As a custom denim manufacturing partner with over 12 years on the factory floor, I want to talk about the technical failures that happen before a single yard of fabric is cut.

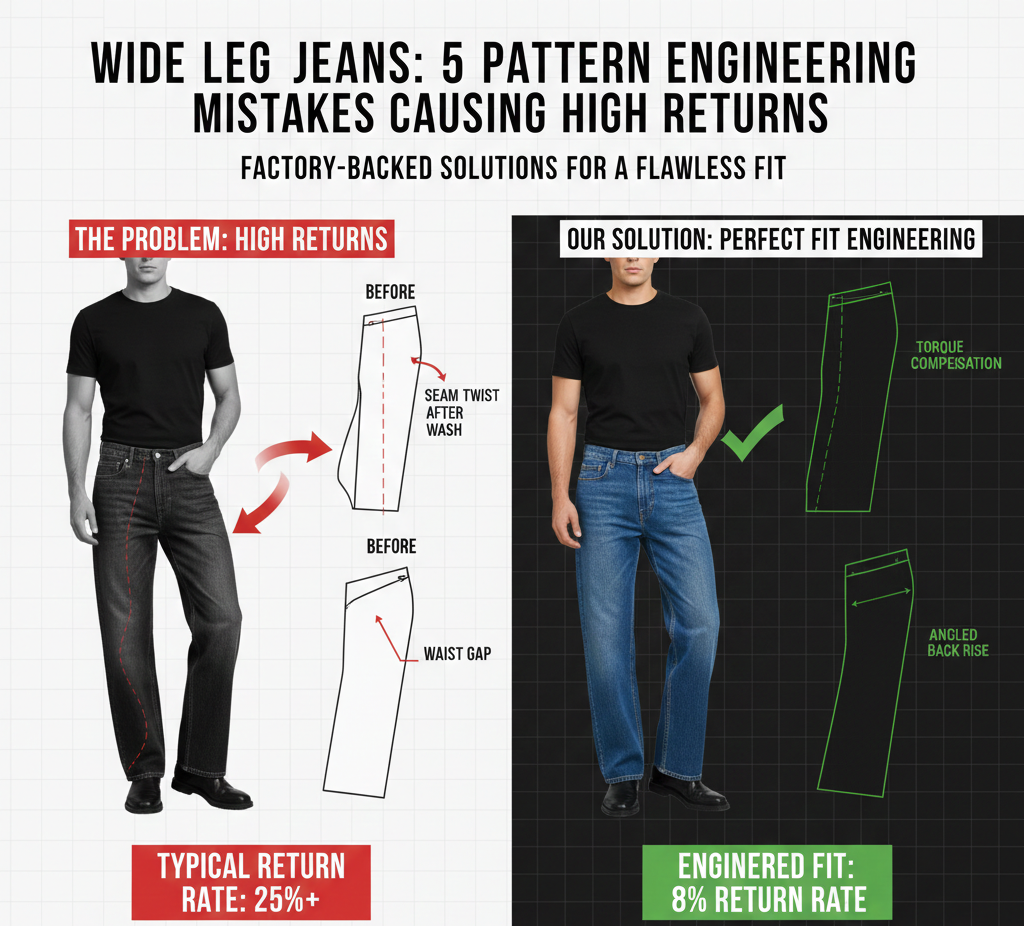

If your wide-leg jeans are hitting return rates of 15% to 20%, you probably don’t have a marketing problem. You have a pattern engineering problem.

The complaints we hear from brands switching to our factory are almost identical: “The leg twists after one wash,” “The waist gaps when I sit,” or “The crotch looks saggy.” These aren’t just “unlucky” fits; they are predictable outcomes of using standard patterns for high-volume silhouettes.

Here are the five most common engineering mistakes we fix at the pattern table to ensure your wide-leg denim stays sold.

