The “Jorts” Reality: It’s Not Just a Longer Short

The resurgence of the “Jort” (Jean Short) – specifically the baggy, below-the-knee silhouette – presents a specific set of challenges for mass production. For brands, the appeal is aesthetic. For us as manufacturers, the reality is consumption.

A standard slim-fit denim short might consume 0.6–0.7 meters of fabric. A baggy, carpenter-style Jort with a 12-inch inseam and wide leg opening can easily push consumption over 1.0–1.2 meters. In a wholesale order of 5,000 units, that difference significantly impacts the FOB price.

Here is how we approach the manufacturing of baggy denim shorts to balance the “oversized” look with production efficiency.

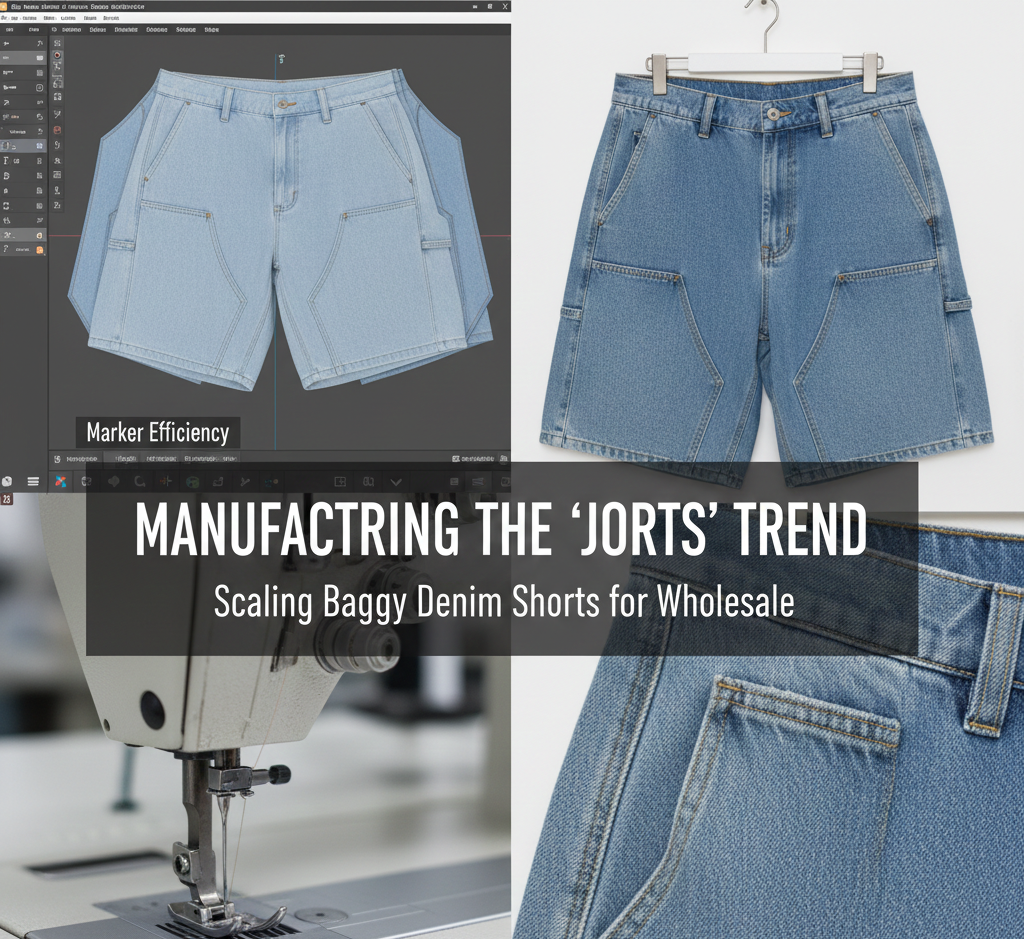

1. Marker Efficiency & Fabric Width Strategy

The biggest hidden cost in manufacturing baggy shorts is fabric waste. Because the pattern pieces are wide and boxy, they don’t always “nest” tightly together in the marker, leading to higher wastage between panels.

- Our Approach: When we receive a Jorts tech pack, our first step is Marker Simulation. We analyze the pattern width against standard fabric roll widths (typically 58/60″).

