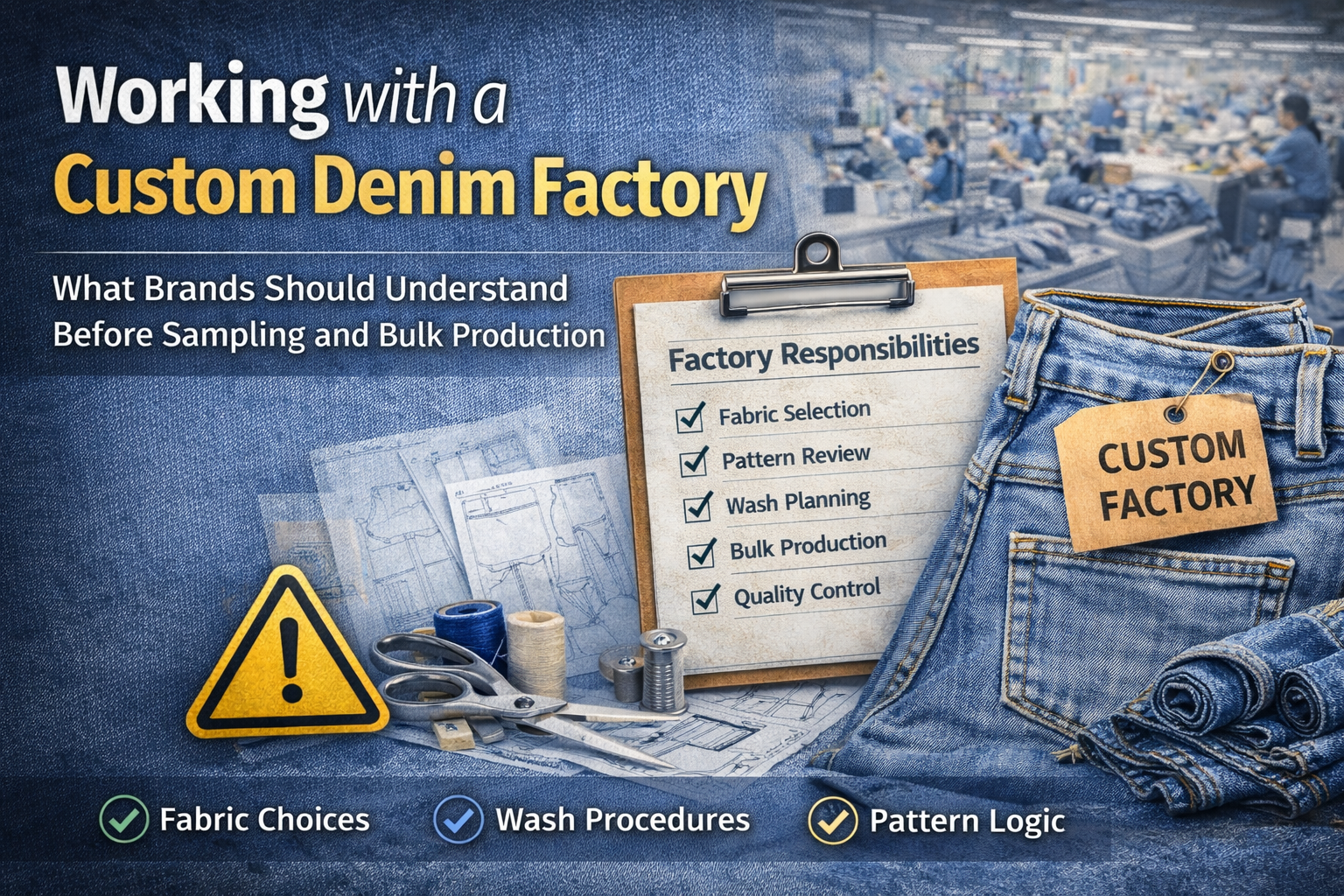

What Brands Should Understand Before Sampling and Bulk Production

Working with a custom denim factory is rarely just about placing an order.

For most brands, the real challenge starts after the first tech pack is sent.

Denim is not a plug-and-play product. Fabric behavior, washing impact, pattern logic, and production rhythm all affect the final result. When communication is unclear or expectations are misaligned, even experienced brands can run into delays, fit issues, or cost overruns.

This page focuses on how custom denim factories actually work, how decisions are made on the factory side, and how brands can build a smoother, more predictable working relationship.

What does a custom denim factory actually handle?

Many brands assume a denim factory mainly “sews jeans.”

In reality, production is only one part of the work.

A typical custom denim factory is involved in:

- Fabric selection and feasibility checks

- Pattern review and fit risk assessment

- Sampling coordination and revision planning

- Washing method selection and test runs

- Bulk production planning and quality control

- Risk management when materials or timelines change

Understanding this broader role helps brands ask better questions and avoid unrealistic expectations early in the process.

