For 2026, the men’s denim market is settling into a “Comfort-Performance” era. The skinny jean is dormant; the market is split between two dominant pillars: the Classic Straight (the reliable core) and the Modern Relaxed (the volume driver).

As a specialized high-end denim manufacturer, we know that seeing a trend on a mood board is easy. Executing it in bulk production—where the fit must be consistent across 5,000 pieces—is where the real work happens.

This guide outlines our technical approach to developing these two critical fits for our clients, from global importers to emerging indie brands.

1. The Market Brief: Defining the “New” Standards

Before we cut a single meter of fabric, we align with the buyer on the purpose of the fit. In 2026, “Straight” and “Relaxed” have evolved:

- The 2026 Straight Fit: This is no longer just “Standard.” It’s refined. It features a mid-rise with a mathematically straight line from knee to leg opening. It appeals to the 30-50 demographic who want versatility (office to weekend).

- The 2026 Relaxed Fit: This is not “Baggy.” It is a controlled volume. It offers room in the seat and thigh but typically features a subtle taper to sit correctly on chunky sneakers or boots. It targets the Gen Z and younger Millennial consumer.

Factory Note: For our Private Label clients, we often suggest starting with our proven “Base Blocks” (tested patterns) and tweaking them, rather than starting from zero. This reduces development time by 30%.

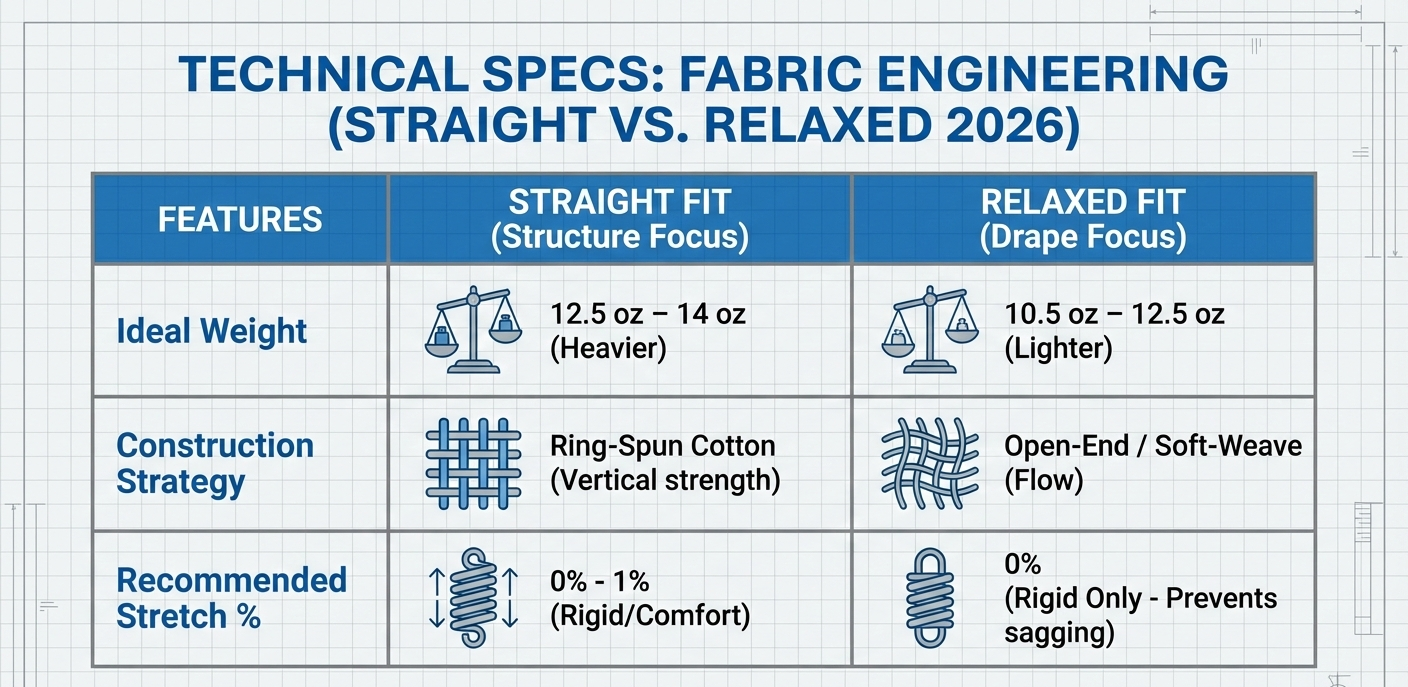

2. Fabric Engineering: Weight & Mechanics

A pattern is only as good as the fabric it’s cut from. Straight and Relaxed fits behave differently and require specific material physics.

| Feature | Straight Fit Requirements | Relaxed Fit Requirements |

| Ideal Weight | 12.5 oz – 14 oz | 10.5 oz – 12.5 oz |

| Construction | Ring-Spun Cotton (for vertical structure). | Open-End or Soft-Weave (for better drape). |

| Stretch % | 0% – 1% (Rigid or Comfort). Too much stretch makes a straight leg look like leggings. | 0% (Rigid). Rigid denim holds the volumetric shape better than stretch. |

| Sourcing Trend | Recycled Cotton blends (GRS Certified) are standard for EU requests. | Hemp blends for a “dry hand” feel are trending in streetwear. |

The Technical Check:

For Straight fits, we test for “Knee Bagging” (recovery). For Relaxed fits, we test for “Torque” (Leg Twist). Because Relaxed jeans use more fabric width, they are prone to twisting after washing if the skewing isn’t controlled at the mill level.