- The Adjustment: Sometimes, reducing the hem width by just 1cm allow us to fit an extra leg panel into the marker width, saving up to 5% fabric usage without visibly changing the garment’s silhouette. We communicate these efficiency options to our clients before cutting.

2. Engineering the “Baggy” Fit (Without the Sag)

“Baggy” does not mean “shapeless.” A common issue with low-quality Jorts is that they rely solely on sizing up the waist to achieve the width, resulting in a poor fit at the hip and crotch.

- The Rise Balance: For Jorts to sit correctly (often worn lower on the waist), the relationship between the Front Rise and Back Rise is critical. If the Back Rise is too short, the shorts will pull down when the wearer sits. If it’s too long, it creates excess “diaper” bunching.

- Leg Twist Control: Wide-leg patterns are more prone to Leg Twist (side seams skewing forward) after washing. We adjust the grainline on the pattern and utilize anti-twist cutting methods to ensure the side seams remain straight, even on 14oz rigid denim.

3. Handling Heavy Details: Carpenter Loops & Pockets

Most trending Jorts feature “workwear” elements: hammer loops, double-knee panels, and cargo pockets. These are high-risk areas for production defects.

- Reinforcement: A hammer loop that rips is a common return reason. We use Bar-tack machines (42-stitch cycle) at all stress points—pocket corners, belt loops, and tool loops.

- Pocket Stability: Large cargo pockets on baggy shorts can look sloppy if the fabric is too light. For these styles, we recommend a minimum weight of 11oz – 12.5oz. If a lighter summer fabric (10oz) is required, we apply fusible interlining inside the pocket flaps and openings to maintain structure.

4. Washing Large Surface Areas

Unlike slim shorts, baggy Jorts have large, flat panels of fabric. This exposes fabric defects and washing inconsistencies more easily.

- Stone Wash Consistency: On wide legs, stone washing must be carefully controlled to avoid “streaking” (uneven abrasion lines). We adjust the water-to-stone ratio and drum speed to ensure the abrasion is uniform across the wide thigh area.

- Hem Fraying: For the popular “cut-off” raw hem look, we apply a safety stitch (stay-stitch) 3mm–5mm above the raw edge. This allows the hem to fray naturally during the industrial wash but prevents the side seams from unravelling completely.

Conclusion: Ready for Scale?

Manufacturing baggy denim shorts requires a shift in mindset from “saving fabric” to “optimizing fabric.” It requires a factory that understands how pattern engineering affects the final FOB price.

If you are developing a Jorts collection and need a partner who can handle heavy-weight denim, complex cargo details, and high-volume cutting, send us your tech pack for a preliminary consumption calculation.

FAQ: Manufacturing Baggy Denim Shorts (Jorts)

Q1: What is the recommended minimum order quantity (MOQ) for custom Jorts?

- Our standard MOQ starts at 150-200 units per style/wash, which allows us to optimize fabric cutting (marker efficiency) and ensure stable chemical concentrations during the industrial washing process.

Q2: Can you develop custom “Carpenter” or “Cargo” details from a sketch?

- Yes. Our Tech & Pattern Making team can translate a hand sketch or a reference photo into a full CAD pattern. We specialize in engineering multi-pocket designs and reinforced hammer loops that are both functional and durable.

Q3: How do you manage shrinkage for 100% cotton (rigid) Jorts?

- Rigid denim can have a shrinkage rate of up to 8% – 10%. We wash a fabric lot sample before bulk cutting to determine the exact shrinkage factor. We then adjust the digital pattern to ensure the final measurements stay within the approved spec sheet.

Q4: Do you offer sustainable fabric options for the Jorts trend?

- Absolutely. We source a range of sustainable materials, including recycled cotton and organic cotton blends. These can be combined with our ozone washing or laser distressing techniques to reduce the environmental footprint of your collection.

Q5: Can you help us reduce the FOB price for wide-leg styles?

- The most effective way is through fabric width optimization. By reviewing your tech pack, we may suggest slight adjustments to the inseam or hem width (often by just 1cm) to improve the nesting in the marker, which can significantly reduce fabric consumption and cost.