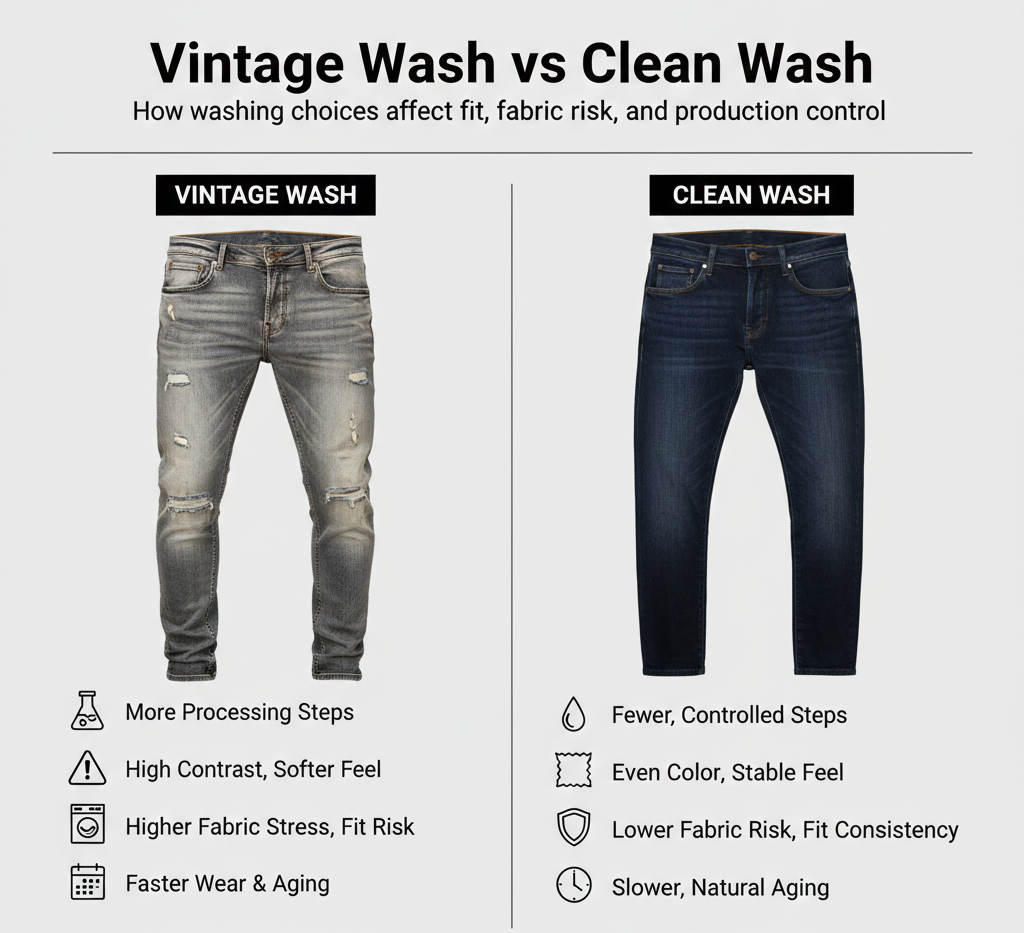

How washing choices affect fit, fabric risk, and production control

When brands plan a denim collection, wash style is often discussed late in the process.

Many teams focus first on fit, fabric, and price, and treat washing as a visual finish.

In real manufacturing, washing is not just about look.

It affects fabric behavior, fit stability, rejection rate, and long-term product performance.

Two of the most common directions — vintage wash and clean wash — lead to very different production paths.

What is considered a vintage wash in denim production?

Vintage wash is not one single technique.

In factories, it usually refers to washes designed to create a worn, aged, or broken-in look.

Common characteristics include:

- Faded color

- High contrast

- Visible texture changes

- Soft hand feel

Typical processes may involve:

- Enzyme washing

- Stone washing

- Abrasion or mechanical action

- Multiple wash steps

The key point is that vintage wash actively changes the fabric surface and structure.

What defines a clean wash?

Clean wash focuses on keeping the denim appearance controlled and minimal.

It usually aims for:

- Even color tone

- Clear fabric texture

- Stable shape

- Minimal surface damage

Clean wash programs are often:

- Shorter

- Lower in mechanical stress

- More controlled in temperature

- Less aggressive on fabric

From a production view, clean wash is about preserving what the fabric already is, not forcing change.