When should a brand start talking to a denim factory?

One common mistake is contacting factories only after everything feels “final.”

From a factory perspective, the best timing is earlier than most brands expect.

Early involvement allows factories to:

- Flag fabric or wash risks before sampling

- Adjust patterns based on fabric behavior

- Suggest alternative materials with more stable supply

- Estimate realistic MOQ and lead time ranges

Waiting too long often leads to rework, higher costs, or sampling delays.

How do factories evaluate a new denim project?

When a factory receives an inquiry, the internal review usually focuses on:

- Fabric type and availability

- Wash complexity and risk level

- Pattern difficulty and grading logic

- Target quantity and size breakdown

- Timeline expectations

Projects with unclear direction or unrealistic deadlines often require more clarification before sampling can even begin.

Clear communication at this stage builds trust and speeds up development.

Why fabric decisions matter more than most brands expect

Fabric choice influences almost every downstream step.

From a factory point of view, fabric affects:

- Pattern tolerance

- Wash stability

- Fit consistency between sampling and bulk

- Yield and cutting efficiency

- Quality control standards

Two fabrics with similar weights or stretch percentages can behave very differently during washing and wear. This is why factories often request wash tests or alternative fabric options before confirming bulk feasibility.

How sampling really works inside a denim factory

Sampling is not a straight line.

A typical flow looks like:

- Pattern review and adjustment

- First sample cut and sewn

- Wash testing and measurement check

- Fit feedback and pattern revision

- Second or third sample if needed

Factories expect changes during sampling. What matters is how those changes are managed.

Clear, prioritized feedback helps factories respond faster and avoid unnecessary revisions.

What factories need from brands during sampling

From the factory side, smooth sampling depends on:

- Clear fit priorities (what matters most, what is flexible)

- Consistent measurement standards

- One consolidated feedback channel

- Realistic expectations about wash variation

Conflicting feedback or frequent direction changes increase both time and cost.

How washing decisions affect factory planning

Washing is one of the highest-risk stages in denim production.

Factories must consider:

- Fabric shrinkage and recovery

- Color consistency

- Damage risk to stretch fibers

- Wash capacity and scheduling

Heavy vintage washes require more testing and tighter control. Factories often recommend stabilizing fit before adding aggressive wash effects.

Understanding MOQ from a factory perspective

MOQ is rarely an arbitrary number.

It is shaped by:

- Fabric mill minimums

- Dye lot requirements

- Wash batch efficiency

- Cutting and sewing line setup

- Quality control costs

When brands understand these factors, MOQ discussions become problem-solving conversations rather than price disputes.

How factories plan bulk production after sampling

Once sampling is approved, factories shift focus to stability.

Key checks include:

- Final fabric batch confirmation

- Pattern locking

- Wash standard setting

- Size grading verification

- QC checkpoints definition

Skipping or rushing these steps increases the risk of bulk inconsistency.

What quality control looks like in denim manufacturing

Quality control in denim is layered.

Factories typically monitor:

- Fabric inspection before cutting

- Measurement checks during sewing

- Wash consistency audits

- Final garment inspection

Brands that align their expectations with factory QC processes see fewer surprises at shipment.

Why communication style matters more than frequency

Daily messages do not guarantee clarity.

Factories respond best to:

- Structured feedback

- Clear priorities

- Realistic timelines

- Respect for production constraints

A calm, solution-oriented approach builds long-term reliability.

Common misunderstandings between brands and factories

From factory experience, the most common issues include:

- Assuming sampling guarantees bulk behavior

- Expecting stretch denim to fix fit problems

- Underestimating wash impact

- Changing direction mid-production

- Treating MOQ as negotiable without trade-offs

Recognizing these early helps prevent costly mistakes.

How long-term factory partnerships are built

Strong factory relationships develop over time.

Brands that succeed long-term tend to:

- Start with manageable styles

- Build trust before scaling

- Share realistic sales forecasts

- Accept gradual improvement instead of perfection

Factories invest more effort when projects show stability and growth potential.

When switching factories makes sense — and when it doesn’t

Not every issue requires a factory change.

Switching may help when:

- Core capabilities don’t match your product

- Communication consistently breaks down

- Quality systems are unreliable

But many problems come from unclear development planning rather than factory performance.

Final thoughts from the factory side

Working with a custom denim factory is a process, not a transaction.

The brands that achieve consistent quality and predictable production are not those with the lowest costs, but those who understand how denim manufacturing really works and plan accordingly.

Clear decisions, realistic expectations, and steady collaboration reduce risk for both sides.