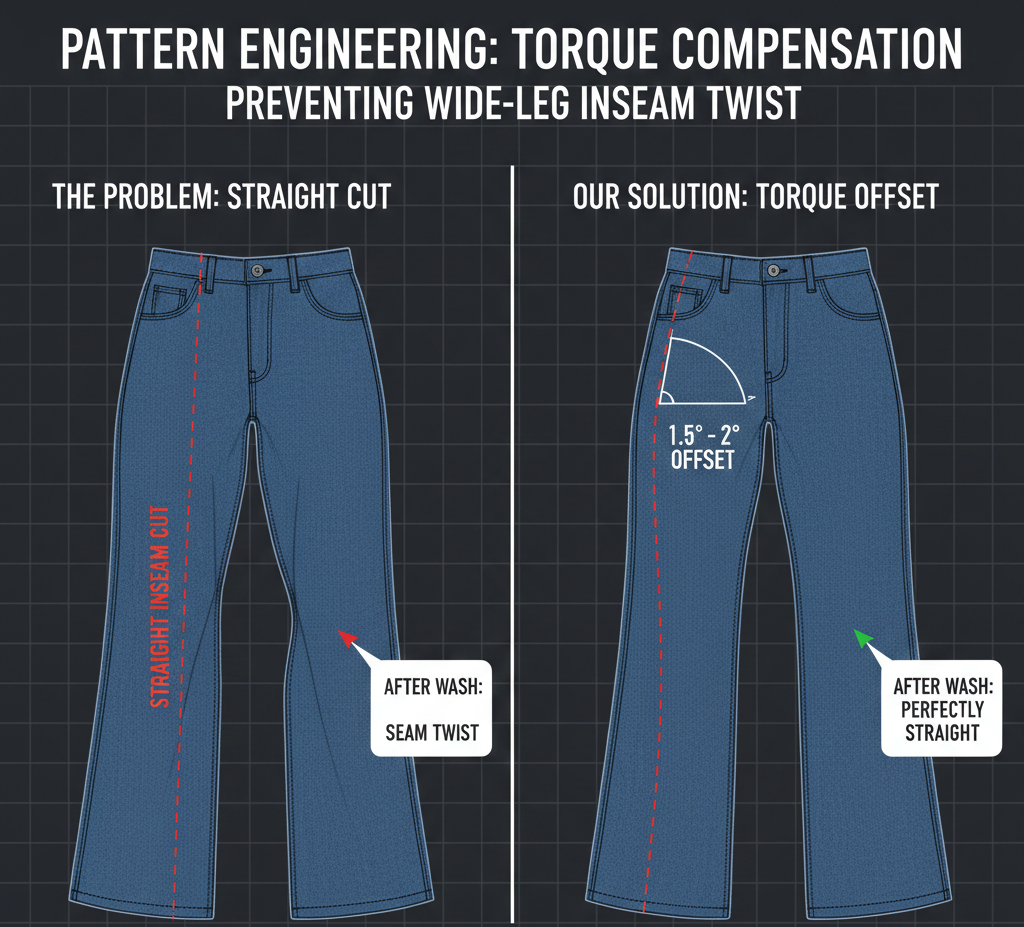

Why Does the Inseam Spiral Around the Leg After Washing?

This is the “silent killer” of wide-leg programs. A customer buys a pair of jeans, they look great in the fitting room, but after one home wash, the inseam starts crawling toward the front of the foot.

The Pattern Mistake

Most factories treat wide-leg patterns as a 2D geometry problem. They cut straight lines. However, denim is a “living” fabric. Because of its twill construction, denim has a natural tendency to torque (twist) in the direction of the weave.

On a slim jean, there isn’t enough fabric for this twist to be noticeable. But on wide-leg jeans, you have 3 to 4 extra inches of fabric. That extra surface area creates massive leverage for the fabric to torque. If the pattern is cut perfectly straight, the fabric will inevitably pull the seam out of alignment during the drying cycle.

Our Solution: Torque Compensation

We don’t cut wide-leg patterns straight. We use Torque Compensation. This means we intentionally offset the pattern by 1.5 to 2 degrees at the knee point.

We essentially “pre-twist” the pattern in the opposite direction of the fabric’s natural torque. When the customer washes the jeans, the fabric pulls the seam back into a perfectly straight vertical line. We validate this by washing every prototype three times in our industrial lab before approving the bulk cut.