Visual difference is obvious — production difference is not

From the outside, the difference seems simple:

- Vintage wash looks more worn

- Clean wash looks more new

Inside the factory, the difference is much bigger.

Vintage wash:

- Requires more steps

- Has more variables

- Needs closer monitoring

Clean wash:

- Is simpler to repeat

- Has fewer risk points

- Is easier to standardize

This difference becomes very clear in bulk production.

How vintage wash affects fabric behavior

Vintage washing puts fabric under stress.

During the process:

- Fibers are weakened

- Yarn surfaces are broken

- Fabric density can change

This is why vintage-washed jeans often feel softer — but softness comes from controlled damage, not softness added for free.

In rigid denim, this can be acceptable and even desired.

In stretch denim, this becomes a major risk factor.

How clean wash preserves fabric stability

Clean wash keeps most of the fabric’s original structure intact.

Because the process is milder:

- Shrinkage is more predictable

- Recovery loss is lower

- Fabric strength remains higher

For brands that care about long-term wear, clean wash offers better control.

This does not mean clean wash is “better” — it means it is more stable.

Fit consistency: where the real difference shows

Fit issues are one of the biggest cost drivers for denim brands.

Vintage wash and fit risk

Vintage wash can change:

- Garment length

- Leg shape

- Waist tension

- Overall balance

Because fabric is softened and loosened, small pattern tolerances can turn into visible fit problems.

Factories often need to:

- Adjust patterns specifically for vintage wash

- Add shrinkage allowance

- Accept higher rejection rates

Clean wash and fit stability

Clean wash maintains the relationship between pattern and fabric.

As a result:

- Size grading stays consistent

- Measurement deviation is smaller

- Fit complaints are easier to manage

For new brands or first collections, this stability is often underestimated.

Stretch denim: vintage wash vs clean wash

This is where the decision becomes critical.

Vintage wash + stretch denim:

- Higher elastane damage risk

- Recovery loss after wear

- Increased return rates

Clean wash + stretch denim:

- Better recovery retention

- More predictable fit

- Longer product life

Many factories will strongly advise against heavy vintage washes on high-stretch fabrics unless the brand accepts the trade-off.

Durability and wear lifecycle

Vintage wash jeans often feel great on first wear.

But their lifecycle can be shorter.

Common long-term effects:

- Faster thinning at stress points

- Earlier fabric failure

- Reduced resale or archive value

Clean wash jeans:

- Age more slowly

- Develop wear naturally over time

- Maintain structure longer

Brands aiming for longevity or premium positioning often lean toward cleaner washes.

Cost and production control differences

Vintage wash costs more than many brands expect.

Cost drivers include:

- Longer machine time

- Higher water and chemical use

- More labor monitoring

- Higher rejection risk

Clean wash:

- Is easier to scale

- Has more predictable cost

- Allows tighter production planning

The cost gap increases in small runs or low MOQ projects.

MOQ and scalability considerations

For low MOQ or test collections:

- Clean wash is easier to manage

- Vintage wash may require minimum batch sizes

For large volumes:

- Vintage wash requires strong process control

- Clean wash scales more smoothly

Factories often recommend starting clean, then adding vintage styles once volume and data increase.

Brand positioning and customer expectation

Wash choice should match how the customer uses the product.

Vintage wash fits brands that:

- Focus on streetwear

- Emphasize character and individuality

- Accept variation as part of the look

Clean wash fits brands that:

- Value fit accuracy

- Want consistent repeat orders

- Sell through e-commerce with return sensitivity

Neither is right or wrong — mismatch is the real problem.

Common mistakes brands make when choosing wash style

From the factory side, common issues include:

- Choosing vintage wash without adjusting pattern

- Using the same wash for stretch and rigid denim

- Approving samples without bulk wash testing

- Underestimating wash impact on fit

- Treating wash as only a visual choice

Most washing problems start before production, not during it.

How factories usually guide wash decisions

Experienced factories look at:

- Fabric type

- Stretch level

- Fit tolerance

- Target customer

- Volume expectations

Wash is then selected to support the product, not dominate it.

When wash and fabric fight each other, quality suffers.

How this page fits into your washing strategy

This comparison works best when read alongside:

- Denim washing methods explained

- Stretch denim washing risks

- How washing changes fit

Together, these pages help brands move from visual thinking to production thinking.

Final perspective from production

Vintage wash creates character.

Clean wash creates control.

In denim manufacturing, the right wash is not about which looks better in photos —

it is about which one survives production, delivery, and real wear.

Brands that understand this early avoid many costly corrections later.