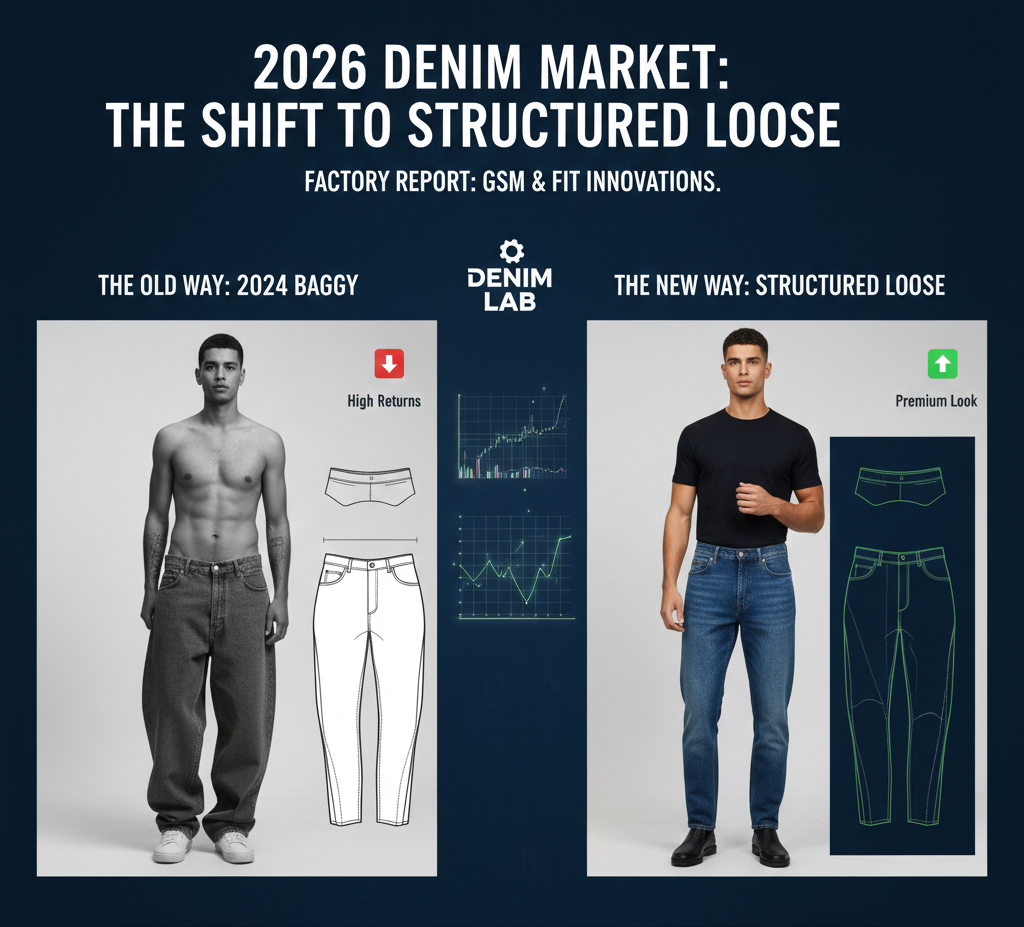

For professional denim buyers and brand founders, the question isn’t just about what is “in style,” but what is “in production.” As a custom denim manufacturing partner observing the shift in global tech packs for the 2026 season, we are seeing a distinct departure from the ultra-baggy silhouettes that dominated 2024.

The industry is currently navigating a pivot toward “Structured Loose.” This isn’t a return to the skinny era, but a refinement of volume. For a brand owner, understanding this transition is the difference between a high-selling core collection and a warehouse full of discounted inventory.

Why is the “Ultra-Baggy” Trend Evolving into “Structured Loose” for 2026?

In 2024, the market was flooded with “Big Boy” cuts—extremely wide legs with little to no tapering. While these served the peak of the streetwear cycle, our men’s jeans factory data shows they presented significant challenges for mass-market longevity. They are difficult to style for the average consumer and often result in high return rates due to “length drag” and “waist slippage.”

What we are seeing in 2026 is not the death of the loose fit, but its maturation. The trend is moving away from sloppy volume toward intentional volume. This transition is characterized by:

- A Defined Top Block: The waist and seat are becoming more fitted.

- Controlled Drape: The use of heavier, rigid fabrics to ensure the pant holds a shape.

