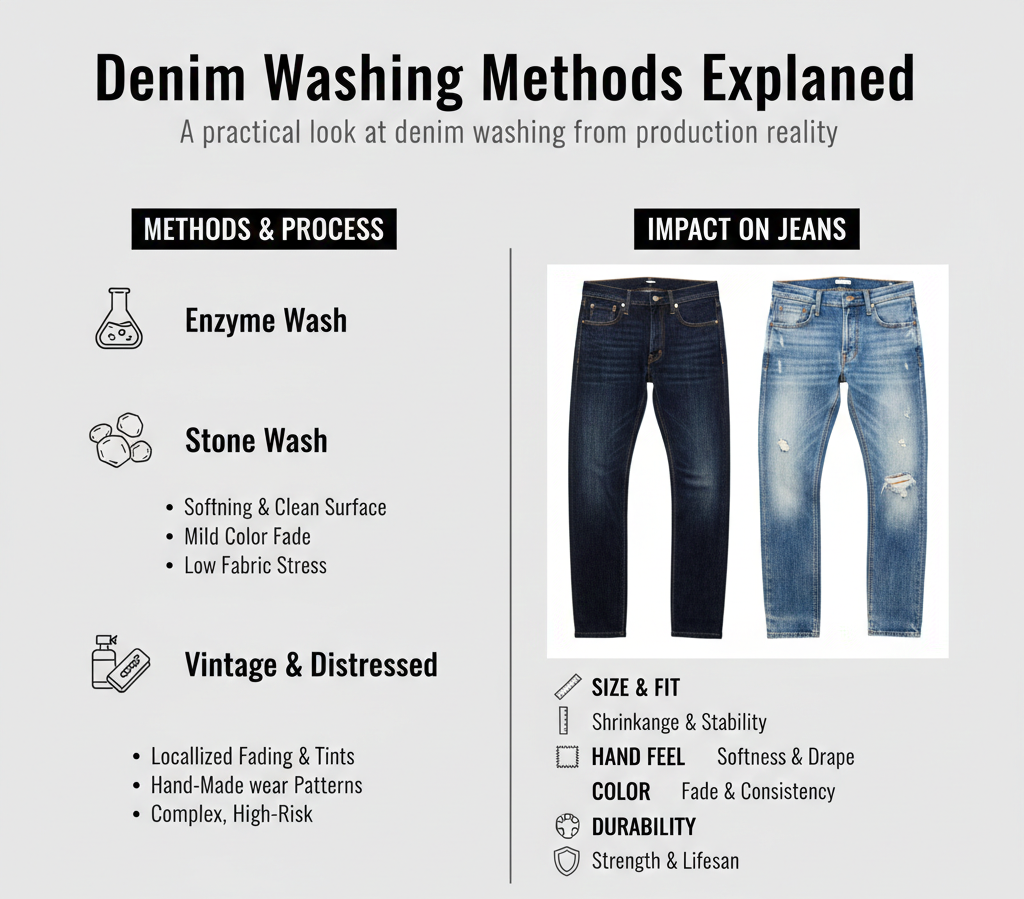

A practical look at denim washing from production reality

In denim manufacturing, washing is not a decorative step added at the end.

It directly changes fabric behavior, garment size, hand feel, color stability, and long-term wear performance.

Many brands first think about washing in visual terms — light, dark, vintage, clean.

Factories think about washing as a controlled process that affects fit, yield, and risk.

This Pages explains the most common denim washing methods used in production, how they work, and what they actually change in a finished pair of jeans.

Why denim washing matters more than brands expect

Before talking about methods, it helps to understand what washing really does.

From a production point of view, washing affects four core areas:

- Garment size and tolerance

- Fabric shrinkage and recovery

- Surface texture and softness

- Color stability over time

A wash decision made late — or copied from another style — is one of the most common reasons for:

- Fit changes between sample and bulk

- Inconsistent sizing across batches

- Customer complaints after wear

That’s why experienced factories treat washing as part of development, not decoration.

What happens to denim during washing?

Denim fabric goes through physical and chemical changes during washing.

At a basic level:

- Fibers relax

- Yarn twist opens slightly

- Dye on the surface is reduced or redistributed

- Fabric density changes

These changes are irreversible.

Once a garment is washed, its behavior is set.

That’s why wash testing must happen before finalizing patterns and grading.

Enzyme wash: controlled softening and color reduction

Enzyme washing is one of the most widely used denim washing methods today.

How enzyme washing works

Enzymes target the surface fibers of denim yarns.

They gently remove loose fibers and reduce indigo on the fabric surface.

The result is:

- Softer hand feel

- Cleaner surface

- Mild color fade

Where enzyme wash works best

Enzyme wash is commonly used for:

- Everyday men’s and women’s jeans

- Stretch denim styles

- Clean casual collections

Because it is controllable, enzyme washing is often used as a base wash, sometimes combined with other techniques.

