Executive Summary: The “Indigo Fatigue”

Retail data for Q4 2025 indicated a significant shift: while Indigo remains the volume driver, Non-Blue Denim accounted for the highest growth in the “Premium” price bracket.

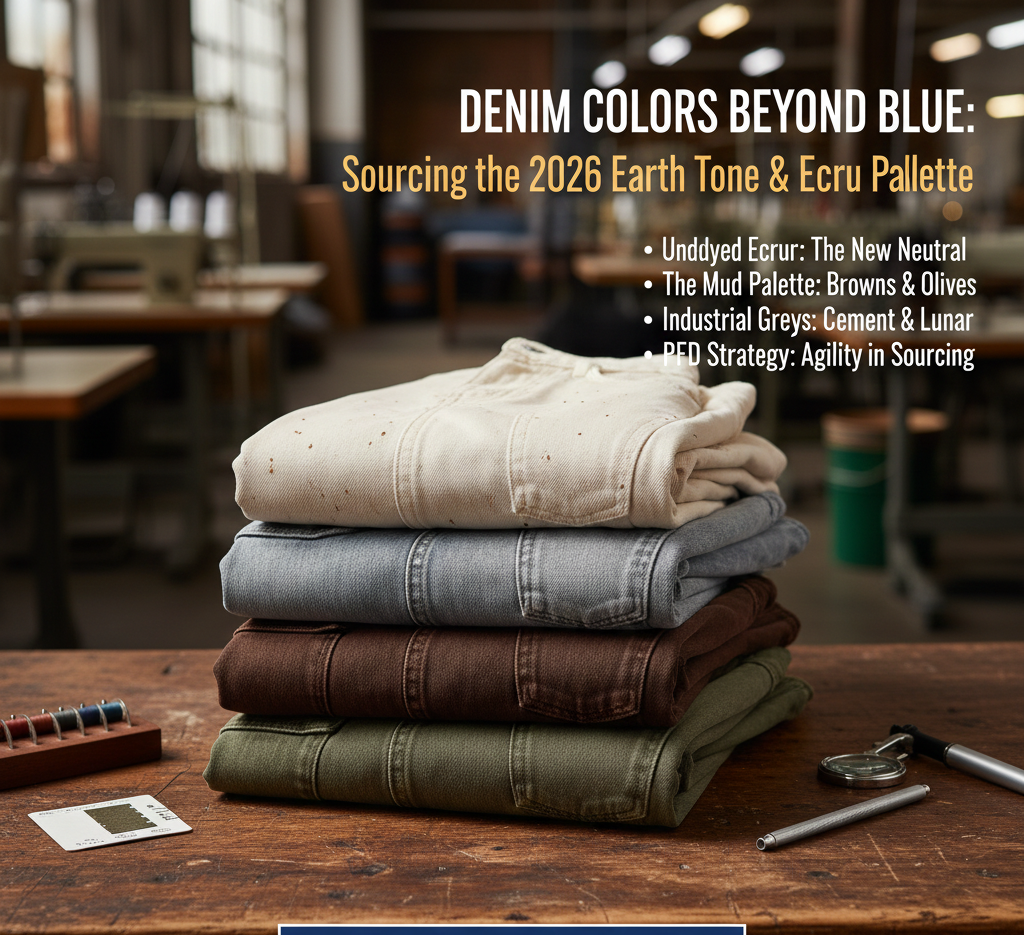

For 2026, the male consumer is looking for versatility. They want the durability of denim but the color palette of chinos. This report outlines the three dominant color families you must secure capacity for: Undyed (Ecru), The Mud Palette (Browns/Olives), and Industrial Greys.

1. The Hero SKU: Undyed / Ecru (Natural)

“White jeans” are scary for men. Ecru is essential.

- The Trend: Driven by the “Old Money” and “Sustainable” narratives. It implies a lack of chemical processing.

- The Look: It must be seeded, meaning you can see the tiny brown cotton husk specks in the fabric. It should not be bleached bright white.

- Sourcing Spec: Request “Unbleached / Scoured Only” bull denim.

- Weight: 13oz – 14oz. Ecru can be transparent if too light. It needs density to look masculine.

2. The “Mud” Palette: Chocolate & Olive

The “Gorpcore” (outdoor/hiking) influence has made brown the new black.

- The Colors: Bitter Chocolate, Tobacco, and Desaturated Olive.

- The Technique (Buyer’s Choice):

- Volume Route: Reactive Piece Dye. Dye the finished garment for consistent, flat color. Cheaper, cleaner.

- Premium Route: Sulfur Dye + Stone Wash. Creates a “faded vintage” look where the seams turn white/grey. This is the trending “Carhartt/Workwear” aesthetic.

- Merchandising: These colors sell best in Utility/Carpenter fits, not 5-pocket styles.

3. Industrial Grey: “Cement” & “Lunar”

Black jeans are standard, but 2026 sees a move toward lighter, chalkier greys.

- The Look: “Cement” (a warm, light grey) and “Lunar Rock” (a cool, mid-grey).

- The Application: These shades replace the standard “Stonewash Blue” for the modern office. They pair better with black t-shirts than blue jeans do.

- Sourcing Tip: Use Black warp / White weft fabric and wash it down heavily with enzymes. Do not simply dye white fabric grey—it looks flat and cheap. You need the “grain” of the denim to show through.

4. Strategic Sourcing: The PFD (Prepared for Dye) Strategy

Unsure which color will pop in Q3 2026? Don’t commit to colored fabric rolls yet.

- The Strategy: Buy 5,000 yards of PFD (Prepared for Dye) Bull Denim in a neutral 13oz weight.

- The Benefit: You sew the inventory in raw/white. As sales data comes in from early drops, you can send batches to the dye house to be Garment Dyed in the winning colors (e.g., if Brown is outselling Olive, dye more Brown).

- Lead Time: Reduces reaction time from 3 months (fabric production) to 3 weeks (dyeing).

FAQ: Non-Indigo Sourcing

Q: What is the difference between Bull Denim and Regular Denim?

A: Regular Denim is a twill weave (3×1) with a colored warp and white weft. Bull Denim is a 3×1 twill where both yarns are the same color (usually natural/ecru). Bull denim is preferred for piece-dyeing (creating solid colors like brown or green) because it results in a more uniform, saturated color than regular denim.

Q: Why is “Ecru” trending for men in 2026?

A: Ecru serves as a bridge between formal trousers and casual jeans. It allows men to wear a rugged fabric (denim) in a color that feels appropriate for “Summer Business Casual.” It also aligns with the Sustainability demand for less water-intensive dyeing processes.

Q: How do you prevent color fading in garment-dyed jeans?

A: To improve color fastness in garment-dyed denim, buyers should specify Reactive Dyes rather than Pigment Dyes. While Pigment Dyes offer a cool “vintage” look, they wash out quickly. Reactive Dyes chemically bond with the cotton fiber, retaining the deep Chocolate or Olive tones for 50+ washes.