Women’s wide leg jeans and straight leg jeans are the twin pillars of the 2026 denim market. For women’s fashion brands, boutique labels, and denim importers, these styles represent a massive revenue opportunity—but only if the production execution is flawless.

On trend reports, the shift looks simple: “Make the legs wider.” However, in the factory, this shift creates complex challenges in pattern balance, fabric drape, and consumption costs. Sourcing these styles for jeans wholesale or bulk orders often fails not because of bad design, but because of poor technical briefs and overlooked testing.

Drawing from our experience as a specialized women jeans factory, here is a breakdown of the most common mistakes B2B buyers make—and how to fix them before you lose money on a bad shipment.

1. Are You Chasing Social Media “Hype” Instead of Your Customer’s Reality?

The first mistake private label startups make is confusing “Instagram Trends” with “Commercial Reality.”

The Mistake: Seeing ultra-wide, floor-sweeping wide leg jeans on TikTok and ordering that exact exaggerated silhouette for a mass-market audience. Or, completely cutting straight leg jeans from the order to bet 100% on wide fits.

The Reality: While Gen Z might wear puddle-hem wide legs, the core customer for most boutique labels (women aged 28-45) often finds them impractical for office or daily wear. Over-indexing on extreme trends leads to high stock levels of unsold goods.

How a Good Factory Helps: A strategic denim manufacturer will analyze your brand positioning before cutting the fabric:

