How Fabric Choice Really Affects Fit, Production, and Long-Term Wear

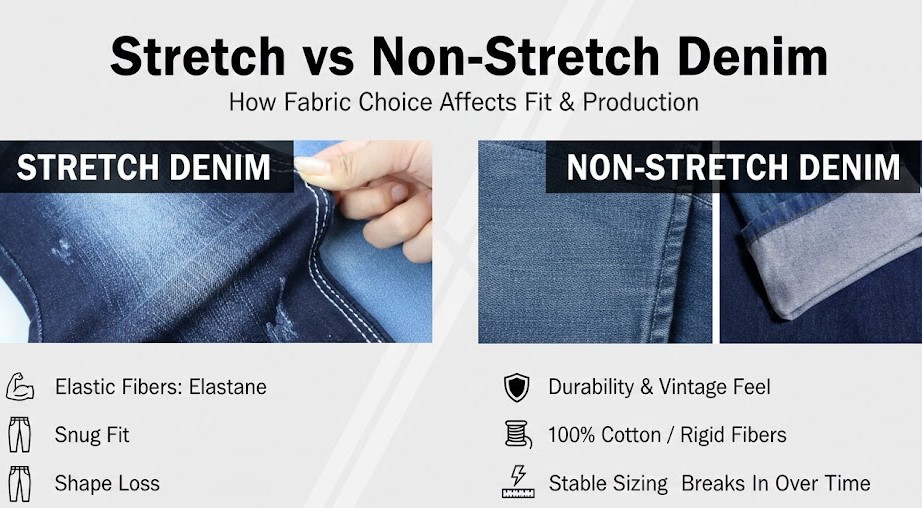

When brands start sourcing denim, one of the first decisions they face is whether to use stretch denim or non-stretch denim.

On paper, the difference seems obvious.

Stretch is associated with comfort.

Non-stretch is linked to durability and a vintage look.

In actual production, however, this choice reaches much further. It affects how a pattern behaves in bulk, how stable sizing remains after washing, how fabric performs after repeated wear, and how many fit-related issues appear after launch.

Most of the problems factories are asked to fix later — baggy knees, loose waistbands, unstable sizing — can often be traced back to this early fabric decision rather than sewing quality or workmanship.

What follows is not a trend comparison. It reflects what typically happens once a fabric moves from sampling into bulk production and then into real customer use.

What Stretch Denim Really Means in Production

Stretch denim is denim fabric that includes elastic fibers, allowing the fabric to extend and recover during wear.

In most cases, the elasticity comes from elastane blended into the weft yarn.

Common stretch denim compositions include:

- 98% cotton / 2% elastane

- 97% cotton / 3% elastane

- Cotton blended with polyester and elastane for higher recovery

From the outside, these fabrics may look similar. In production, they behave very differently.

Stretch can be engineered in several ways:

- Weft stretch, the most common option

- Warp stretch, less common and higher cost

- Bi-stretch, used only in niche applications

In factory terms, stretch denim is not a single fabric type. It functions more like a system. Yarn quality, elastane grade, weaving tension, and finishing all influence how the fabric performs after washing and repeated wear.

Two fabrics labeled “2% elastane” can deliver completely different results once they enter bulk production.

How Non-Stretch Denim Behaves on the Line

Non-stretch denim contains no elastane or elastic fibers.

It is traditionally made from:

- 100% cotton

- Cotton blends using rigid fibers, such as recycled cotton

This is the fabric most people associate with vintage jeans, workwear, raw denim, and heritage reproductions.

Without elasticity, non-stretch denim relies entirely on pattern engineering, fabric weight, and weave structure to create fit and comfort.

From a manufacturing standpoint, rigid denim is less forgiving. Small pattern errors show up quickly. At the same time, once the fabric is properly controlled, its behavior is more predictable across production runs.

Fiber Composition and Construction: Where Differences Start

Stretch Denim: What Factories Pay Attention To

Brands often focus on elastane percentage. Factories focus on how that elastane behaves.

Key variables include:

- Elastane brand and grade

- Core-spun yarn quality

- Elastane tension during weaving

- Recovery rate after washing

Recovery matters more than stretch amount. Fabric that stretches easily but fails to recover leads to sagging knees, loose seats, and unstable waistlines.

In bulk production, poor recovery is one of the most common causes of customer complaints and returns.

Non-Stretch Denim: Fewer Variables, Less Margin for Error

Rigid denim does not stretch to hide mistakes.

Factories monitor:

- Yarn count consistency

- Ring-spun versus open-end yarn

- Weave density

- Sanforization level

Once these factors are controlled, non-stretch denim tends to remain dimensionally stable throughout production.

Sampling Versus Bulk: Where Expectations Break

This is where many first-time brands run into trouble.

