Denim Fabric Options for Jeans Manufacturing

Fabric choice is one of the most important decisions in denim manufacturing. It affects not only the look and feel of the jeans, but also fit behavior, washing results, durability, and production consistency.

From a factory perspective, denim fabric selection is never only about trends or appearance. It is a balance between design intent, wear performance, production feasibility, and long-term stability in bulk manufacturing.

Below is an overview of the denim fabric options we commonly work with during jeans development and production, explained from a practical manufacturing standpoint.

Cotton Denim Overview

Cotton denim remains the foundation of most jeans production. Its popularity is not only due to tradition, but also because of its versatility, durability, and adaptability to different washing and finishing methods.

In manufacturing, cotton denim is evaluated based on several key factors: fiber quality, yarn type, weave structure, and fabric stability. These elements influence how the fabric behaves during cutting, sewing, washing, and final wear.

Most cotton denim used in jeans is woven in a twill structure, which provides strength while allowing the fabric to soften over time. Depending on the yarn and finishing, cotton denim can feel rigid and structured or relatively soft even before washing.

From a production point of view, cotton denim offers predictable behavior. It holds shape well, responds consistently to standard wash processes, and allows for accurate pattern control. This makes it suitable for a wide range of styles, from classic straight-leg jeans to modern wide-leg or relaxed fits.

However, pure cotton denim also has limitations. Without stretch, it may feel restrictive in certain fits, especially in slim or body-hugging styles. Fabric shrinkage and post-wash measurement changes must also be carefully controlled during development.

Stretch Denim Options

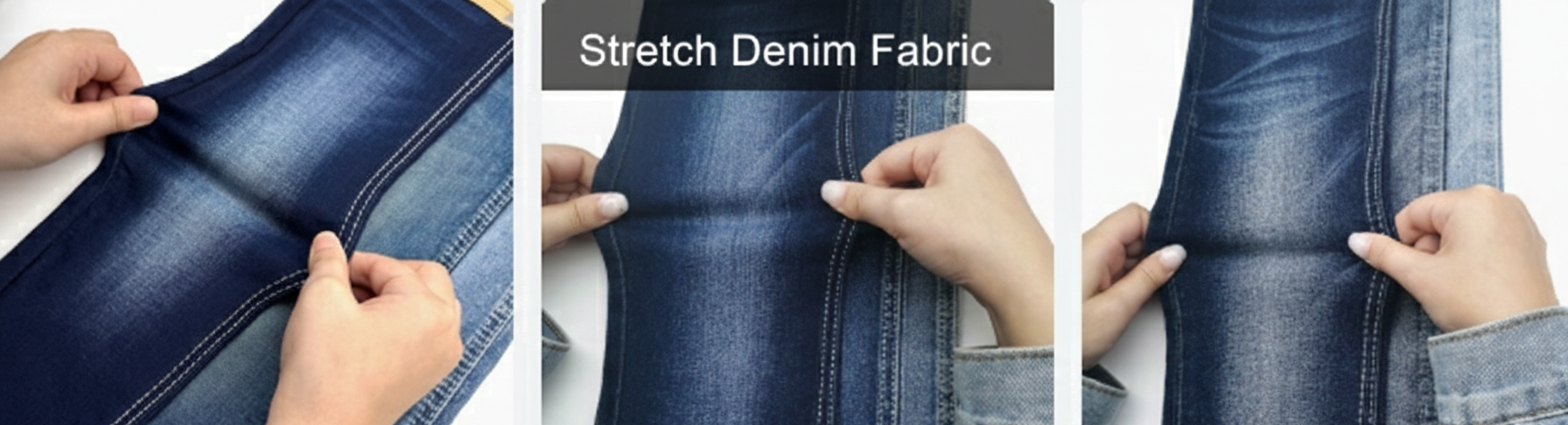

Stretch denim is widely used in modern jeans, especially for styles that require comfort, flexibility, or a closer fit. In production, stretch denim is usually created by blending cotton with elastic fibers such as elastane or similar materials.

