Custom Denim Manufacturer for Brands and Private Labels

Finding the right custom denim manufacturer is not only about production capacity.

For most brands, the real concern is whether a factory understands denim as a product, not just as a garment.

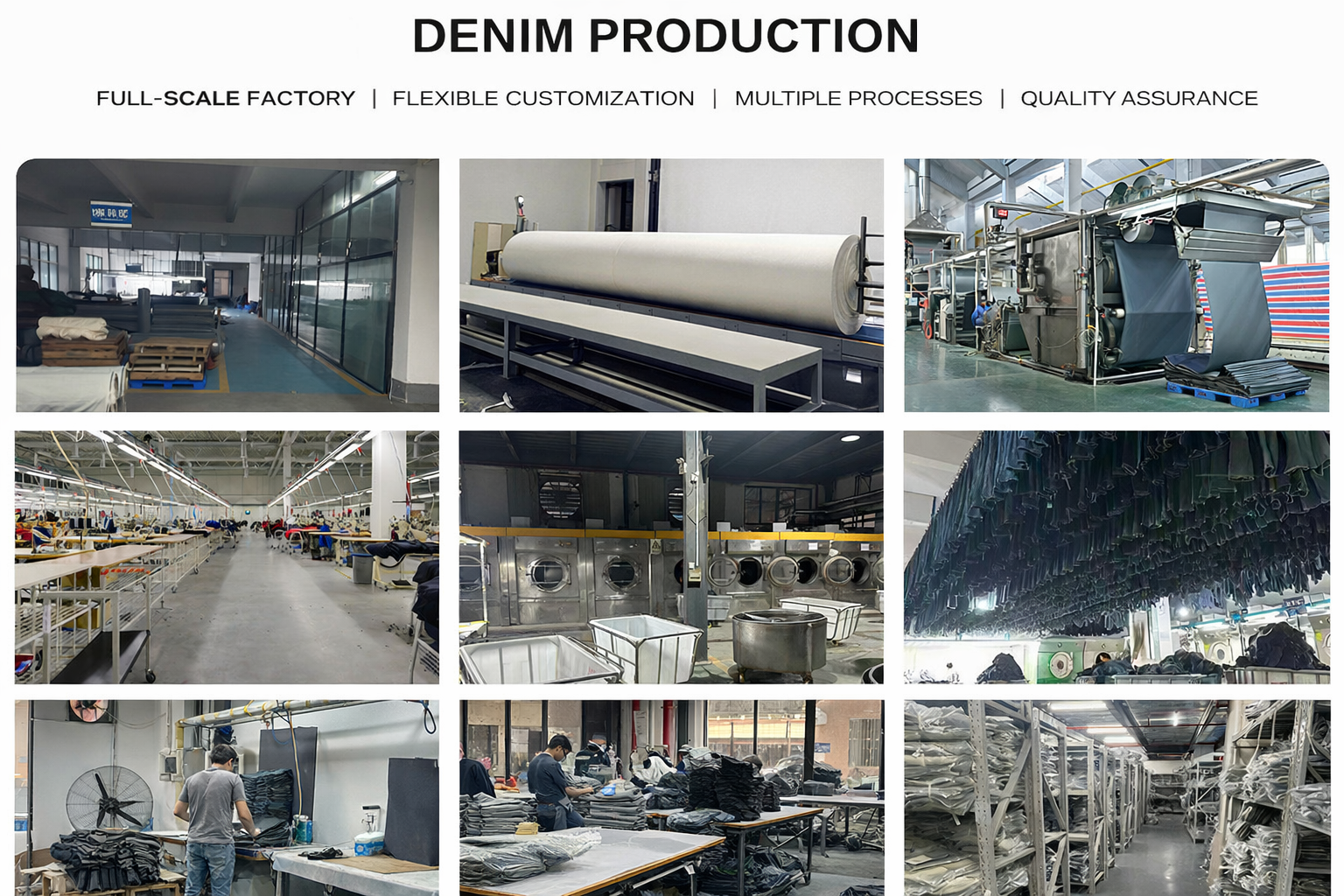

As a custom denim manufacturer, our role is to support brands through fabric selection, pattern development, washing control, and bulk production with stable quality. We work with brands that value consistency, fit accuracy, and long-term production reliability rather than one-time orders.

This page explains how we approach custom denim manufacturing, what we can support, and how we typically work with brands from development to bulk production.

What Custom Denim Manufacturing Means in Practice

Custom denim manufacturing is more than adding a logo to existing styles.

