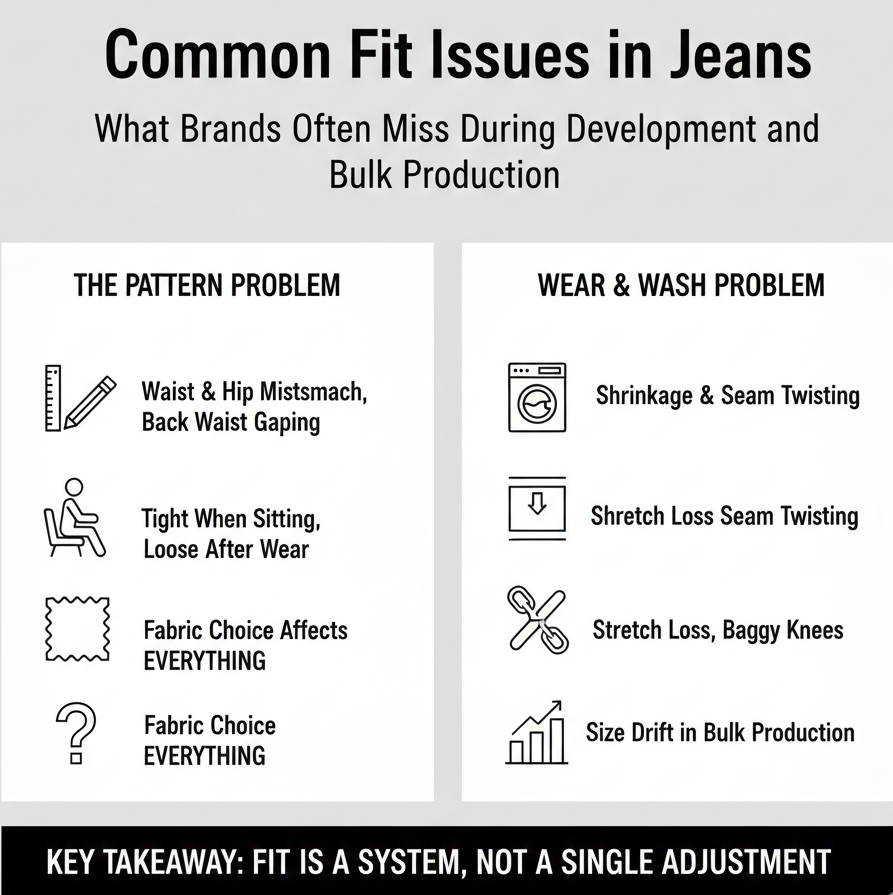

What Brands Often Miss During Development and Bulk Production

Fit problems are one of the most common reasons jeans fail in the market.

Not because the design is bad, but because fit behaves differently once a product moves from idea, to sample, to bulk production, and finally to real customers.

Many brands only notice fit issues after sales begin—through returns, reviews, or repeat complaints. From a factory point of view, most of these problems are predictable. They come from small decisions made early in fabric choice, pattern setup, grading logic, or wash planning.

Below are the fit issues we see most often in jeans production, why they happen, and how they usually show up after launch.

Why Do Jeans Often Fit Well as Samples but Fail in Bulk?

This is one of the most common questions from new brands.

During sampling, fit is tested on one size, with one fabric lot, and often with a lighter or simplified wash. Everything is controlled. Once bulk production starts, several things change at the same time:

- Fabric comes from a full production batch, not a sample roll

- Multiple sizes are produced, not just the base size

- Washing is scaled up, not tested one-by-one

- Sewing tension varies across production lines

Each change may look small, but combined, they affect how the garment sits on the body.

Fit issues are rarely caused by one mistake. They usually come from stacked variables that were not tested together early enough.

Why Is the Waist Comfortable but the Hip or Thigh Feels Tight?

This issue appears often in women’s jeans and slim men’s fits.

The most common cause is grading logic, not fabric stretch. Many brands grade waist, hip, and thigh using the same ratio across sizes. In real bodies, these areas do not grow evenly.

From a factory perspective, problems usually come from:

- Over-scaling the waist while under-scaling the hip

- Using straight grading rules copied from another brand

- Not adjusting thigh allowance when switching fabrics

In stretch denim, this issue can be hidden during fitting because the fabric compensates. In non-stretch denim, it becomes obvious immediately.

Once production starts, this type of issue is hard to fix without reworking the pattern.

Why Do Jeans Feel Good at First but Lose Shape After Wear?

Customers often describe this as “baggy knees,” “sagging seat,” or “the jeans feel bigger after a few hours.”

This is almost always related to stretch recovery, not fit size.

