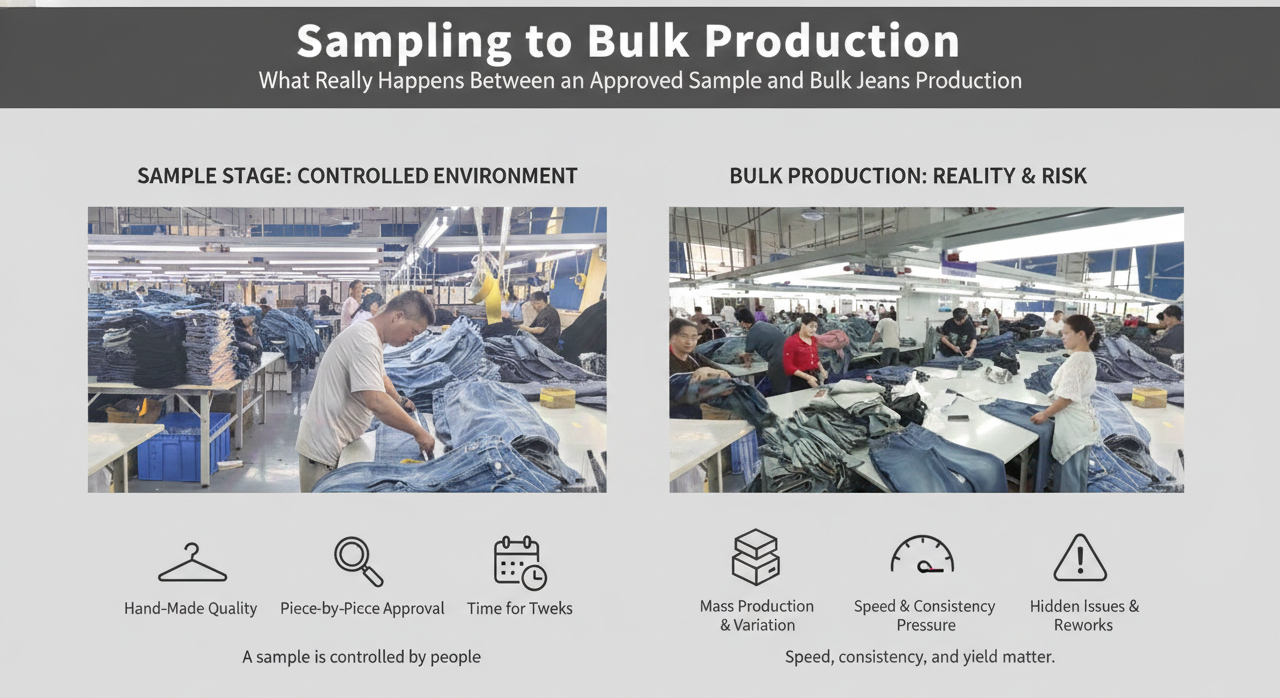

What Really Happens Between an Approved Sample and Bulk Jeans Production

In custom denim manufacturing, most problems do not start in bulk production.

They start in the gap between an approved sample and the first bulk run.

From the factory side, this is the most sensitive stage.

From the brand side, this is also where expectations often break.

Many brands assume that once a sample is approved, bulk production is simply a repeat.

In reality, sampling and bulk production are two very different systems, with different pressures, timelines, and risks.

Understanding how this transition works helps brands avoid delays, quality disputes, and cost surprises.

Why does bulk production sometimes look different from the approved sample?

This is one of the most common questions brands ask after receiving bulk goods.

The short answer is:

a sample is controlled by people, while bulk production is controlled by systems.

During sampling:

- One or two skilled operators handle the garment

- Sewing speed is slow and careful

- Fabric usage is flexible

- Adjustments are made piece by piece

During bulk production:

- Dozens of operators work in sequence

- Speed, consistency, and yield matter

- Fabric is cut in layers, not individually

- Every small change affects hundreds or thousands of units

If details are not fully standardized during sampling, differences will appear in bulk.

What is the real purpose of the sampling stage?

Sampling is not just about making a “nice-looking” jean.

Its real purpose is to lock down variables before production scales.

This includes:

- Pattern logic and grading rules

- Fabric behavior after washing

- Stitch tension and seam balance

- Measurement tolerance ranges

- Wash results at scale, not just on one piece

A sample that looks good but is not production-ready creates risk later.

How many sample rounds are usually needed before bulk?

There is no fixed number, but in real factory work, most projects follow this pattern:

- 1st sample: structure and fit validation

- 2nd sample: fabric, wash, and measurement adjustment

- 3rd sample (or size set): confirmation for bulk

For simple styles, two rounds may be enough.

