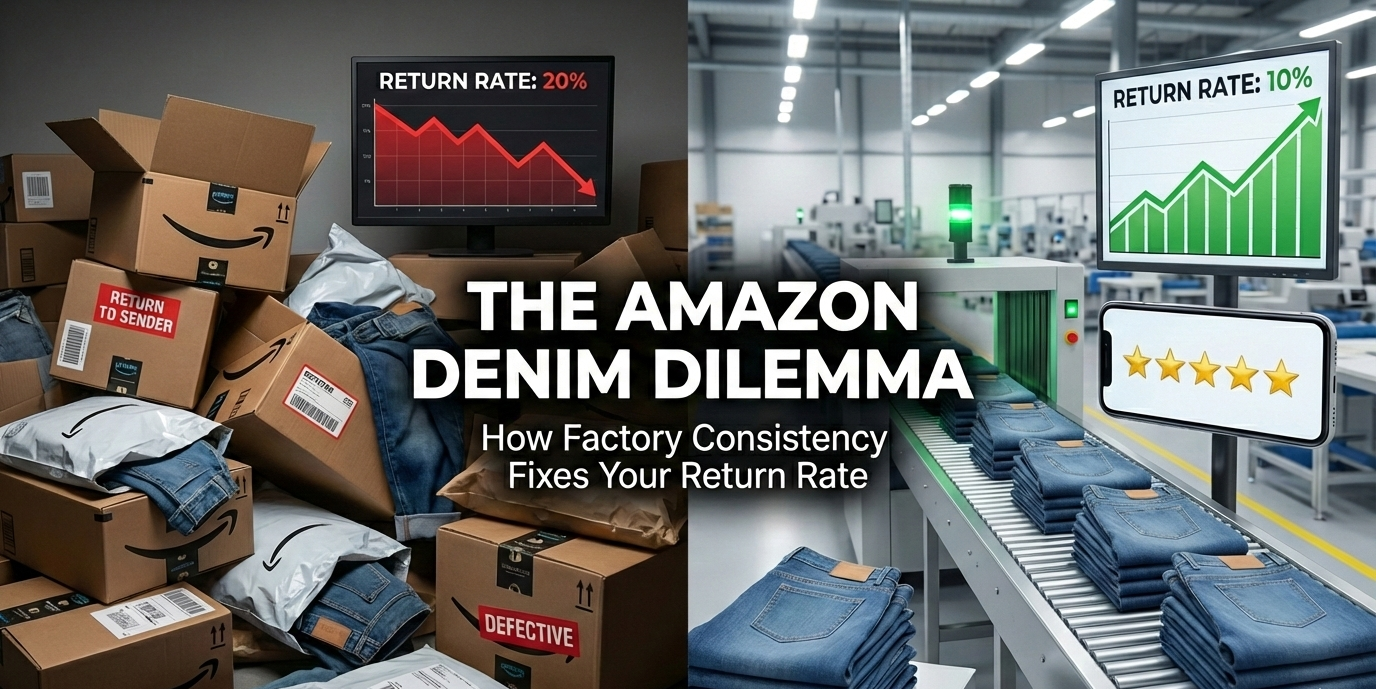

If you sell apparel on Amazon, you already know the “Return Dissatisfaction Rate.” But in the denim category, the numbers are often brutal. You might have a great-looking pair of jeans, a perfect listing, and strong sales—only to find that 20% or even 25% of your orders are coming back.

Most of these returns are tagged with a few familiar reasons: “Too small,” “Inconsistent fit,” or “Doesn’t look like the photo.”

For an Amazon seller, a return isn’t just a lost sale. You lose the FBA fulfillment fee, you pay a return processing fee, and most importantly, your listing’s “Quality Health” takes a hit. If the return rate stays too high, Amazon will suppress your buy box or even suspend the listing.

The truth is, many sellers blame the customers for being “picky.” But as a denim manufacturer, we know the truth: High return rates are usually a factory problem, not a customer problem. In denim, consistency is incredibly hard to achieve. If your factory isn’t obsessed with the technical details of fabric and washing, your Amazon business will suffer.

Why is the return rate for jeans on Amazon so much higher than other clothing categories?

Denim is a unique beast. Unlike a polyester t-shirt or a nylon legging, denim is made of cotton (often mixed with spandex). Cotton is a natural fiber that is “alive.” It reacts to heat, water, and tension.

The biggest reason for returns on Amazon is Size Inconsistency. A customer might buy your “Slim Fit Size 32” in January and love it. They come back in June to buy the same pair, but this time it’s too tight. They return it and leave a 1-star review.

Why did this happen? It’s because denim goes through a violent process called “Industrial Washing.” Jeans are sewn “raw” (oversized) and then washed in giant machines to reach the final color and softness. If the factory doesn’t calculate the “Shrinkage Ratio” perfectly for every single batch of fabric, the final measurements will be different every time.

How does fabric inconsistency at the factory lead to “it doesn’t fit” reviews?

When you order 1,000 pairs of jeans, the factory buys fabric in “rolls.” Even if the fabric is the same 12oz denim from the same supplier, Roll A might have a slightly different stretch or shrinkage than Roll B.

In a low-quality factory, they use the same “Master Pattern” for every roll of fabric. They cut the fabric, sew it, and wash it all the same way. The result?

- Roll A shrinks 3%—The jeans come out perfect.

- Roll B shrinks 5%—The jeans come out half a size too small.

On Amazon, “half a size too small” is an automatic return.

How we solve this: At Xinen Garment, we don’t assume every roll is the same. We perform a Batch Shrinkage Test. Before cutting the fabric, we take a 1-meter square of the material from each batch, wash it in our industrial machines, and measure exactly how much it shrinks in both width and length. We then adjust the digital pattern for that specific batch to compensate. This ensures the final Size 32 is always a Size 32.

