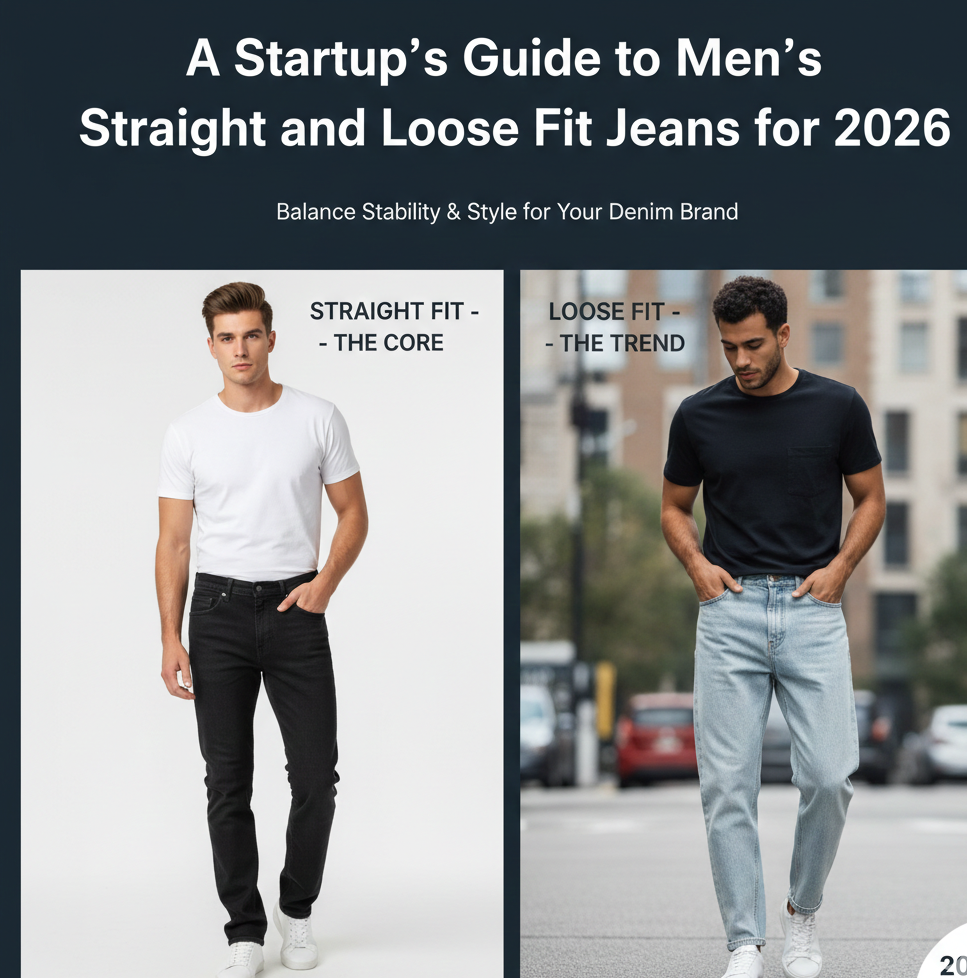

For denim startups launching in 2026, the strategy has shifted. The market is moving away from restrictive cuts toward Straight and Loose fits. For a new brand, these aren’t just “trends”—they are the foundation of a stable inventory.

From a manufacturing perspective, these fits require precise pattern engineering to look “premium” rather than “sloppy.” This guide outlines the technical and commercial roadmap for importers and startup founders to source these styles effectively.

1. The 70/30 Inventory Rule: Balancing Revenue and Buzz

For your first launch, we recommend the 70/30 Strategy. This balances low-risk sales with brand-building trend pieces.

- 70% Straight Fit (The Anchor): This is your recurring revenue. A mid-rise, consistent leg width (think 15.5″–16.5″ leg opening) appeals to the 25–45 age bracket. It has the lowest return rate in the industry.

- 30% Loose Fit (The Identity): This captures the 2026 “Comfort Wave.” It features a roomier thigh and a subtle taper. It builds your brand’s “fashion-forward” reputation among Gen Z and streetwear enthusiasts.

2. Technical Fabric Selection for Mid-to-High-End Denim

High-end buyers can feel the difference in grain and weight. Choosing the wrong fabric for a loose fit can make the garment look cheap.

| Fit Category | Recommended Fabric | Weight (oz) | Technical Benefit |

| Classic Straight | 100% Cotton Ring-Spun | 13.5 – 14.5 oz | Holds a vertical “column” shape; develops high-contrast fades. |

| Modern Loose | Cotton/Tencel or Low-Stretch | 11.5 – 12.5 oz | Offers better “drape.” Heavy fabric in a loose cut can feel like “cardboard.” |

Factory Tip: For the 2026 market, Sustainability is no longer optional. We recommend using at least 20% recycled cotton or organic blends. This allows you to market “Eco-Friendly Denim” without significantly increasing your FOB price.