For stretch denim, plus size jeans, or complex washes, three rounds are common.

Skipping sample rounds usually saves time short term, but creates delays later.

What details must be fully confirmed before bulk production?

Before bulk starts, several items must be clearly approved in writing.

Pattern and grading

- Final pattern version

- Size grading logic

- Key fit reference points (waist, hip, thigh, rise)

If grading rules are not locked, bulk measurements will drift.

Fabric and trims

- Exact fabric lot or specification

- Stretch ratio and recovery

- Pocketing, zipper, button, thread type

Changing fabric after sampling almost always affects fit and wash results.

Washing and finishing

- Wash recipe

- Enzyme, stone, or chemical process

- Target shade range and hand feel

A wash that works on one sample may behave differently on 500 pieces.

Measurement tolerance

- Acceptable variance range

- Critical measurement points

Bulk production works with tolerance, not perfection.

Why does stretch denim increase risk between sample and bulk?

Stretch denim adds flexibility, but also uncertainty.

During sampling, stretch fabric is often cut single-layer and sewn slowly.

In bulk, fabric is cut in layers, under pressure, and sewn faster.

This can lead to:

- Waist growth after wash

- Inconsistent recovery

- Leg twist or shape change

That is why stretch denim projects often require:

- Extra wash testing

- Pre-production samples

- Clear shrinkage and stretch data

Ignoring this step is one of the biggest causes of bulk complaints.

What is a pre-production sample, and when is it needed?

A pre-production sample (PP sample) is made using:

- Bulk fabric

- Bulk trims

- Bulk wash method

- Production-line workflow

It acts as a final checkpoint before mass cutting begins.

PP samples are strongly recommended when:

- Order quantity is large

- Wash process is complex

- Fabric is stretch or lightweight

- Brand is producing the style for the first time

Skipping PP samples increases speed, but also risk.

How does cutting for bulk differ from sampling?

In sampling, fabric is cut carefully, often one piece at a time.

In bulk production:

- Fabric is spread in layers

- Cutting pressure is higher

- Small alignment errors multiply

If fabric relaxation time is ignored before cutting, measurements can shift after wash.

This is especially important for:

- High-stretch denim

- Lightweight fabrics

- Large size ranges

Proper cutting control protects fit consistency.

What happens on the sewing line during bulk production?

Bulk sewing is a sequence of operations, not one person making one jean.

Each operator handles one step:

- Pocket setting

- Fly construction

- Inseam or outseam

- Waistband attachment

If stitch tension or machine settings differ from the sample stage, visual and structural differences appear.

That is why factories create:

- Sewing operation sheets

- Machine setting references

- Sample reference boards on the line

Consistency is built through process, not memory.

How are measurements controlled during bulk production?

In bulk, not every piece is measured.

Instead, factories rely on:

- In-line checks

- Random sampling

- Measurement tolerance rules

Critical points such as waist, hip, and inseam are monitored more closely.

If measurement drift is found early, adjustments can be made.

If found late, rework or rejection becomes costly.

Clear measurement standards reduce disputes later.

What quality checks happen before finishing and packing?

Before jeans are washed and packed, several checks usually occur:

- Visual inspection for sewing defects

- Measurement spot checks

- Trim and label verification

After washing:

- Shade consistency check

- Hand feel and shrinkage review

- Final measurement confirmation

Each stage filters risk before shipment.

Why do brands experience issues even after sample approval?

Most disputes do not come from mistakes.

They come from assumptions.

Common assumptions include:

- “Bulk will look exactly like the sample”

- “Small changes won’t matter”

- “The factory will adjust automatically”

In reality, factories follow confirmed specs.

Anything not clearly defined becomes a variable.

Clear communication protects both sides.

How can brands reduce risk between sampling and bulk?

From a factory perspective, smooth transitions happen when brands:

- Take sampling seriously, not just visually

- Confirm specs in writing

- Allow time for PP samples

- Understand tolerance, not perfection

Bulk production rewards preparation more than speed.

Why understanding this stage matters for sourcing decisions

Sampling to bulk production is where experience shows.

Factories that manage this stage well:

- Ask detailed questions early

- Explain risks instead of hiding them

- Push back when specs are unclear

- Document changes carefully

For brands, this stage often determines whether a factory becomes a long-term partner or a one-time supplier.

Related pages you may find helpful

To understand how this stage connects with the full workflow, you may also review:

- Custom Jeans Manufacturing Process

- Quality Control in Denim Production

- Common Production Mistakes Brands Make

Each page focuses on a different risk point in denim manufacturing.