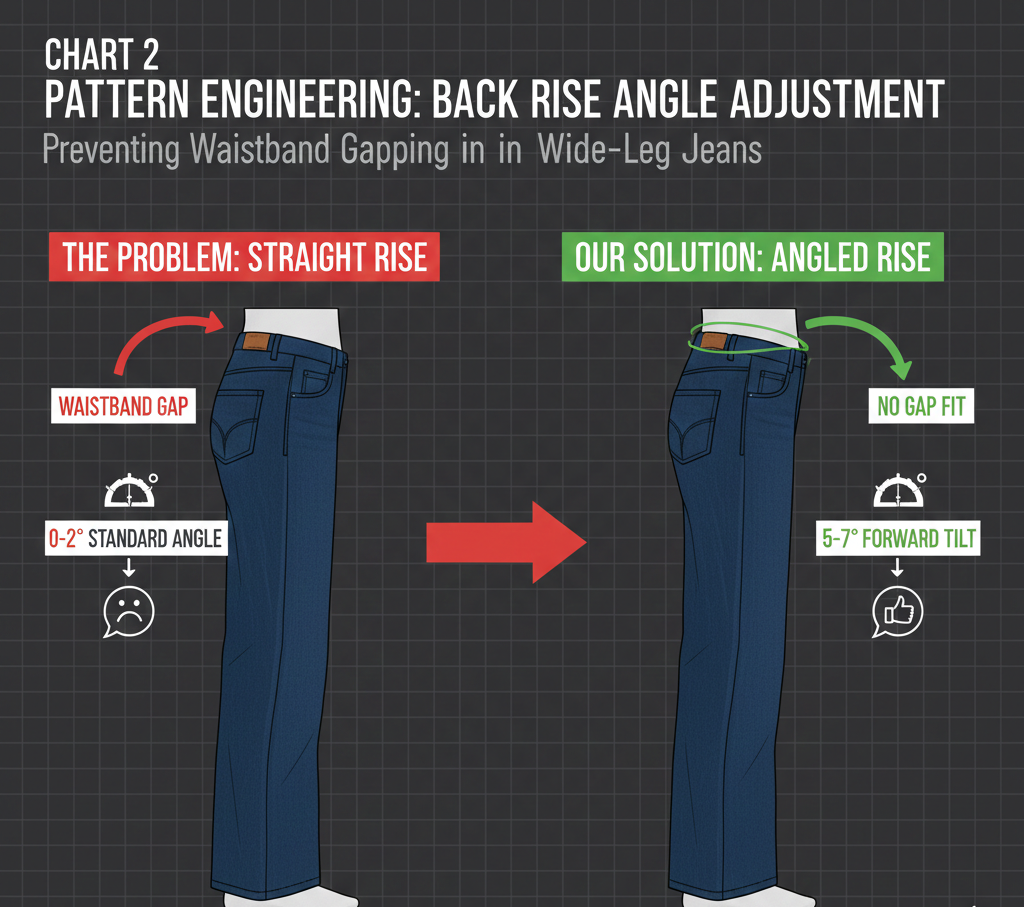

Why Does the Waistband Gap at the Back When Sitting?

There is nothing more frustrating for a customer than a waistband that fits while standing but stands two inches away from the spine the moment they sit down.

The Pattern Mistake

Many manufacturers simply take a straight-leg pattern and add width to the side seams to create a wide-leg look. They ignore the “top block” (the area from the waist to the hip).

Wide-leg jeans have significantly more weight and volume in the lower leg. When a wearer sits, that extra fabric pulls downward. If the back rise angle is too vertical—as it often is in standard fits—the waistband has no choice but to pull away from the body.

Our Solution: Back Rise Angle Adjustment

In our custom denim manufacturing process, we rebuild the top block specifically for volume. For wide-leg fits, we increase the back rise angle by 5 to 7 degrees. This forward tilt acts as an anchor.