From a manufacturing perspective, stretch denim introduces additional variables that must be managed carefully. While stretch improves comfort and mobility, it also affects pattern making, sewing tension, and wash control.

Different stretch levels serve different purposes. Low-stretch denim provides subtle flexibility while maintaining a structured appearance. Medium to higher stretch levels are often used in skinny fits, women’s jeans, and styles designed for daily comfort.

One important consideration is stretch recovery. A fabric may stretch easily, but poor recovery can lead to bagging at the knees or seat after wear. During fabric selection, we assess both stretch percentage and recovery performance to ensure the jeans maintain their shape over time.

Stretch denim also reacts differently during washing. Excessive heat, aggressive washing, or improper drying can damage elastic fibers and reduce performance. For this reason, stretch denim requires controlled washing processes and clear communication between fabric selection and finishing stages.

Non-Stretch Denim Options

Non-stretch denim, often referred to as rigid denim, is made without elastic fibers. It is commonly used for classic jeans, vintage-inspired styles, and products where structure and long-term durability are priorities.

From a factory standpoint, non-stretch denim offers stability and consistency. The fabric is easier to control during cutting and sewing, and measurement accuracy is more predictable after washing, provided proper shrinkage allowances are built into the pattern.

Non-stretch denim is often chosen for men’s jeans, straight or loose fits, and styles where a firm hand feel is desired. It also performs well in heavy washing techniques, such as stone wash or vintage effects, where stretch fibers might be at risk.

That said, non-stretch denim requires careful fit development. Since there is no flexibility in the fabric, pattern accuracy becomes more critical. Small changes in measurement or grading can significantly affect comfort.

For brands considering non-stretch denim, we usually recommend additional fitting rounds during sampling to ensure the final product meets wear expectations.

Denim Weights & Constructions

Denim weight and construction play a major role in how jeans feel, wear, and age over time. Fabric weight is typically measured in ounces per square yard, and each range serves different design and functional purposes.

Lightweight denim is often used for summer styles, relaxed fits, or fashion-forward designs. It offers breathability and softness but may require reinforcement in stress areas to maintain durability.

Mid-weight denim is the most commonly used range in jeans manufacturing. It provides a balance between comfort and strength, making it suitable for everyday wear across many styles and markets.

Heavyweight denim is chosen for structured silhouettes, workwear-inspired designs, or premium rigid jeans. It offers durability and a distinct hand feel but may require more time to break in for the end user.

Beyond weight, construction details such as yarn count, weaving density, and selvedge versus non-selvedge construction also influence fabric behavior. These factors affect how the denim reacts during washing, how it drapes on the body, and how it ages with wear.

From a production perspective, matching fabric weight and construction to the intended design is essential. An unsuitable combination can lead to sewing difficulties, unexpected shrinkage, or inconsistent wash results.

Sustainable Denim Fabric Options

Sustainable denim fabrics are increasingly requested by brands, but their use must be evaluated carefully within real production conditions.

In manufacturing, sustainable denim often refers to fabrics made with organic cotton, recycled fibers, or processes designed to reduce environmental impact. Availability, consistency, and performance are key considerations when working with these materials.

Not all sustainable denim fabrics behave the same as conventional denim. Some recycled or blended fabrics may have different strength, stretch, or washing responses. For this reason, testing during sampling is especially important.

We work with sustainable denim options when they align with product requirements and production feasibility. Fabric selection is based on actual performance, not labels alone. The goal is to balance responsible sourcing with durability, fit accuracy, and wash consistency.

Sustainable fabric choices are often more effective when combined with controlled manufacturing processes, such as optimized cutting plans and responsible washing methods. Fabric alone does not define sustainability in production.

Choosing the Right Denim Fabric for Production

Selecting the right denim fabric is a collaborative process between the brand and the manufacturer. Design intent, target market, fit requirements, and order scale all influence the final decision.

From a factory perspective, our role is to provide clear guidance on how different denim fabrics will behave during production and after wear. This helps brands make informed decisions and avoid unnecessary risks during bulk manufacturing.

Denim fabric options should always be evaluated in context. There is no single “best” fabric—only the most suitable one for a specific product and production plan.