Understanding the Real Differences Before You Commit to Production

In denim sourcing, selvedge fabric often comes up early in conversations.

Sometimes it is brought up by designers who like the look.

Sometimes by brand founders who associate it with “premium.”

And sometimes by buyers who feel selvedge is something they should consider, even if they are not sure why.

Non-selvedge denim, by contrast, rarely gets the same attention. It is often treated as the default option, or even as a less special one.

In production, however, these two fabrics behave very differently. The choice between selvedge and non-selvedge denim affects how patterns are made, how fabric is used, how washing can be done, and how stable your bulk order will be. These differences usually do not show up clearly at the sketch or sampling stage—but they show up later.

Understanding those differences early helps brands avoid design compromises, cost surprises, and production friction.

What Selvedge Denim Really Means in Production

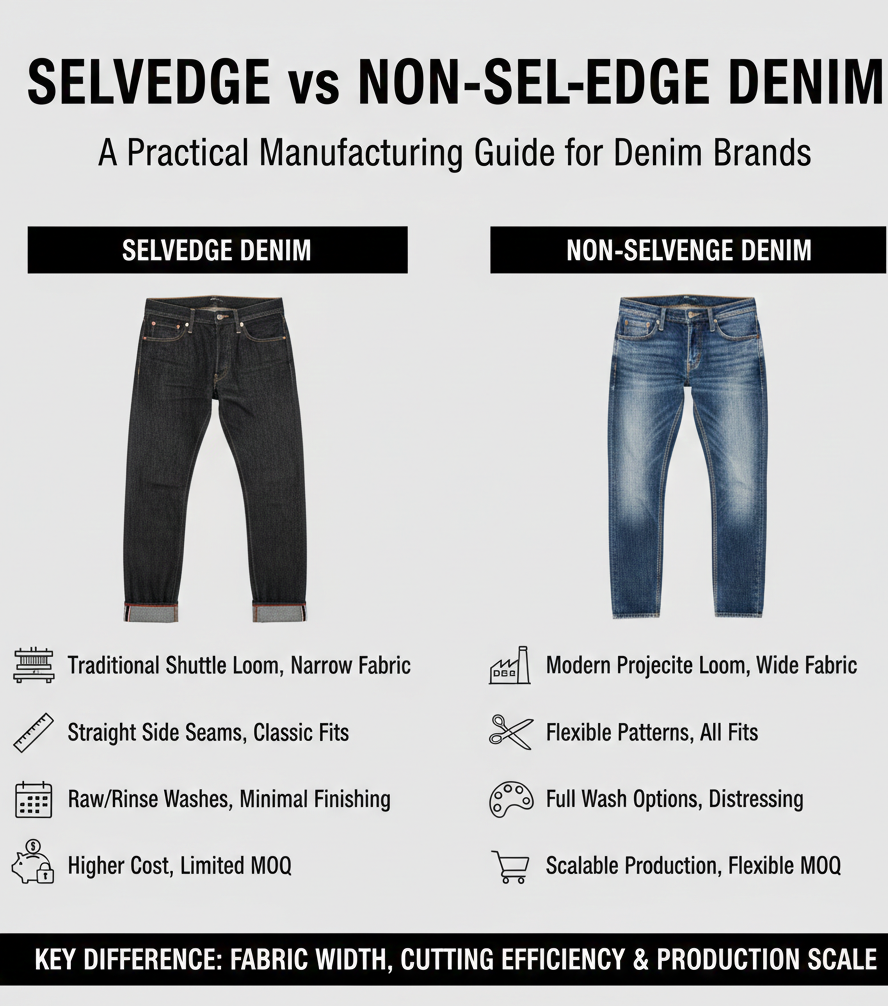

Selvedge denim is woven on shuttle looms.

These looms produce fabric slowly and at a narrow width. The edge of the fabric finishes itself during weaving, which is why it does not fray.

From a visual point of view, the selvedge edge can look clean and intentional, especially when shown on a cuff or exposed seam. From a production point of view, that same edge creates very specific rules.

Most selvedge denim is woven at around 28 to 32 inches wide. This is less than half the width of most modern denim fabrics. As a result, cutting plans need to be adjusted, fabric consumption increases, and layout flexibility becomes limited.

Selvedge denim is not just a fabric choice. It is a commitment to a certain way of making jeans.

How Non-Selvedge Denim Became the Industry Standard

Non-selvedge denim is woven on modern looms such as projectile or air-jet machines. These looms are faster and produce much wider fabric. After weaving, the fabric edges are cut and finished later during garment construction.

This method allows for higher consistency, larger production volumes, and more fabric options. It also makes pattern placement more efficient, which is one of the reasons non-selvedge denim dominates global denim production today.

Most consumers wear non-selvedge denim without realizing it. The difference is not about quality alone. It is about scale, control, and flexibility.

Fabric Width and Its Impact on Cost and Waste

One of the most practical differences between selvedge and non-selvedge denim is fabric width.

