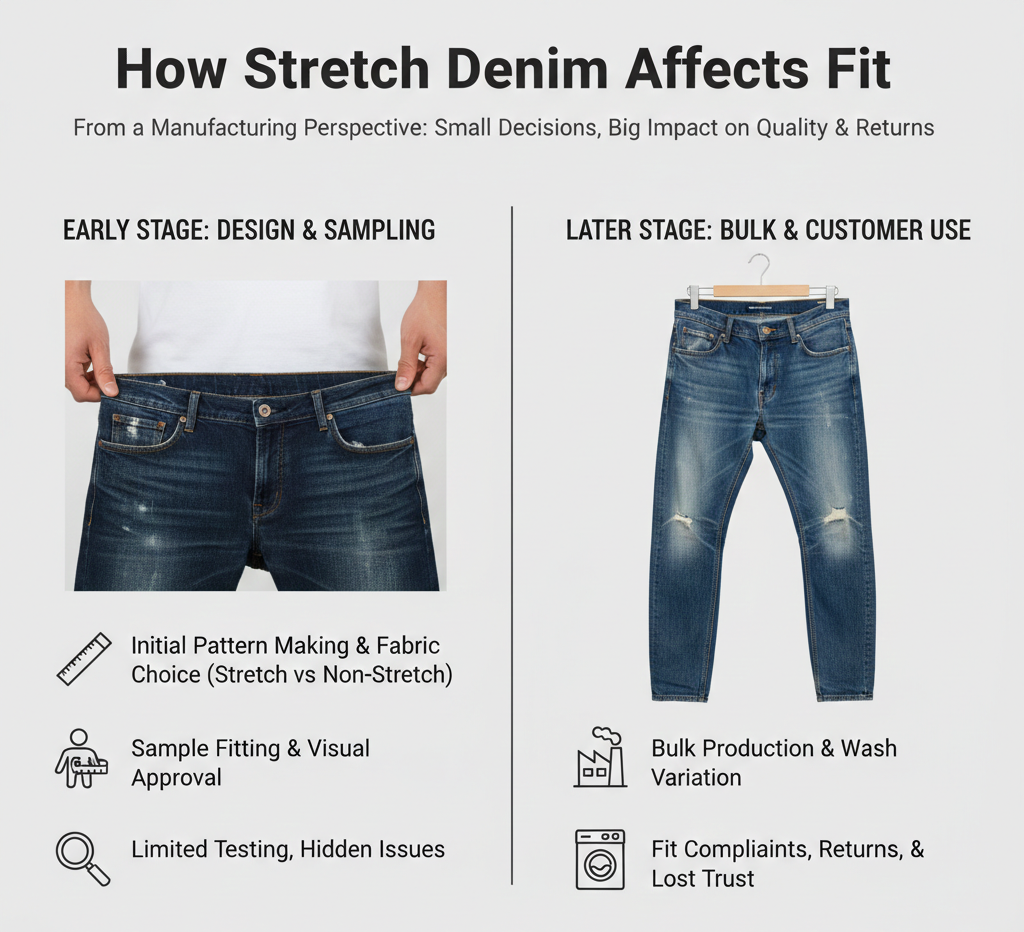

Stretch denim is often treated as a shortcut to better fit.

In early sampling, that assumption usually feels true. The jeans are easier to wear, sizing seems forgiving, and fewer complaints show up during fittings.

But once production moves from samples to bulk, stretch becomes one of the most common sources of fit inconsistency.

From a manufacturing point of view, stretch denim does not simply “add comfort.” It changes how patterns behave, how measurements settle after wash, and how garments respond to real wear. Understanding these effects early makes a noticeable difference in return rates, size complaints, and long-term customer satisfaction.

Why does stretch denim feel easier during sampling?

In sample development, stretch denim hides small problems.

A waistband that is slightly tight, a hip that is a bit narrow, or a thigh that should have more ease can still feel acceptable when the fabric stretches on the body. During fittings, this creates a sense that the pattern is “almost right” or “good enough.”

From the factory side, this is where risk begins.

Because the fabric stretches under tension, early fit sessions often rely on how the garment feels when worn, not how it measures when relaxed. Once washing, heat, and repeated wear enter the process, those hidden issues start to surface.

What changes when elastane is added to denim?

Stretch denim behaves differently at every stage of production.

Adding elastane affects:

- Fabric elongation under tension

- Recovery after wear

- Reaction to heat and chemicals

- How seams and waistbands hold shape

Two fabrics with the same elastane percentage can behave very differently depending on yarn quality, construction, and finishing. This is why factories rarely judge stretch denim by composition alone.

From a fit perspective, stretch changes the balance between pattern control and fabric behavior.

How does stretch affect pattern accuracy?

With non-stretch denim, patterns must do most of the work. If the waist, rise, or hip is wrong, the problem shows immediately.

Stretch denim shifts part of that responsibility from the pattern to the fabric.

This often leads to three common outcomes during development:

- Patterns are approved with less precision

- Ease allowances are reduced too much

- Grading relies on fabric stretch instead of geometry

In small sample quantities, this can pass unnoticed. In bulk production, it leads to inconsistent fit across sizes.

