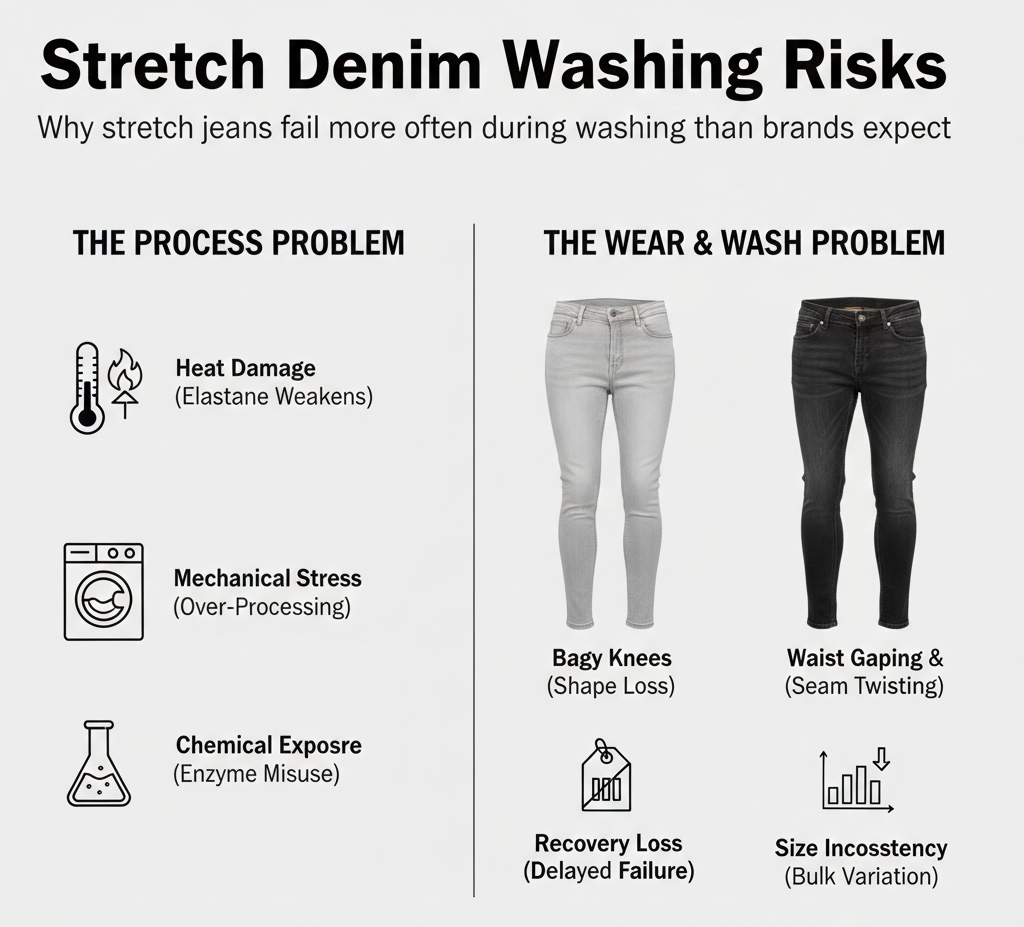

Why stretch jeans fail more often during washing than brands expect

Stretch denim is often chosen to improve comfort and fit.

But in real production, many quality problems in stretch jeans do not come from sewing or fabric sourcing — they start in the washing process.

From a factory point of view, stretch denim is not “normal denim plus comfort.”

It is a fabric system that reacts differently to heat, water, chemicals, and mechanical force.

When washing is not adjusted correctly, stretch denim becomes one of the highest-risk categories in jeans manufacturing.

Why stretch denim reacts differently in washing

The key difference between stretch and non-stretch denim is not appearance — it is fiber behavior.

Stretch denim contains elastane (or similar elastic fibers).

These fibers are designed to stretch and recover, but they are also sensitive and irreversible once damaged.

During washing, elastane is exposed to:

- Heat

- Chemical agents

- Mechanical stress

- Time under tension

If any of these are not controlled, recovery loss happens quietly — and shows up only after wear.

Heat damage: the most common stretch denim washing risk

Heat is the number one enemy of elastane.

What happens when heat is too high

When washing temperature exceeds safe limits:

- Elastane fibers weaken

- Recovery rate drops

- Fabric stretches but does not return fully

The jeans may still look fine after washing.

The problem appears after 1–3 wears, when knees bag out or the waist loses shape.

This is one of the hardest problems to fix after bulk production.

Over-washing and mechanical stress

Stretch denim does not tolerate aggressive washing cycles well.