We also deepen the curve of the back yoke. This ensures that even when the heavy leg fabric pulls down during movement, the waistband stays “locked” against the lower back. We test this on live fit models with a “sit-and-reach” test; if the gap is more than 0.5 inches, the pattern goes back for adjustment.

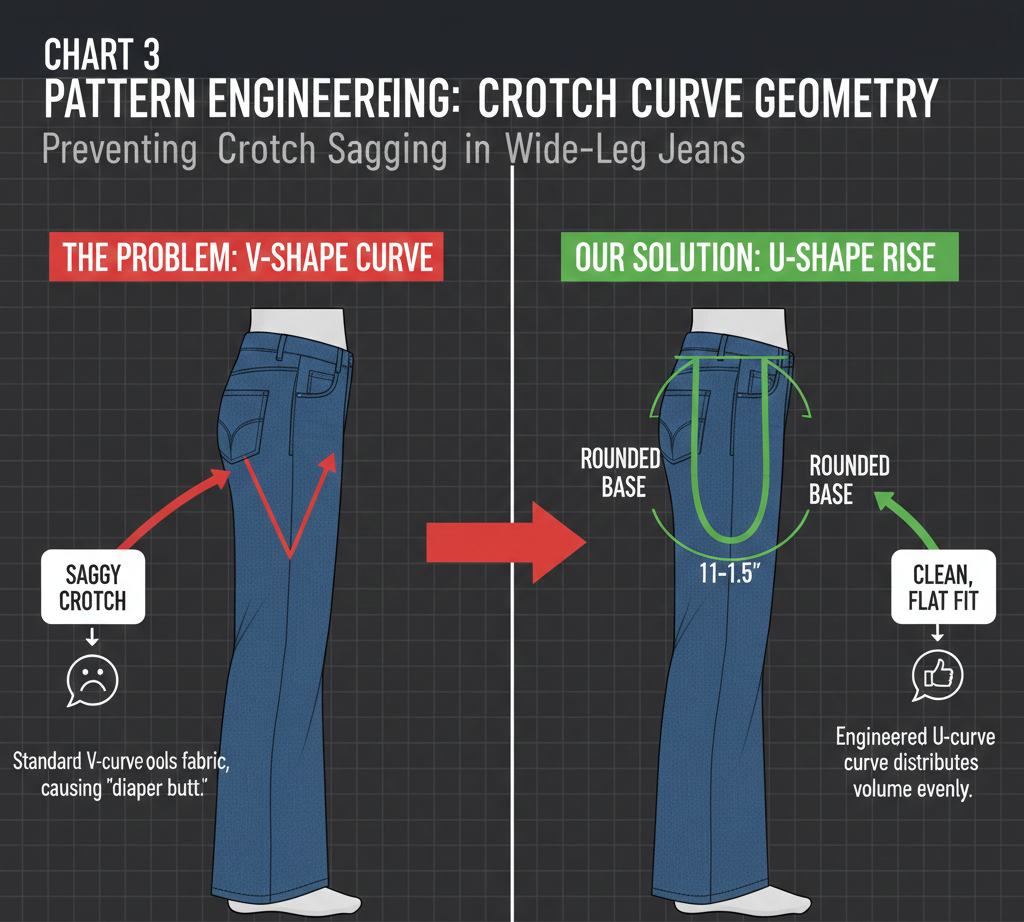

Why Do Wide-Leg Jeans Sag at the Crotch?

Customers often call this “diaper crotch.” It’s that unflattering pool of excess fabric hanging between the thighs. It makes a premium wide-leg jean look like a cheap, ill-fitting garment.

The Pattern Mistake

The culprit is almost always a “V-shaped” crotch curve. V-curves are narrow and pointed, designed for slim jeans where the fabric stays close to the body. When you try to attach a wide, voluminous leg to a narrow V-curve, the extra fabric has nowhere to go. It collapses and pools at the lowest point.

Our Solution: U-Shaped Crotch Engineering

For wide-leg styles, our denim factory engineers use a deep, wide U-shaped curve.

By widening the base of the crotch seam and increasing the curve depth by roughly 1 to 1.5 inches, we allow the leg fabric to hang naturally from the hip. This eliminates the “pooling” effect. The result is a clean, flat front that preserves the “loose” aesthetic without the “baggy” mess.