Factories see this often when brands use the same base pattern for stretch and non-stretch fabrics without adjustment.

Why does stretch denim fit change after washing?

Washing is where stretch denim reveals its limits.

Elastane fibers are sensitive to:

- High temperature

- Mechanical stress

- Aggressive enzyme or stone washes

If the washing process is not adapted for stretch denim, the fabric may lose part of its recovery. The jeans still stretch, but they do not fully return to shape.

From the customer’s point of view, this shows up as:

- Waistbands that relax after a few wears

- Knees that bag out

- Seat areas that lose structure

From the factory’s point of view, these issues often trace back to wash control, not sewing quality.

Does more stretch always improve comfort?

Not necessarily.

Comfort depends more on recovery than on stretch percentage.

High-stretch denim with poor recovery feels comfortable at first but loses shape quickly. Low-stretch denim with good recovery often performs better over time, especially for everyday wear.

This is why many factories recommend controlled stretch levels, often between 1% and 2%, rather than higher elastane content.

The goal is not maximum stretch, but balanced behavior across wear, wash, and time.

How does stretch denim affect size consistency in bulk?

In bulk production, stretch denim introduces variability that non-stretch fabrics usually avoid.

Common issues include:

- Fabric batch differences in recovery

- Variation in elastane tension during weaving

- Heat exposure during drying or pressing

These factors can cause the same pattern to behave differently across production lots. Measurements taken immediately after sewing may not match measurements after washing and resting.

Factories manage this by adding extra checkpoints, including relaxed measurement standards and recovery testing. When these steps are skipped, size consistency suffers.

Why do stretch jeans return more often despite “better fit”?

From return data shared by brands, stretch jeans often receive complaints after several wears, not after first try-on.

Typical reasons include:

- Waist grows during the day

- Jeans feel loose after sitting

- Shape does not hold after washing

These are not sizing issues in the traditional sense. They are performance issues tied to fabric recovery and wash control.

Brands that rely on stretch to solve fit problems without addressing these factors often see higher long-term return rates.

How should stretch be handled differently for women’s jeans?

Stretch denim plays a larger role in women’s jeans, especially for close-fitting silhouettes.

However, this also increases risk.

Women’s fits involve greater shape variation between waist, hip, and thigh. When stretch compensates for pattern limitations, small grading errors are magnified across sizes.

Factories typically recommend:

- Lower stretch with stronger recovery

- More precise waist and hip shaping

- Separate grading logic from men’s patterns

Using stretch as support, not as a replacement for fit engineering, leads to more stable results.

What about plus-size jeans and stretch denim?

Stretch is often assumed to be essential for plus-size denim, but this is only partly true.

High stretch can improve comfort, but it also increases the risk of sagging and distortion if recovery is weak. In plus-size fits, fabric stress is higher, especially at the seat and thigh.

Factories usually focus on:

- Engineered stretch placement

- Strong waistband construction

- Controlled ease rather than high elasticity

In many cases, moderate stretch with correct pattern balance performs better than highly elastic fabrics.

Can the same pattern work for stretch and non-stretch denim?

In theory, yes. In practice, rarely.

Stretch denim allows patterns to appear correct even when ease distribution is not ideal. Non-stretch denim exposes these issues immediately.

Factories often see brands approve patterns in stretch denim, then switch to non-stretch later and encounter major fit problems.

Even within stretch categories, changes in fabric supplier or elastane quality usually require pattern adjustment.

Patterns and fabric should be developed together, not separately.

How do factories test stretch impact on fit?

Factories do not rely on wear feeling alone.

Common internal checks include:

- Stretch and recovery testing

- Relaxed measurement comparison

- Post-wash fit evaluation

- Multiple wear simulations

These steps help identify whether stretch is supporting the fit or masking problems.

Brands that allow time for this testing during development usually experience fewer bulk surprises.

When does stretch denim make sense?

Stretch denim works best when:

- The silhouette requires close fit

- Recovery performance is tested

- Washing processes are controlled

- Patterns are built specifically for stretch

It becomes risky when used to compensate for unclear sizing, rushed development, or limited fitting sessions.

Stretch is a tool, not a solution by itself.

How should brands decide whether to use stretch?

Instead of asking “Will stretch make this more comfortable?”, factories usually ask different questions:

- Will the wash damage recovery?

- Can the pattern hold shape without relying on stretch?

- How sensitive is this style to size variation?

- What complaints are most costly after launch?

When these questions are addressed early, stretch denim becomes predictable rather than problematic.

A practical takeaway from the factory floor

Stretch denim does not remove fit risk. It changes where that risk appears.

Brands that understand this treat stretch as part of a controlled system — fabric choice, pattern development, washing, and quality checks working together.

Those that do not often discover fit problems after customers start wearing the jeans, when fixes are already expensive.

Related reading

- Common Fit Issues in Jeans

- Stretch vs Non-Stretch Denim

- Denim Washing Methods Explained

- Plus Size Denim Pattern Logic