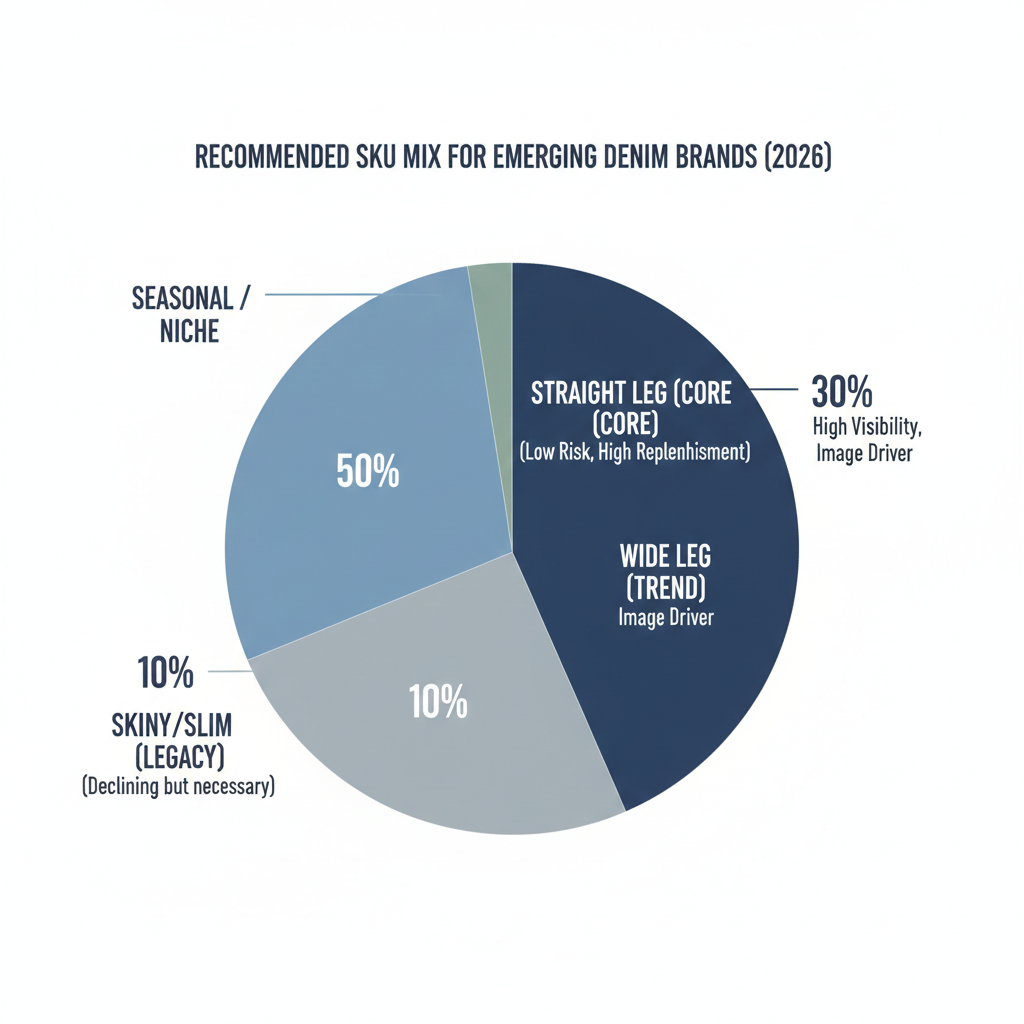

- The Mix Strategy: We recommend keeping straight leg jeans as your “Bread and Butter” (the safe, high-volume core) and using wide leg jeans as your “Brand Builder” (the trendy, high-margin item).

- The Adjustment: We can modify a runway trend into a “Commercial Fit”—for example, reducing a 24-inch leg opening to a wearable 21 inches for better sell-through.

📊 Visual Insight: The Ideal Inventory Mix

2. Are Your Fit Briefs Too Vague for Complex Silhouettes?

“High waist, wide leg, looks like this photo.” — This is the most dangerous brief a buyer can send for a jeans bulk order.

The Mistake: Wide leg jeans rely on architecture, not stretch, to fit. If you don’t specify the “Rise curve” or the “Thigh-to-Hip ratio,” the jeans will gap at the waist or bunch at the crotch. For straight leg jeans, a vague brief often results in a leg that is accidentally tapered (looking like a loose skinny jean) or slightly flared.

The Solution: Stop relying on photos. Start relying on specs. A professional women’s jeans manufacturer will require:

- For Wide Leg: Focus on the “Top Block.” The waist must be secure to support the heavy fabric of the legs. We also need to define the “break point” at the shoe to prevent tripping hazards.

- For Straight Leg: The “Knee Measurement” is critical. It must be perfectly calibrated so the line from knee to hem is mathematically straight.

3. Are You Treating Fabric Selection as an Afterthought?

Fabric choice is the #1 reason for high return rates in e-commerce.

The Mistake:

- Wide Leg Error: Choosing a heavy, rigid 14oz denim. Result: The jeans feel like cardboard, rustle loudly when walking, and make the wearer look wider than they are.

- Straight Leg Error: Choosing a thin, high-stretch (40%+) fabric. Result: The “Straight” shape collapses after two hours of wear, looking like leggings.