Common causes include:

- Low-quality or unstable elastane yarn

- Overstretching during sewing

- High wash temperatures damaging elastic fibers

- Using stretch fabric without recovery testing

From a manufacturing point of view, stretch denim is not forgiving. Two fabrics with the same stretch percentage can behave very differently after wear and wash.

Brands sometimes try to solve this by reducing size, which usually creates new complaints. The real fix is fabric selection and process control, not size reduction.

Why Does the Back Waist Gap Even When the Size Is Correct?

Back waist gaping is one of the most frustrating fit complaints, especially for women’s jeans.

This issue is rarely about body shape alone. In production, it often comes from:

- A flat back waist curve in the pattern

- Insufficient difference between waist and hip measurement

- Fabric stiffness not matching the pattern structure

- Rise length not aligned with body posture

In many cases, the pattern was developed on a fitting model with a different posture than the target customer.

Factories often see this issue when brands reuse a men’s base block or a standard block without adjusting back rise geometry.

Why Do Some Jeans Feel Tight When Sitting but Fine When Standing?

This problem is common in rigid or low-stretch denim.

Typical causes include:

- Insufficient front rise depth

- Inadequate crotch extension

- Fabric weight too heavy for the silhouette

- Wash shrinkage reducing ease in seated positions

In fitting sessions, models usually stand. If sitting tests are skipped, this issue may not be noticed until customers start wearing the product daily.

From a factory view, this is a pattern engineering issue, not a size issue.

Why Does the Same Size Fit Differently Across Washes?

Brands are often surprised when a clean wash fits better than a heavy wash, even though the pattern is the same.

Washing affects fit in several ways:

- Shrinkage alters length and width

- Heat changes fabric density

- Mechanical action affects stretch recovery

- Distressing removes fabric tension

If fit is approved only on one wash type, the other washes may drift out of tolerance.

Factories usually recommend approving fit after the final wash, not before, especially for vintage or distressed programs.

Why Do Men’s and Women’s Jeans Show Different Fit Problems?

Men’s fit issues tend to focus on consistency and durability. Women’s fit issues often relate to comfort balance and shape alignment.

From production experience:

- Men’s jeans suffer more from size inconsistency between batches

- Women’s jeans suffer more from body variation mismatch

Using the same development logic for both usually creates problems.

Men’s patterns tolerate rigid fabric better. Women’s patterns require closer coordination between fabric behavior, grading, and rise shaping.

Why Do Plus Size Jeans Have Higher Return Rates?

Plus size fit issues are rarely solved by simply scaling up a regular size range.

Common mistakes include:

- Linear grading across extended sizes

- Insufficient thigh and seat allowance

- Waist stretch doing too much of the work

- Ignoring weight distribution differences

Factories that specialize in plus size usually develop separate base patterns rather than extending standard ones.

Fit success in plus size denim depends more on pattern structure than on stretch percentage.

Why Does Fit Change After Reordering the Same Style?

This is one of the most painful issues for growing brands.

Common reasons include:

- Fabric substitution due to availability

- Slight changes in yarn or finishing

- Different washing batches

- Production in a different season

Even when specs are the same, fabric behavior can change. Without clear tolerance standards and fit checkpoints, drift is almost unavoidable.

Factories often recommend rechecking fit whenever fabric supply changes, even if the style number stays the same.

Why Are Fit Complaints Often About “Feel,” Not Measurements?

Customers rarely talk in centimeters or inches. They describe fit emotionally:

- “Feels tight here”

- “Doesn’t move with me”

- “Feels bigger after wear”

These complaints usually reflect interaction between fabric, pattern, and wear behavior.

From a production point of view, good fit is not only about measurements. It’s about how the garment behaves during movement, sitting, washing, and repeated wear.

This is why fit development cannot be rushed or treated as a one-time step.

How Can Brands Reduce Fit Issues Before Launch?

From factory experience, the most effective steps are:

- Test fit on final fabric and wash

- Review grading logic early, not after complaints

- Conduct sitting and movement tests

- Separate development logic for stretch and non-stretch

- Avoid last-minute fabric or wash changes

Fit problems are expensive to fix after launch, but relatively manageable during development.

Fit Problems Are Rarely Accidental

Most jeans fit issues do not come from poor sewing or careless workers. They come from decisions made early, often with limited information.

Brands that treat fit development as an ongoing process—rather than a box to check—tend to see lower returns, better reviews, and more stable reorders.

From a manufacturing perspective, fit is not a styling detail. It is a system that connects fabric, pattern, washing, and real-world use.

Related Pages

- How Stretch Denim Affects Fit

- Plus Size Denim Pattern Logic

- Sampling to Bulk Production

- Denim Washing Methods Explained