In real production, it involves:

- Selecting the right denim fabric based on fit, wash, and end use

- Adjusting patterns according to fabric behavior

- Controlling shrinkage and measurement changes during washing

- Maintaining consistency between samples and bulk orders

Each decision made at the early stage will directly affect bulk production results. This is why denim requires a different approach compared to basic knit or woven garments.

Denim Fabric Selection Based on Product Needs

Denim fabric choice is one of the most critical steps in custom jeans development.

We support brands with:

- Stretch and non-stretch denim options

- Different fabric weights and constructions

- Cotton-based and blended denim fabrics

- Fabrics suitable for clean, vintage, or light distressed finishes

Rather than recommending a single solution, fabric selection is usually discussed based on:

- Target customer and wearing habits

- Fit direction and pattern structure

- Washing level and finishing plan

- Long-term wear expectations

This approach helps reduce fit and quality issues during bulk production.

Pattern Development and Fit Control

Fit is one of the most common challenges in denim production.

As a custom denim manufacturer, we place strong emphasis on pattern development and fit adjustment. Denim fabric behavior varies significantly depending on stretch ratio, weight, and washing method, which means patterns cannot be treated as fixed templates.

Our pattern development process typically includes:

- Adjusting patterns based on fabric characteristics

- Reviewing fit balance before washing

- Testing measurement changes after washing

- Refining patterns before bulk confirmation

This process is especially important for:

- Slim and fitted styles

- Women’s jeans

- Men’s Jeans

- Plus size denim

- Styles with stretch denim

Proper pattern control helps reduce size deviations and improves wear comfort.

Washing and Finishing Control in Denim Production

Washing plays a major role in the final appearance and fit of denim garments.

We support various washing and finishing techniques, including:

- Clean and minimal washes

- Enzyme and stone washing

- Vintage-style finishes

- Controlled distressed effects

During washing, denim garments are exposed to heat, water, and mechanical action, which can affect fabric strength, elasticity, and measurements. For this reason, washing processes are planned according to fabric type and style requirements.

Stretch denim, in particular, requires careful control to avoid distortion or loss of recovery.

Sampling Process for Custom Denim Orders

Sampling is a key stage in custom denim manufacturing.

A typical sampling process includes:

- Development sample based on tech pack or reference

- Fit sample for measurement and wearing review

- Wash sample to confirm final appearance

- Pre-production sample before bulk

Each sample stage allows adjustments to be made before moving forward. This helps minimize risks during bulk production and ensures alignment between brand expectations and factory execution.

Bulk Production and Quality Control

Once samples are approved, bulk production begins.

Quality control in denim production focuses on:

- Fabric inspection before cutting

- Measurement consistency during sewing

- Wash result consistency

- Final garment inspection

Because denim is sensitive to process variation, maintaining stable production conditions is important. Our production flow is designed to reduce deviations between batches and ensure repeatability for ongoing orders.

Working with Private Label and Custom Denim Brands

We work with a wide range of brands, including:

- Private label brands

- Emerging denim labels

- Established apparel brands expanding denim lines

Each brand has different development needs. Some require support from fabric selection to bulk production, while others come with finalized designs and technical specifications.

Our role as a custom denim manufacturer is to adapt to these working styles and provide practical production support based on real manufacturing conditions.

Communication and Production Transparency

Clear communication is essential in custom denim manufacturing.

We typically communicate with brands on:

- Fabric and construction feasibility

- Fit and pattern adjustments

- Washing risks and limitations

- Production timelines and order planning

This helps avoid misunderstandings and ensures smoother development and production cycles.

Why Brands Choose a Specialized Denim Manufacturer

Denim production involves more variables than many other garment categories.

Working with a manufacturer that specializes in denim helps brands manage these variables more effectively.

Brands often look for:

- Stable fabric sourcing

- Experienced pattern and wash teams

- Consistent bulk quality

- Long-term production reliability

These factors matter more than short-term output volume.

Custom Denim Manufacturing as a Long-Term Partnership

For most brands, denim is not a one-season product.

Fit refinement, wash adjustment, and fabric optimization often continue across multiple seasons. A stable manufacturing partner allows brands to build on previous developments rather than restarting each time.

As a custom denim manufacturer, we focus on supporting this long-term development process with practical manufacturing experience and consistent execution.

Get Started with Custom Denim Manufacturing

If you are developing custom denim products and looking for a manufacturer with denim-focused experience, understanding each step of the process is the first step toward stable production.

You can contact us to discuss your denim project, development requirements, and production planning in more detail.