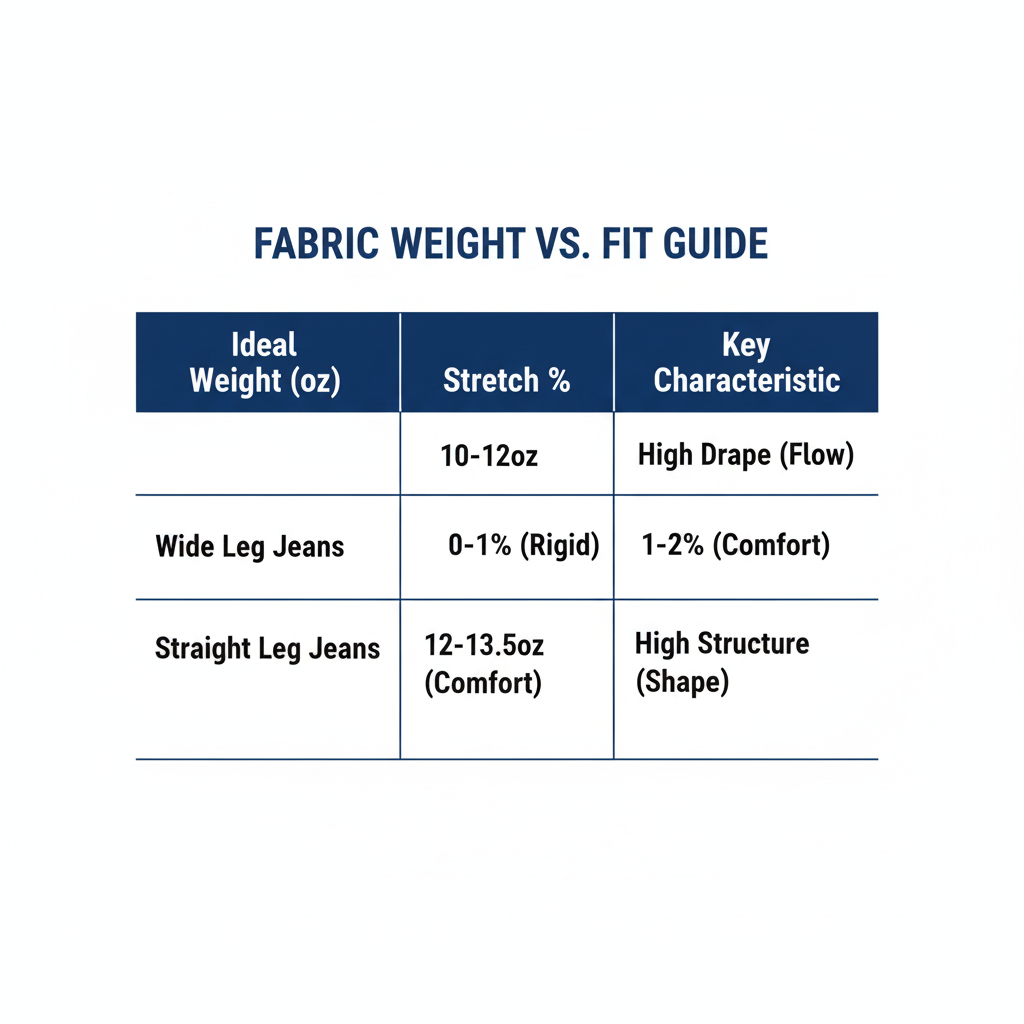

The Factory Standard: We guide denim importers toward specific weights for specific cuts:

- Wide Leg: Needs “Drape.” We suggest 11oz – 12.5oz mid-weight denim. If you want comfort, use low-stretch (1% elastane) or “Comfort Rigid” technology.

- Straight Leg: Needs “Structure.” We suggest 12oz – 13.5oz. It needs enough weight to hold the vertical column shape.

📊 Visual Insight: Fabric Weight vs. Fit Guide

4. Are You Skipping Wear Tests Before Bulk Orders?

Samples often look perfect on a standing mannequin. But real life involves sitting, squatting, and climbing stairs.

The Mistake: Approving a bulk order based on a size 26 sample worn by a professional model for 5 minutes. This fails to reveal how wide leg jeans might drag on the floor when switching from heels to sneakers, or how straight leg jeans might twist (leg torque) after washing.

The Solution: Reliable factories enforce a “Dynamic Fit Session”:

- Movement Testing: We ask: Does the waist gap when the model sits? (Common in wide legs). Does the knee tight point restrict movement?

- Size Set Run: Do not just test the sample size. We recommend testing a Size 26, 29, and 31 to ensure the grading (sizing up) maintains the silhouette’s integrity across the range.

5. Are You Picking Factories Based Only on the Lowest Quote?

New private label startups often filter suppliers by “Lowest Price,” not realizing that price reflects capability.

The Mistake: Assuming a low quote covers the complexity of modern denim. Cheap factories often cut costs by:

- Using “Open End” (cheaper, rougher) cotton instead of “Ring Spun.”

- Skipping the “Anti-Torque” skewing process (causing twisted legs).

- Reducing stitch count per inch (causing seams to burst).

The Cost Breakdown: A transparent jeans wholesale manufacturer explains where your money goes:

- Fabric: 45-50% of the cost.

- Washing/Finish: 20-30% (Critical for the vintage look).

- Labor & Trims: 20%.

- Margin: 10-15%. Warning: If a quote is 30% lower than market average, they are likely swapping your fabric for a lower grade.

6. Are You Overlooking MOQs, Lead Times, and Real Capacity?

Great designs fail when they miss the selling season.