3. Pattern Making: The “Invisible” Details

This is where a quality jeans factory differentiates itself from a budget workshop.

- The Crotch Point: For Relaxed fits, we drop the crotch slightly (0.5 – 1 inch) to increase range of motion. However, if dropped too low, it creates a “diaper effect.” We use CAD to balance the Rise vs. Inseam ratio perfectly.

- The Anti-Flare Straight: A common defect in cheap straight jeans is the optical illusion of a “flare” at the hem. We adjust the inseam pattern by -0.5cm at the knee to ensure the human eye perceives it as perfectly straight.

- Grading (Sizing Up): When scaling a sample size 32 to a bulk size 40, simple math doesn’t work. We apply “Non-Linear Grading.” We add more room to the thigh than the hem to prevent the jeans from looking like stovepipes on larger customers.

4. The Sampling Loop: Validation Before Volume

We move from digital sketches to physical reality through a rigorous 3-stage process.

- Proto Sample (The Rough Draft): Focus on the silhouette. Does the leg fall straight? Does the waist gap?

- Fit Sample (The Reality Check): We fit on real models, not just mannequins.

- The Sit Test: Does the waistband dig in when seated? (Critical for 14oz denim).

- The Shoe Test: Does the leg opening (e.g., 16″) sit correctly over the intended footwear?

- Wash Sample (The Shrinkage Calibrator):

- Crucial Step: We calculate the Shrinkage Rate (e.g., Warp -3%, Weft -1.5%). We must cut the pattern larger than the target specs to account for this. If a factory skips this calculation, your bulk production will be too small.

5. The Wash: Aesthetics Meeting Structure

In 2026, the wash isn’t just about color; it’s about texture.

- For Straight Fits: We recommend “Resin Rinses” or “3D Whisker” lasers. This keeps the look sharp, structured, and premium.

- For Relaxed Fits: We use “Eco-Stone” (enzyme washing) to soften the fabric. A relaxed fit needs to flow; stiff relaxed jeans look cheap.

Sustainability Note: For our import clients targeting the EU/US, we utilize Ozone and Laser technology to reduce water usage, providing the “Green” certification tags your consumers look for.

6. Bulk Production: Ensuring Consistency (QC)

The nightmare for any brand is the “Golden Sample” problem—where the sample is perfect, but the bulk production varies.

Here is how we control it:

- Automated Cutting: We use CNC cutters to ensure every panel is identical to the CAD file.

- Inline Inspection: We check measurements before washing. If the waist is off at the sewing stage, it will be off at the finishing stage.

- AQL 2.5 Standard: We invite third-party inspectors or use our internal team to check finished goods based on strict AQL 2.5 standards (Acceptable Quality Limit).

- Measurements: We guarantee a tolerance of +/- 0.5 inches on critical zones (Waist, Inseam) for rigid denim.

Comparison: Development Timeline

For brands planning their 2026 drops, here is a realistic roadmap:

| Stage | Straight Fit (Core) | Relaxed Fit (Trend) |

| Pattern Dev | 3 Days (Based on existing blocks) | 5-7 Days (Requires drape testing) |

| Sampling | 10-14 Days | 10-14 Days |

| Fit Approval | Fast (Usually 1 round) | Moderate (2 rounds for volume check) |

| Bulk Production | 30-45 Days | 30-45 Days |

Conclusion: Your Supply Chain Partner

Developing the perfect Men’s Straight or Relaxed fit is a balance of Art (Design) and Science (Shrinkage & Torque).

For wholesalers and importers, your factory shouldn’t just be a sewing line; we should be your technical safety net. Whether you are scaling a startup or restocking a classic line, we ensure the fit you approve is the fit your customer receives.

Ready to develop your 2026 collection?

Contact our technical team to request our “2026 Men’s Denim Base Blocks” catalog and start your development with a solid foundation.

Expert Q&A: Manufacturing 2026 Men’s Fits

Q1: What is the main technical difference between the “2026 Relaxed Fit” and a standard “Baggy Jean”?

A: The difference lies in the pattern balance. A standard “Baggy Jean” often just scales up all measurements, looking sloppy. Our “2026 Relaxed Fit” is engineered with a structured top block (waist and hips) to ensure it stays in place, while the thigh and leg opening are widened for drape. We also apply a subtle taper at the hem so the pant legs don’t drag under sneakers, which is a key requirement for modern streetwear brands.

Q2: Does “Relaxed Fit” require more fabric consumption than “Straight Fit”?

A: Yes. A standard Men’s Straight Fit typically consumes 1.35 – 1.45 yards of fabric (depending on width). A Relaxed Fit often pushes consumption to 1.6 – 1.7 yards due to wider panels and lower marker efficiency. Buyers should expect a 10-15% increase in fabric cost for relaxed styles compared to core straight fits.

Q3: How do you prevent leg twisting (torque) on wide/relaxed jeans?

A: Leg twist is the #1 defect in loose-fitting denim. We mitigate this by:

- Using skewed denim fabric right from the mill.

- Adjusting the pattern’s inseam angle to counteract the natural torque of the twill weave.

- Performing a wash test on the first 50 pieces. If the side seam twists more than 3/4 inch (2cm), we reject the lot.

Q4: Can I use the same 14oz rigid fabric for both fits?

A: You can, but we advise caution.

- For Straight Fits: 14oz Rigid is perfect; it creates that classic, premium “cardboard” look.

- For Relaxed Fits: 14oz can be too heavy and stiff, causing the fabric to “tent” (stick out) rather than drape naturally. We recommend stepping down to 12oz – 12.5oz or using a fabric with a “Soft Finish” treatment to ensure the relaxed silhouette flows correctly.