Where mechanical stress comes from

- Long washing time

- High drum rotation

- Heavy load weight

- Stone or abrasive contact

Even when temperature is controlled, mechanical stress alone can damage elastane.

Factory reality

Two washes with the same chemicals but different machine settings can produce very different results.

That’s why stretch denim washing must be tested on actual production machines, not just sample lab tests.

Chemical exposure and enzyme misuse

Enzymes are widely used in denim washing, but they must be handled carefully with stretch fabrics.

Common enzyme-related risks

- Over-processing reduces fabric strength

- Combined enzyme + stone programs increase stress

- Incorrect neutralization continues fiber damage

Enzymes act on cotton fibers, but elastane suffers from the environment created during the process.

Factories usually shorten enzyme cycles and lower intensity when stretch is involved.

Recovery loss: the silent failure

Stretch denim problems are often invisible at inspection.

Why recovery loss is dangerous

- Size specs may still pass

- Appearance looks acceptable

- Fabric feels soft and comfortable

But recovery loss shows up later:

- Baggy knees

- Sagging seat

- Waistline relaxation

From a brand perspective, this leads to:

- High return rates

- Negative fit reviews

- Reduced repeat orders

From a factory perspective, this is one of the most expensive failures.

Why stretch washing problems appear in bulk, not samples

Many brands say:

“The sample was fine. Why did bulk fail?”

There are real reasons.

Differences between sampling and bulk washing

- Sample loads are smaller

- Machines behave differently under weight

- Fabric variation is limited in samples

In bulk:

- Load weight increases

- Heat distribution changes

- Mechanical force increases

Stretch denim that survives sample washing may not survive bulk conditions unless parameters are adjusted.

Fabric batch variation and stretch consistency

Stretch denim performance is not only about elastane percentage.

Two fabrics both labeled “2% elastane” can behave very differently due to:

- Elastane quality

- Core-spun yarn structure

- Weaving tension

- Fabric finishing history

If washing programs are copied without testing each batch, recovery issues increase.

Factories often insist on:

- Bulk fabric wash testing

- Recovery measurement after washing

- Approval before cutting

Skipping this step is a major risk multiplier.

Stretch denim + vintage wash: a risky combination

Vintage and distressed washes are popular, but they are not stretch-friendly by default.

Why vintage effects are risky

Vintage washes often involve:

- Longer washing cycles

- Abrasion

- Higher mechanical stress

These conditions accelerate elastane damage.

Factory recommendation:

If a strong vintage look is required, consider:

- Lower stretch percentage

- Hybrid fabric options

- Adjusted wash aesthetics

Trying to force heavy vintage effects on high-stretch denim often leads to failure.

Fit distortion caused by washing stretch denim

Washing affects not only stretch recovery, but also garment shape.

Common issues include:

- Leg twisting

- Uneven inseam length

- Waist distortion

- Pocket deformation

These problems are amplified in stretch denim because the fabric moves more during washing.

That’s why pattern allowance for stretch denim must consider wash behavior, not just fabric specs.

How factories reduce stretch denim washing risks

From a production standpoint, risk control usually includes:

- Lower wash temperature

- Shorter processing time

- Reduced mechanical action

- Controlled load weight

- Separate programs for stretch vs rigid denim

Most importantly:

Stretch denim wash parameters should never be copied from non-stretch styles.

When stretch denim is still the right choice

Despite the risks, stretch denim is still the right solution for many products.

It works well when:

- Fit comfort is critical

- Silhouettes are close-fitting

- Washing effects are moderate

- Recovery is tested and controlled

Problems arise not because stretch denim is wrong — but because it is treated like rigid denim.

Questions brands should ask before approving stretch washes

Before bulk production, brands should ask:

- Has recovery been tested after washing?

- Are washing parameters adjusted for elastane?

- Was bulk fabric used in testing?

- Can the factory repeat this wash consistently?

If these questions do not have clear answers, risk is high.

How this page connects to your washing decisions

This page focuses on risk, not aesthetics.

To build a complete washing strategy, it should be read together with:

- An overview of denim washing methods

- A comparison of vintage wash vs clean wash

- An understanding of how washing changes fit

Together, these pages help brands make washing decisions that survive real production.

Final note from the factory side

Stretch denim failures are rarely dramatic at first.

They are quiet, delayed, and expensive.

Most of them could be avoided with:

- Better wash planning

- Earlier testing

- Clear separation between stretch and rigid processes

In denim manufacturing, washing does not just finish the product.

It decides how long the product stays acceptable after it leaves the factory.