Why Does One Leg Look Shorter Than the Other After Production?

This is a nightmare for quality control. You measure the jeans at the factory, and they are identical. The customer washes them, and suddenly the left leg is an inch shorter than the right.

The Pattern Mistake: Grain Alignment

Because wide-leg panels are so large, they take up a lot of room on a fabric roll. To save on material costs, some factories “nest” the patterns too tightly, sometimes rotating a leg piece slightly to make it fit.

If a leg is cut even a few degrees off the vertical grain of the denim, it will shrink at a different rate than the other leg. Since wide-leg jeans have more surface area, these small percentage differences in shrinkage result in very visible length discrepancies.

Our Solution: Strict Grain Integrity

In our cutting room, we prioritize Grain Alignment over fabric savings. We enforce a minimum 2cm buffer between all leg panels and ensure both legs are oriented in the exact same direction on the fabric.

We would rather lose a small percentage of fabric than lose a customer to a “short leg” return. Our QC team checks the thread direction on every batch to ensure the warp and weft are perfectly aligned before the first stitch is sewn.

Why Do Wide-Leg Jeans Fit Inconsistently Across Sizes?

A common problem: the size 32 fits perfectly, but the size 28 looks like a parachute and the size 38 looks like a standard straight fit.

The Pattern Mistake: Linear Grading

Most factories use “linear grading”—they add or subtract the same amount of fabric at every size. But body proportions don’t scale linearly, especially in wide-leg silhouettes. A smaller frame can easily be “swallowed” by too much leg volume, while a larger frame needs more than just a wider waist to maintain the “wide” look.

Our Solution: Proportional Grading Logic

As a professional men’s jeans factory, we use Proportional Grading.

- Small Sizes (28-30): We slightly reduce the leg opening ratio so the volume doesn’t overwhelm the wearer.

- Large Sizes (36-40): We increase the thigh ease and leg opening more aggressively to ensure the “wide-leg” aesthetic is preserved.

This ensures that the “vibe” of the jean remains the same, whether the customer is a size 28 or a 40.

Technical Questions to Ask Your Denim Manufacturer

If you are looking for a custom denim manufacturing partner, the quality of their answers to these questions will tell you if they truly understand wide-leg engineering:

- “How do you compensate for fabric torque in a wide-leg pattern?” (If they don’t mention an offset or compensation, expect twisted legs.)

- “Do you use a V-curve or a U-curve for your wide-leg crotch engineering?” (U-curve is the only correct answer for this silhouette.)

- “What is your grain alignment tolerance during the cutting process?” (Professional factories should have a strict “no-rotation” policy for leg panels.)

- “Do you use linear or proportional grading for your size runs?” (Proportional grading is essential for consistent fit across the board.)

Our Manufacturing Standards and Timelines

We specialize in high-precision, custom denim manufacturing for brands that cannot afford high return rates. We understand that in the B2B world, a “cheap” jean that gets returned is actually the most expensive product you can sell.

We offer a streamlined production process designed for reliability:

- Sample Development: 7 – 10 days (including full fit testing).

- Minimum Order Quantity (MOQ): 200 pieces per style.

- 200 – 1,000 Pieces: 15 days lead time.

- 1,000 – 5,000 Pieces: 20 days lead time.

- 5,000 – 10,000+ Pieces: 20 – 30 days lead time.

Summary: Engineering Confidence into Every Pair

Wide-leg jeans are more than just “straight jeans with more fabric.” They are a 3D engineering challenge. By focusing on torque compensation, rise angles, crotch geometry, grain alignment, and proportional grading, we help brands reduce their returns and build customer loyalty.

When you work with a specialized denim factory, you aren’t just paying for sewing; you are paying for the technical expertise that keeps your inventory moving forward, not coming back in return boxes.

Are you ready to fix your fit issues? We are happy to provide a technical review of your current tech packs. Contact us today to see how our custom denim manufacturing expertise can stabilize your wide-leg program and lower your return rates.