The Mistake: Designing a collection with 10 different colors but only ordering 100 pieces per color. Most mills have a minimum fabric booking. Also, expecting a 4-week turnaround for bulk during peak season (Pre-Holiday) is a recipe for disaster.

The Expectation:

- MOQ Strategy: Instead of 10 colors, pick 2 core washes (Light Blue, Vintage Indigo) and consolidate your volume to hit factory MOQs (e.g., 300 pcs/style).

- Timeline: Proto sample (7-10 days) -> Fit/Wash Approval (14 days) -> Production (30-45 days) -> Shipping. Plan 3 months ahead.

7. Are You Relying on Verbal Agreements Instead of Written Standards?

“Make it good quality” is not a contract.

The Mistake: No technical packs, no “Golden Sample” (sealed counter sample), and no agreed Defect Rates (AQL). When the shipment arrives with minor color variance, you have no grounds to claim compensation.

The Protection: Professional women jeans factories formalize the standard:

- Golden Sample: We sign and seal one pair of jeans that represents the exact color and handfeel of the bulk. If production deviates, this is the judge.

- AQL 2.5: We adhere to the Acceptable Quality Limit standard used by major global brands.

- Wash Tolerance: We agree on a “Shade Band” (Light limit, Standard, Dark limit) because denim washing naturally varies slightly.

Conclusion: Turning Sourcing into a Science

For denim importers and indie brands, avoiding these seven mistakes changes the game. It turns women’s wide leg jeans and straight leg jeans from a risky gamble into a reliable profit engine.

A capable factory doesn’t just sew fabric; they act as your technical consultant. They translate your trend concepts into wearable, durable, and profitable products.

💡 Expert Q&A: Sourcing Technicals

Q1: What is the best fabric weight for women’s wide leg jeans?

A: For the 2026 market, the ideal fabric weight for women’s wide leg jeans is between 10.5oz and 12.5oz.

- Why: Unlike skinny jeans, wide leg styles rely on “drape” (how the fabric falls).

- Risk: If you use heavyweight denim (14oz+), the jeans will feel stiff, bulky, and uncomfortable at the waist. If you use lightweight denim (under 10oz), they will look like “pajama pants” and lack the premium structure buyers expect.

- Recommendation: Choose a 100% Cotton Rigid or 99/1 Comfort Stretch in the 11-12oz range for the best balance of structure and flow.

Q2: Why do wide leg jeans cost more to manufacture than straight leg jeans?

A: Wide leg jeans typically have a 15-25% higher FOB cost due to three factors:

- Fabric Consumption: A standard straight leg jean uses approx. 1.2 meters of fabric. A wide leg jean uses 1.5 to 1.7 meters.

- Marker Efficiency (Waste): Wide patterns create more “dead space” between pieces on the cutting table, leading to higher fabric wastage.

- Washing Labor: The larger surface area requires more chemicals and longer handling times during hand-sanding or laser treatments to achieve a vintage look.

Q3: How do I ensure quality control (QC) for denim bulk orders?

A: Never rely on visual checks alone. Professional buyers use the AQL 2.5 Standard (Acceptable Quality Limit). Your QC checklist should include:

- Measurement Check: Measure critical points (Waist, Hips, Thigh, Inseam) against the Tech Pack tolerances (+/- 0.5cm).

- Shade Banding: Compare bulk washes against 3 approved shades (Light, Medium, Dark tolerances) to ensure consistency.

- Torque Test: Check for “Leg Twist” after washing. If the side seam twists more than 2.5cm to the front, it is a defect.

- Fitting Test: Try random samples on a live model to check for “Waist Gaping” (a common issue in wide leg fits).

Q4: What is the difference between buying from a Trader vs. a direct Jeans Factory?

A:

- Trader (Middleman): Often has lower MOQs but adds a 15-30% margin on top of the factory price. Communication is slower because they must relay messages to the actual manufacturer. You have less control over production delays.

- Direct Factory (Manufacturer): Offers the lowest factory-direct price and full transparency on the production line. You can speak directly to technical managers about fit issues. However, factories may require clearer technical briefs and established MOQs (e.g., 300pcs/style).

- Best for you: If you are a growing private label or importer, working directly with a factory secures better margins and consistent quality for the long term.