With selvedge denim, narrow width means patterns must be placed carefully to preserve the selvedge edge. This often leads to lower marker efficiency and higher fabric usage per garment.

In non-selvedge production, wider fabric allows patterns to be nested more efficiently. This reduces waste and makes cost planning more predictable, especially in bulk orders.

For small runs, the difference may feel manageable. As quantities increase, fabric efficiency becomes a much bigger factor in overall cost.

Pattern Design Limitations You Should Know About

Selvedge denim works best with simple, traditional jean constructions. Straight side seams and classic silhouettes allow the selvedge edge to remain visible and meaningful.

When designs become more complex—curved seams, aggressive tapering, or multi-panel construction—the selvedge edge often disappears or becomes irrelevant. In those cases, brands still pay the cost of selvedge denim without gaining its visual benefit.

Non-selvedge denim places far fewer limits on pattern development. It supports a wider range of fits and silhouettes and makes it easier to adjust patterns during development.

From a factory standpoint, pattern freedom often leads to better fit control.

Fit Stability from Sample to Bulk

Rigid selvedge denim, usually made from 100% cotton, is unforgiving.

If the pattern is slightly off, the wearer will feel it immediately.

The advantage is that once the pattern is correct and the fabric batch is stable, fit consistency tends to be good in bulk production. There is less stretch behavior to manage, and fewer variables related to recovery.

Non-selvedge denim may include stretch or blended fibers, depending on the fabric. This can make samples feel more comfortable, but it also introduces more variables in bulk—especially after washing.

Neither option guarantees better fit by default. Fit quality depends on how well the fabric, pattern, and washing process are aligned.

Washing and Finishing: Where Limits Become Clear

Selvedge denim is often paired with raw or lightly washed finishes, and there is a reason for that.

Heavy washing processes—such as strong stone wash or aggressive distressing—can damage the selvedge edge or reduce its visual value. In some cases, the edge becomes uneven or loses its clean appearance.

For brands planning complex wash programs, non-selvedge denim offers more freedom. It handles a wider range of treatments without compromising structural integrity.

This does not mean selvedge denim cannot be washed. It means washing choices must be controlled and intentional.

Wear Behavior and Long-Term Use

Many customers who choose selvedge denim expect a break-in period. The fabric may feel stiff at first, but it softens with wear and develops personal fading over time.

Non-selvedge denim is often designed to feel comfortable earlier in its life cycle. This suits customers who value immediate wearability or fashion-driven silhouettes.

From a brand perspective, it is important to match fabric choice with customer expectations. Selvedge denim attracts a more informed and patient customer. Non-selvedge denim appeals to a broader audience.

Supply Chain and MOQ Reality

Selvedge denim is produced in smaller quantities by fewer mills. Fabric availability can be limited, and lead times may be longer. Minimum order quantities are often higher, not because factories insist on it, but because mills run selvedge fabric in smaller batches.

Non-selvedge denim offers more sourcing options. Mills produce it in larger volumes, making MOQs more flexible and substitutions easier if issues arise.

For first collections or test launches, this flexibility can reduce risk significantly.

Common Misunderstandings We See in Sourcing

In production, some issues come up repeatedly:

- Choosing selvedge denim for designs that hide the selvedge edge

- Expecting complex vintage washes on selvedge fabric

- Assuming selvedge automatically means better quality

- Underestimating fabric consumption during costing

Most of these problems are not design mistakes. They come from incomplete understanding of how selvedge denim behaves once production starts.

Making the Decision More Practical

Instead of asking whether selvedge or non-selvedge denim is “better,” it helps to ask more specific questions:

- Does the selvedge edge add visible value to the design?

- Can the pattern work within selvedge width limits?

- Are wash requirements compatible with the fabric?

- Does the target customer understand what selvedge means?

- Is the supply chain stable enough for repeat orders?

When these questions are answered clearly, the right choice usually becomes obvious.

A Balanced Approach Many Brands Take

Some brands choose to work with both options. Selvedge denim may be used for limited runs, heritage styles, or core classics. Non-selvedge denim may support seasonal collections or fashion-forward designs.

This approach allows brands to balance storytelling with production efficiency.

From a factory perspective, the most successful projects are not those that chase labels, but those that align fabric choice with real production needs.

Closing Thoughts from the Production Floor

Selvedge denim is not a shortcut to premium positioning.

Non-selvedge denim is not a compromise.

Both are tools. When used with clear intent, either can support a strong product.

What matters most is understanding how the fabric behaves beyond the sample stage—during cutting, washing, bulk production, and long-term wear. Brands that take the time to understand these details make better decisions and face fewer surprises later.

Related Reading

- Stretch vs Non-Stretch Denim

- Denim Weights Explained

- Raw Denim vs Washed Denim

- Denim Fabric Options for Jeans Manufacturing

- Quality Control in Denim Production