and seat comfort

Men’s jeans tend to focus more on:

- Leg balance

- Ease through thigh and knee

- Stability over repeated wear

Using the same development approach for both usually leads to compromise fits that satisfy neither group.

Can rushing fit development really save time or cost?

Skipping fit rounds often feels like a shortcut, especially for new brands facing tight timelines.

In production, rushed fit development usually leads to:

- Re-sampling

- Size complaints

- Reorders with corrections

- Higher customer service costs

The time saved early is often paid back later — with interest.

Factories see that brands who invest more time upfront in fit tend to move faster in later collections because the foundation is stable.

Why do fit problems impact returns more than price or branding?

Customers may tolerate price changes. They may even forgive fabric differences. Fit issues are personal.

If jeans feel wrong, customers return them — even if they love the brand.

From after-sales data, fit-related returns often exceed complaints about color, wash, or fabric quality. That is why experienced brands treat fit development as a business decision, not just a design step.

How do experienced factories approach fit development differently?

Factories that handle long-term denim programs focus less on visual approval and more on behavior.

They look at:

- How the garment moves

- How it recovers after wear

- How it changes after washing

- How it scales across sizes

Fit development becomes a process, not a moment.

This approach reduces surprises in bulk and builds consistency over time.

When should brands invest more in fit development?

Fit development deserves more attention when:

- Launching a first jeans collection

- Introducing new fabrics or washes

- Expanding size ranges

- Targeting repeat customers

In these cases, fit is not just a technical detail — it is part of the product promise.

Final thoughts from a production perspective

Fit development is easy to underestimate because its value is quiet. When done well, nothing goes wrong. When done poorly, problems surface late and cost more to fix.

Brands that grow sustainably usually learn this early: good fit does not come from fixing mistakes. It comes from preventing them.