3. The Blueprint: Precise Specs vs. Vague Ideas

Startups often fail during sampling because their tech packs are too vague. Avoid saying “make it loose”; instead, define the Top Block (waist to hip).

Straight Fit Specs:

- Rise: 10.5″ (Mid-rise).

- Knee to Hem: Parallel (No taper).

- Inseam: Offer 30, 32, and 34 to reduce customer tailoring needs.

Loose Fit Specs:

- Rise: 11.5″ (Higher rise to sit comfortably).

- Thigh Ease: +1.5cm to +2.5cm compared to straight fit.

- Leg Shape: “Regular Taper”—wide at the thigh, narrowing slightly to an 18” leg opening.

4. The Sampling Lifecycle: Protecting Your Budget

As a factory, we see startups waste thousands on “endless samples.” To stay lean, follow this 3-Round Protocol:

- Proto Sample (Silhouette Check): Use available “house” fabric. Focus only on the fit and pattern.

- Fit & Wash Sample (The Vision): Use your actual fabric. This is where we apply the “Vintage Wash” or “Dark Rinse.”

- PP Sample (Pre-Production): This is the “Golden Sample.” Everything—labels, stitching color, and hardware—must be 100% perfect.

Warning: Never skip the Wash Test. Denim can shrink up to 5% after the first industrial wash. If your factory doesn’t calculate this “shrinkage allowance” into the pattern, your bulk order will be a size too small.

5. Identifying a Quality Production Partner

For a mid-to-high-end brand, the “lowest price” is usually a red flag. Quality denim requires specialized machinery for heavy seams (like Union Special machines).

Green Flags in a Factory:

- Transparency: They provide a clear cost breakdown (Fabric, CMT, Wash, Trims).

- Technical Proactivity: They suggest changes to your pattern to save fabric or improve durability.

- In-house QC: They follow AQL 2.5 standards for inspection.

Red Flags:

- “Yes-Men”: If a factory says “no problem” to every impossible request without technical questions, they are likely outsourcing your order to a lower-quality workshop.

6. Financial Reality: Landed Costs and Margins

To build a sustainable brand, your gross margin should target 50–65%.

- Estimated FOB (Bulk 500+ pcs): $9.50 – $14.50 (depending on fabric and wash complexity).

- Target Retail: $88 – $168.

- The “Hidden” Cost: Don’t forget to budget for Quality Inspection (QC) and Shipping/Duties, which can add $2–$4 per unit to your landed cost.

Summary for 2026 Launch

The 2026 denim market belongs to brands that prioritize comfort and quality over fast-fashion gimmicks. By anchoring your line in a high-quality Straight fit and capturing trends with a well-engineered Loose fit, you minimize risk and maximize brand loyalty.

Ready to start your 2026 collection?

As a specialized mid-to-high-end denim factory, we help startups translate their designs into production-ready garments. Contact us for a Fabric Swatch Kit and our Standard Fit Block templates.

💡 FAQ: Sourcing Men’s Denim for Startups (2026)

Q1: What is the typical MOQ for a startup brand, and can I mix sizes?

A: As a high-end manufacturer, we understand that startups need to manage inventory risk. Our standard MOQ is typically 200–300 pieces per style/color. Within this quantity, you are free to mix sizes (e.g., a run from size 28 to 38). For long-term partners, we offer even more flexibility based on fabric availability to help you scale your cash flow sustainably.

Q2: Why is the grading logic different for Straight Fit vs. Loose Fit?

A: This is a technical detail many brands miss. Straight fits rely on linear scaling. However, Loose fits require a “Non-Linear Grading” approach. If you simply scale up a loose fit, the larger sizes become overly baggy and lose their premium silhouette. We use digital CAD systems to adjust the hip-to-thigh ratio independently for each size, ensuring the “high-end” look is maintained from the smallest to the largest pair.

Q3: How do you ensure that the bulk production color matches my approved sample?

A: Denim washing is a mix of chemistry and art. To minimize variance, we utilize a “Golden Sample” protocol. Before bulk production begins, we produce 12–24 Pre-Production (PP) Samples. We only proceed with the full order once you have approved the color, hand-feel, and shrinkage of these PP samples. Furthermore, we adhere to AQL 2.5 international inspection standards to ensure consistency across the entire lot.

Q4: Do you offer sustainable or eco-friendly fabric options for the 2026 market?

A: Absolutely. Sustainability is a core requirement for 2026. We offer GRS-certified recycled cotton and BCI (Better Cotton Initiative) blends. Additionally, our laundry facility utilizes Laser whiskering and Ozone bleaching technologies. These methods reduce water consumption by up to 60% and eliminate harsh chemicals, helping your brand meet EU and US environmental import standards.

Q5: What is the lead time from sampling to final delivery?

A: * Sampling: 7–14 days (depending on fabric availability).

- Bulk Production: 20-25 days after the PP sample is approved and the deposit is received. We recommend startups begin the development process at least 2–3 months before their target launch date to allow for marketing and logistics.