Production considerations

From a factory standpoint:

- Temperature control is critical

- Over-processing can weaken fabric

- Stretch denim requires lower heat and shorter cycles

Poor enzyme control can lead to uneven color or unexpected size changes.

Stone wash: texture and contrast through abrasion

Stone washing is a more aggressive method compared to enzyme wash.

How stone washing works

Pumice stones are added to the washing machine.

As garments tumble, the stones abrade the fabric surface.

This creates:

- Stronger color contrast

- Visible wear patterns

- A more broken-in look

Typical use cases

Stone wash is often used for:

- Vintage-inspired jeans

- Workwear styles

- Rigid or low-stretch denim

It is less common for lightweight or high-stretch fabrics.

Factory risks to manage

Stone washing introduces higher risk:

- Fabric damage if stones are too rough

- Inconsistent abrasion between garments

- Higher machine wear

For this reason, many factories now use reduced stone wash combined with enzyme processes.

Vintage and distressed washes: visual impact with technical limits

Vintage and distressed washes aim to recreate long-term wear in a short time.

Common vintage wash techniques

These may include:

- Enzyme + stone combinations

- Localized abrasion

- Tinting or overdye

- Controlled fading zones

Each step adds visual depth, but also adds variability.

What brands often overlook

Vintage washes look great in photos, but:

- They increase size tolerance variation

- They reduce fabric strength

- They amplify differences between fabric batches

From a production view, distressed washes require:

- Extra QC checks

- Clear approval standards

- Realistic yield expectations

Factories usually recommend locking fabric choice early when planning vintage programs.

Clean and minimal wash: stability over drama

Clean wash styles are often underestimated.

What defines a clean wash

Clean washes focus on:

- Minimal color loss

- Smooth surface

- Stable sizing

The goal is not to hide the fabric, but to let it speak.

Why factories like clean washes

From a manufacturing perspective, clean washes:

- Offer better size consistency

- Reduce fabric stress

- Lower rejection rates

They are ideal for:

- Premium basics

- Office-friendly denim

- Long-term core styles

Clean wash does not mean “no wash” — it means controlled and intentional washing.

How washing affects stretch denim differently

Stretch denim requires special attention in washing.

Key risks with stretch denim

Elastane fibers are sensitive to:

- Heat

- Mechanical stress

- Over-processing

If damaged, elastane loses recovery.

This leads to baggy knees, loose waist, and short wear life.

Factory controls for stretch washing

To reduce risk, factories adjust:

- Lower wash temperature

- Shorter processing time

- Reduced mechanical action

Stretch denim washing must be tested with actual bulk fabric, not just sample yardage.

Shrinkage, recovery, and size control

Every wash causes some level of shrinkage.

The difference is whether it is:

- Predictable

- Consistent

- Accounted for in pattern making

Factories measure:

- Length shrinkage

- Width shrinkage

- Post-wash recovery

This data feeds directly back into:

- Pattern adjustment

- Grading logic

- Size spec confirmation

Skipping this step is one of the fastest ways to create bulk fit problems.

Sampling vs bulk: where washing problems start

Many washing issues do not appear in samples.

Why?

- Sample washing loads are smaller

- Machines behave differently

- Fabric batches are limited

In bulk:

- Load weight increases

- Fabric variation appears

- Minor wash differences compound

That’s why factories insist on:

- Pre-production wash tests

- Bulk fabric approval

- Tolerance alignment before cutting

Choosing washing methods based on brand goals

Instead of asking “Which wash looks best?”, factories ask:

- What fit tolerance can the brand accept?

- Is repeatability more important than effect?

- Will this style be reordered?

For long-term styles, stable washes often outperform dramatic ones.

Common washing mistakes factories see

From production experience, the most common issues are:

- Applying heavy vintage washes to stretch denim

- Copying wash effects without matching fabric

- Approving sample wash without bulk testing

- Ignoring wash impact on grading

Most washing problems are not visual mistakes — they are planning mistakes.

Washing as part of the development process

In professional denim production, washing is not the last step.

It interacts with:

- Fabric selection

- Pattern development

- Fit approval

- Quality control

When washing is planned early, it reduces surprises later.

How this page fits into the Washing & Finishing Hub

This page explains what washing methods are and how they behave.

Related pages go deeper into:

- Stretch denim washing risks

- Vintage wash vs clean wash decisions

- How washing changes fit over time

Together, they form a complete picture of washing from a manufacturing view.

Final thought from the factory floor

Good washing does not shout.

It supports the fit, protects the fabric, and stays consistent across production.

Brands that understand washing as a technical process — not just an effect —

tend to have fewer returns, fewer remakes, and more repeat orders.