Launching your first jeans collection is exciting, but it can also feel overwhelming. Many new brands focus heavily on fit, wash, or branding, while fabric decisions are often made too quickly. From a factory point of view, denim fabric is not just a material choice. It affects fit accuracy, production stability, cost control, and long-term reorder consistency.

This article is written for brand founders, designers, and small teams who are preparing their first denim styles. Instead of trends or marketing language, we will explain how denim fabrics are evaluated in real production, what usually causes problems in first collections, and how to make choices that are reasonable for your stage.

There is no single “best” denim fabric. The right choice depends on your product goal, customer group, and production plan.

1. Why Fabric Choice Matters More Than Most First-Time Brands Expect

In early development, many brands choose denim based on hand feel or fabric weight alone. These are important, but they are only part of the picture.

From manufacturing experience, fabric choice directly influences:

- Pattern accuracy and grading results

- Shrinkage control after washing

- Sewing difficulty and defect rate

- Wash consistency between samples and bulk

- Final garment cost and delivery risk

For a first collection, the main goal is not complexity. It is stability. A fabric that behaves predictably in cutting, sewing, and washing will help you move from sample to bulk with fewer surprises.

2. Start With Your Product Direction, Not the Fabric Swatch

Before selecting fabric, clarify three basic questions:

- Who will wear these jeans?

- How will they be worn in daily life?

- What price range is realistic for your brand?

For example:

- A slim-fit women’s jean for daily wear has different fabric needs than a rigid vintage men’s style.

- A DTC brand selling online may need more stretch tolerance to reduce size-related returns.

- A premium brand may accept higher fabric cost but less wash variation.

Fabric choice should support the product purpose, not compete with it.

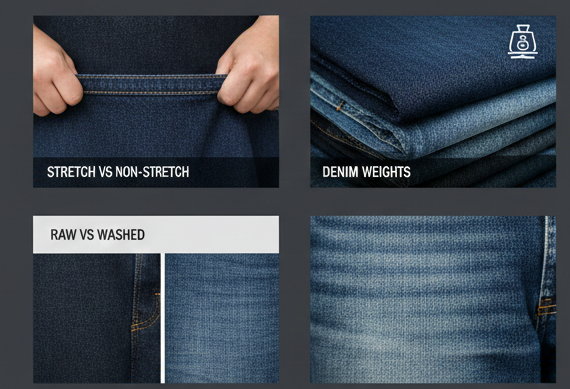

3. Understanding Denim Weight: What GSM Really Means in Production

Denim weight is often discussed in ounces (oz), but in factories we focus more on GSM and how the fabric behaves after washing.

General guidance:

- 8–10 oz: Lightweight denim, often used for summer styles or wide-leg fits

- 10–12 oz: Common for first collections, easier to control

- 12–14 oz: Traditional denim weight, more structure

- 14 oz and above: Rigid or heritage styles, higher production risk

For a first collection, many factories recommend 10–12 oz denim. It balances structure and manageability. It is easier to sew, more forgiving in washing, and has lower shrinkage risk compared to heavier fabrics.

Heavier denim is not wrong, but it requires more experience in pattern allowance and washing control.

4. Stretch vs Non-Stretch: A Practical Decision, Not a Trend Choice

Stretch denim is often misunderstood. It is not about comfort alone. It affects fit tolerance, production yield, and customer feedback.

Non-Stretch Denim (100% Cotton)

Pros:

- Stable fabric structure

- Clear vintage or workwear look

- Easier to control wash appearance

Cons:

- Less forgiving in fit

- Higher return risk for online sales

- Requires very accurate patterns

Stretch Denim (Cotton + Elastane)

Pros:

- Better fit tolerance

- More size flexibility for customers

- Easier for first-time grading

Cons:

- Stretch recovery must be tested

- Washing needs more control

- Lower-quality stretch can lose shape

For first collections, many brands choose low-stretch denim (1–2% elastane). It offers comfort without losing structure. This is not a rule, but it is a common and reasonable starting point.

5. Fabric Shrinkage: One of the Most Common First-Collection Problems

Shrinkage is rarely visible at fabric stage, but it becomes obvious after washing.

From factory experience, common shrinkage-related issues include:

- Jeans becoming shorter after wash

- Waist tightening more than expected

- Inconsistent sizing between colors

Always ask for:

- Fabric shrinkage data (warp and weft)

- Whether the fabric is pre-sanforized

- Wash test results on similar fabric

If shrinkage data is unclear, patterns must include extra allowance. This increases risk for first-time brands.

6. Ring Spun vs Open-End Yarn: What Actually Matters

Yarn type is often mentioned, but it should be understood in simple terms.

- Ring spun yarn: Softer hand feel, more natural texture

- Open-end yarn: More uniform, often lower cost

Ring spun denim is common in premium products, but it may show more wash variation. Open-end denim is more consistent and easier to manage.

For first collections, consistency often matters more than texture. Both options are valid, but expectations should match reality.

7. Fabric Mill Selection Is as Important as Fabric Specs

Two fabrics with the same weight and composition can behave very differently depending on the mill.

Reliable mills usually provide:

- Stable dyeing lots

- Clear technical data

- Repeatable fabric supply

For first collections, avoid fabrics with unclear origin or unstable supply. If reorders are planned, fabric continuity is critical.

Ask your factory:

- Have you worked with this mill before?

- Has this fabric been used in bulk production?

- Is reorder lead time stable?

8. Wash Compatibility: Fabric and Finish Must Match

Not all denim fabrics respond well to all washes.

Examples:

- Soft lightweight denim may distort under heavy stone wash

- High-stretch denim can lose recovery with aggressive enzyme wash

- Dark indigo fabrics may bleed unevenly if dye fixation is weak

When selecting fabric, consider:

- Target wash style (clean, vintage, heavy fade)

- Color consistency requirements

- Whether multiple washes will be used in one collection

It is better to choose a fabric that supports your wash goal than to force a wash effect later.

9. Cost Structure: Fabric Is Only Part of the Total Cost

Fabric cost should be evaluated together with:

- Cutting efficiency

- Sewing time

- Wash yield

- Defect risk

A slightly higher fabric cost may reduce wash rework or size complaints. For first collections, stable cost is often more important than lowest cost.

10. Common Mistakes We See in First Denim Collections

From factory-side experience, these issues appear frequently:

- Choosing fabric based only on hand feel

- Ignoring shrinkage data

- Using complex fabric with limited MOQ

- Selecting fabric without wash testing

- Mixing too many fabric types in one collection

Keeping fabric choices focused helps control production risk.

11. A Practical Starting Point for First-Time Brands

While every brand is different, a common starting setup looks like this:

- 10–12 oz denim

- Low stretch (1–2%) or stable non-stretch

- Pre-sanforized fabric

- Proven mill source

- Wash tested before bulk

This is not a rule, but a practical baseline used by many successful first collections.

12. Final Thoughts From a Manufacturing Perspective

Choosing denim fabric is not about finding the most impressive option. It is about finding the most suitable one for your current stage.

For a first jeans collection:

- Stability is more valuable than complexity

- Predictability is more important than novelty

- Clear communication with your factory reduces risk

As your brand grows, fabric choices can become more specialized. But for the first step, making reasonable, well-tested decisions builds a stronger foundation.

If you treat fabric as a technical partner to your design, not just a visual element, your first collection will be much easier to produce, launch, and repeat.