Tech & Pattern Making: The Engineering Behind the Fit

In denim production, a pattern is more than a design template—it is a technical blueprint that must account for the unpredictable nature of fabric shrinkage and industrial washing. At Xinen Garment, our pattern-making process is grounded in physical testing and iterative refinement. We focus on creating a stable foundation so that the fit you approve in the sampling stage remains predictable during bulk production.

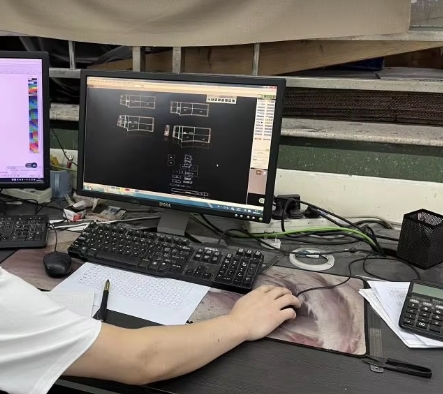

Technical Drafting & Shrinkage Compensation

Denim is unique because it is cut “large” and washed “small.” A pattern that ignores the specific shrinkage of a fabric lot is a liability.

- Batch-Specific Adjustment: We don’t use universal templates. For every new project, we test the fabric’s warp and weft shrinkage first, then calculate the “shrinkage factor” into the CAD pattern before cutting the initial sample.

- Accounting for Wash Intensity: A heavy stone wash shrinks fabric differently than a light enzyme wash. Our technicians adjust the rise, inseam, and waistband measurements based on the intended Denim Washing & Finishing process to ensure the final garment hits the spec sheet.

Fit Development & Iterative Sampling

Fit is rarely perfected in a single round. It is an evolutionary process that requires clear feedback and precise pattern adjustments.

- The Prototype Phase: We translate your Tech Pack or reference sample into a digital pattern. The first sample (Fit Sample) is used to evaluate the balance of the garment—checking the hip-to-waist ratio, the seat curve, and the drape of the leg.

- Systematic Revisions: When fit comments are received, we don’t just “move a line.” We analyze how an adjustment in the front rise affects the back balance. We document every revision to ensure that each sample iteration is a measurable improvement over the last.

- Standard Tolerances: We work within the industry-standard tolerance of +/- 2cm. Our goal is to maintain this consistency across the entire production run through rigorous Quality Control.

Grading & Size Range Integrity

Scaling a pattern from a base size (e.g., Size 32) to a full size range requires more than simple mathematical increments.

- Proportional Grading: As sizes increase, body proportions change. We adjust our grading logic to ensure that larger sizes don’t lose their intended silhouette or comfort, particularly in the thigh and rise areas.

- Plus-Size Logic: For plus-size development, we re-evaluate the rise curvature and pocket placement to maintain visual balance and prevent the waistband from gaping or pulling.

Managing Pattern Consistency for Repeat Orders

For established brands, the value of a factory lies in its “memory.”

- Stable Fit Identity: Once a fit is approved and produced, we lock that pattern logic. When you return for a restock or a new colorway using the same Denim Fabric Innovation, we utilize the established fit data to minimize development time and ensure your customers get the same fit every season.

- Digital Pattern Archiving: All patterns are managed in our CAD system, ensuring that even years later, the base fit of your core styles remains accessible and accurate.

Technical Integration

A pattern cannot exist in isolation. Its success depends on the synergy between the sewing room and the laundry. By integrating technical pattern making with real-world manufacturing constraints, we help brands transition from a creative concept to a repeatable, commercial product.