Can a factory actually control denim shrinkage to prevent sizing surprises?

Controlling shrinkage is the difference between a “professional factory” and a “cheap workshop.” To keep your Amazon return rate low, the factory must follow a rigid technical process.

Here is how the logic works during production to ensure consistency:

| Production Step | The “Lazy” Way (High Returns) | The Xinen Way (Low Returns) |

| Fabric Arrival | Start cutting immediately. | Perform “Point-4” inspection and Shrinkage Test for every lot. |

| Pattern Making | Use one standard pattern for all fabrics. | Use “Adjusted Patterns” based on specific batch shrinkage data. |

| Sewing | Focus only on speed. | Use specialized “Gauge” tools to ensure seam allowances are identical. |

| Washing | Throw everything in the machine together. | Controlled “Load Weights” and timed chemical cycles for uniform results. |

| Post-Wash QC | Visual check only. | Measurement Check: Every pair is measured against the spec sheet after drying. |

If you skip the shrinkage adjustment, you are essentially gambling with your Amazon account health.

Why do “color and wash differences” trigger so many Amazon returns?

The second most common reason for returns is: “The color looks different from the listing photos.”

In denim, the color is created in the laundry. This is a chemical process involving enzymes, stones, and bleach. If the water temperature is 5 degrees higher today than it was yesterday, or if the “stones” in the machine are newer and more abrasive, the jeans will look different.

If an Amazon customer buys a “Medium Blue” jean but receives something that looks like “Light Blue,” they feel cheated.

The Consistency Fix: We use “Wash Recipes.” Every custom project we handle has a documented formula—the exact temperature of the water, the exact grams of enzymes used, and the exact minute-by-minute cycle time. We also keep a “Master Sample” from your first production run. During the second and third runs, our QC team compares the new batch to the Master Sample under professional D65 lighting to ensure the shade is within the acceptable 5% tolerance.

What role does final quality control play in protecting your Amazon Seller Account?

Amazon buyers are notoriously picky. Unlike a customer in a physical store who might overlook a loose thread, an Amazon buyer will take a macro photo of it and open a “Product Defective” return.

Too many “Defective” flags will trigger an internal audit of your account by Amazon.

Our final QC line focuses on the “small” things that cause big headaches for sellers:

- The Zipper Test: We pull every zipper three times. A stuck zipper is a guaranteed return.

- Loose Threads: We employ dedicated “trimmers” who clean every seam.

- Hardware Strength: We test the rivets and buttons to ensure they don’t pop off.

- Odor Control: Many factories use cheap chemicals that leave a “sulfur” smell. We use high-grade neutralizers so the customer doesn’t smell “chemicals” when they open the bag.

How can choosing the right manufacturing partner turn a 25% return rate into 10%?

Reducing your return rate from 25% to 10% can literally double your net profit on a product.

When you work with a factory that understands the Amazon ecosystem, you aren’t just buying pants; you are buying Account Security. We realize that for an FBA seller, the “Product” is actually the Review Star Rating.

By focusing on “Production Consistency”—ensuring the 1,000th pair is identical to the 1st pair—we help you build a “staple product.” This is a product that gets 4.5-star reviews consistently, which allows you to spend less on PPC and more on scaling your brand.

Conclusion: Stop Fighting the Returns, Fix the Source

If your Amazon return rate is over 20%, you don’t need a better “Size Chart” in your images (though that helps). You need a more consistent production line.

At Xinen Garment, we specialize in helping Amazon and E-commerce brands stabilize their supply chains. We understand that in the world of FBA, a “Cheap” jean that fits poorly is actually very expensive in the long run. We focus on the technical side—the shrinkage tests, the wash recipes, and the rigid QC—so you can focus on ranking and selling.

FAQ: Common Concerns for Amazon Denim Sellers

Here are some of the most frequent questions we receive from Amazon sellers who are struggling with their return metrics and inventory health.

Why do some of my black jeans have a “chemical smell” while others don’t?

This is a common complaint in Amazon reviews. Most black denim is dyed using sulfur. If a factory is rushing the production or using low-grade chemicals to save costs, the sulfur isn’t properly neutralized during the wash. At Xinen Garment, we use high-quality neutralizing agents and an extra “softener wash” cycle for all black denim to ensure your customers smell nothing but fresh fabric when they open the package.

Is a 15% return rate “normal” for denim on Amazon?

In the apparel category, anything under 15% for denim is considered excellent. Because denim has no “stretch” in some styles and high “stretch” in others, customers often order two sizes and return one. However, if your rate climbs above 20-25%, it usually means there is a systematic sizing error in your production line that needs to be fixed at the pattern level.

Can I just use a “standard” size chart from a famous brand?

We strongly advise against this. Every brand’s size chart is calibrated to their specific fabric’s elasticity and shrinkage. If you copy a Levi’s chart but use a fabric with more spandex, your jeans will feel “too big” for the customer. We recommend creating a Custom Size Chart based on a physical “Size Set” (samples of every size) produced by the factory.

How does the factory ensure the jeans don’t “twist” after the customer washes them?

“Leg twisting” (where the side seam moves to the front of the leg) is a major reason for quality complaints. This happens when the fabric isn’t properly “Skewed” or leveled before cutting. Our cutting team ensures the fabric grain line is perfectly aligned with the pattern. It takes a little more time, but it prevents your jeans from looking “cheap” after the first home wash.

Does “Eco-friendly” washing affect the consistency of the color?

Actually, modern eco-friendly methods like Ozone Washing are often more consistent than traditional bleach. Because ozone machines are computer-controlled, they deliver the exact same amount of “fading” to every batch. It reduces the human error involved in manual chemical mixing, which helps keep your Amazon photos looking exactly like the product the customer receives.