Stretch Denim During Sampling

At the sample stage, stretch denim often performs well:

- Fits comfortably

- Feels forgiving

- Appears flattering on different body types

This can create confidence early on.

During bulk production, new variables enter the process. Fabric batches may behave slightly differently. Washing heat may affect elastane recovery. Sewing tension can over-stretch areas like the waistband or hip.

The result is often subtle size drift rather than obvious defects.

Non-Stretch Denim Across Production

In sampling, rigid denim can feel stiff. Buyers sometimes worry about comfort.

Once bulk production begins, however, the fit usually stays consistent. Grading remains stable. Post-wash measurements are easier to control.

When size communication is clear, return rates tend to be lower.

Comfort and Shape Retention Over Time

Comfort and structure are not opposites. They exist on a curve.

Stretch Denim Over Time

Stretch denim offers easier wear from day one, especially for fitted silhouettes.

Its long-term performance depends on recovery.

If recovery weakens, shape loss becomes noticeable after repeated wear. Comfort remains, but the garment no longer holds its intended form.

Non-Stretch Denim Over Time

Rigid denim often feels stiff at first. Comfort develops as the fabric breaks in.

Once broken in, the silhouette remains stable. Many customers prefer this aging process, especially in classic or heritage styles.

For many brands, a low-stretch option around 1–1.5% elastane offers a balance between comfort and structure.

Washing, Shrinkage, and Recovery Control

Stretch Denim in Washing

Stretch denim is sensitive to heat and mechanical stress.

Elastane degradation can occur during aggressive washing programs.

A common mistake is applying heavy vintage washes to stretch denim. This often leads to permanent deformation and loss of recovery.

Non-Stretch Denim in Washing

Non-stretch denim handles heavy washes more predictably, especially when sanforized.

It is generally preferred for distressed, vintage, and high-contrast wash effects.

For complex washing programs, factories often recommend non-stretch fabrics to reduce risk.

Durability and Wear Lifecycle

After-sales data tends to show different patterns.

Stretch denim offers early comfort but may have a shorter lifespan if recovery weakens.

Non-stretch denim ages more consistently. Its wear patterns are often considered part of the product’s character, especially for premium or heritage-focused brands.

This difference matters when brands think about sustainability positioning, resale value, and long-term customer satisfaction.

Cost Structure and MOQ Considerations

Stretch Denim Cost Factors

Costs are influenced by:

- Elastane yarn pricing

- Branded elastane premiums

- Higher testing and quality control needs

Fabric control requirements may increase minimum order quantities, especially when dye lot consistency is critical.

Non-Stretch Denim Cost Factors

Costs depend more on yarn quality and fabric weight.

Processing is simpler, and fabric substitutions are often easier if supply changes.

Lower risk can allow more flexibility during development.

Matching Fabric Choice to Brand Type

Different brands prioritize different outcomes.

- Women’s fashion denim often benefits from controlled stretch

- Men’s classic denim works well with non-stretch or minimal stretch

- Streetwear and baggy fits typically use non-stretch

- Sculpted silhouettes rely on high-recovery stretch

- Vintage and heritage styles favor rigid denim

- Plus-size denim requires engineered stretch rather than higher percentages

Common Sourcing Mistakes Seen in Factories

Some issues appear repeatedly:

- Choosing elastane percentage without recovery testing

- Using the same pattern for stretch and non-stretch fabrics

- Ignoring wash impact on elastane

- Underestimating fabric variation in bulk

- Assuming stretch automatically solves fit problems

Most fit complaints begin with fabric decisions rather than sewing errors.

Making the Decision More Practical

Instead of asking which fabric is trending, it helps to ask different questions:

- Does the silhouette depend more on comfort or structure?

- Will the wash program affect elastane recovery?

- Can customers accept a break-in period?

- Are returns more costly than fabric upgrades?

- Is bulk fabric testing under control?

When uncertainty remains, many brands start with low-stretch denim or develop two fabric options during sampling.

Questions Brands Often Ask

Is stretch denim always better for women’s jeans?

Not necessarily. Many fit issues come from poor recovery rather than lack of stretch.

Does non-stretch denim mean uncomfortable?

Only when pattern and grading are poorly developed.

Can fabric be changed after sampling?

Yes, but pattern adjustments are required.

Which fabric causes fewer surprises in bulk?

Properly sanforized non-stretch denim tends to be more predictable.

Final Thoughts from Production

The choice between stretch and non-stretch denim is less about style and more about system stability.

Brands that perform well long term focus on how fabric behaves after sampling, during bulk production, and through repeated wear — not just how it feels on the first fitting.

Fabric decisions made early tend to shape everything that follows.

Related Reading

- Denim Fabric Types Explained

- How Denim Stretch Recovery Is Tested

- How Washing Changes Denim Fit

- Choosing Denim for Plus-Size Jeans

- MOQ Planning for Custom Denim Production