- Functional Tapering: Subtle narrowing from the knee to the hem.

From a custom denim manufacturing perspective, this shift requires more precise pattern engineering than the oversized blocks of previous years.

The Foundation of Structure: 2026 Denim Fabric Trend Report

The “Structured Loose” look cannot be achieved with thin, lightweight fabrics. To get the architectural silhouette required for 2026, the fabric must have “body” and high GSM (Grams per Square Meter).

As a specialized men’s jeans factory, we have analyzed our current procurement and cutting-table data to provide this technical fabric report. These are the top 5 constructions driving the 2026 premium market.

📊 Factory Floor Data: Top 5 High-Demand Constructions

| Fabric Rank | Market Designation | Composition | Weight (GSM) | Primary 2026 Application |

| 01 | The “Architectural” Rigid | 100% Organic Cotton | 490 – 510 GSM | Structured Loose / Wide Leg |

| 02 | The “Heritage” Slub | 100% Ring-Spun Cotton | 440 – 460 GSM | Vintage Straight Fits |

| 03 | The “Dual-Core” Hybrid | 92% Co / 6% T400 / 2% Ly | 380 – 400 GSM | Premium Slim-Straight |

| 04 | The “Eco-Tough” Blend | 70% Cotton / 30% Hemp | 420 – 440 GSM | Sustainable Utility/Carpenter |

| 05 | The “Ozone-Ready” Grey | 80% Co / 20% Recycled Co | 460 – 480 GSM | Industrial Workwear |

Why These Specs Matter for Your Brand

When you move to 14oz+ rigid denim (Rank 01 & 05), shrinkage control becomes your biggest risk. In our custom denim manufacturing facility, we run three-stage wash tests on every fabric roll before the bulk cut. This ensures that the “Structured” look doesn’t become a “Distorted” look after the consumer’s first home wash.

What Technical Adjustments Define a “Structured Loose” Pattern?

It is easy to confuse these categories, but the technical blueprints used in a professional men’s jeans factory are quite different.

| Technical Feature | 2024 Baggy Fit | 2026 Structured Loose |

| Rise Measurement | Dropped / Low Rise | Mid to High Rise |

| Thigh Ease | +5cm to +7cm | +2.5cm to +3.5cm |

| Knee to Hem | Parallel (No Taper) | 1.5cm Subtle Taper |

| Fabric Selection | 11oz – 12oz | 13.5oz – 15oz Rigid |

The Structured Loose fit utilizes a higher rise to anchor the garment at the natural waist. This allows the volume of the leg to flow without the “saggy” aesthetic. For a private label denim brand, this makes the fit more accessible to a broader demographic—moving beyond Gen Z into the professional market.

How Does Pattern Engineering Reduce B2B Return Rates?

A common issue with oversized denim is “crotch sagging” and “back-yoke gaping.” In our custom denim manufacturing pattern room, we fix this through Anatomical Balancing.

Instead of just widening the side seams, we adjust the crotch curve to be deeper and more “U-shaped.” This allows the fabric to sit comfortably under the pelvis without excess bunching. Furthermore, we increase the yoke angle to ensure the waistband hugs the lower back, even when the wearer is seated.

Can Sustainable Washing Maintain the Integrity of Heavyweight Denim?

In 2026, the market demands sustainable denim production. As a leading men’s jeans factory, we implement Eco-Aging techniques that preserve the “structure” of the denim:

- Laser Whiskering: Replaces manual sandpapering to maintain fiber strength.

- Ozone Bleaching: Replaces chlorine, giving a “dry, vintage” look without damaging the fabric.

- Nano-bubble Softening: Uses 90% less water, ensuring 14oz fabric feels comfortable while maintaining its shape.

Why Should Brands Choose a Specialized Jeans Factory?

Many general apparel manufacturers lack the specialized machinery for custom denim manufacturing.

- Heavy-Duty Stitching: 14oz rigid denim requires specific needle gauges and thread tension.

- MOQ Flexibility: Because we are a specialized men’s jeans factory, we offer Low MOQ (200 pieces) programs to help brands test the market.

Summary: Navigating the 2026 Transition

The data from our cutting tables suggests the market is craving quality over quantity. The “Structured Loose” trend is a move toward garments that last longer, look better tailored, and command a higher retail price.

Our custom denim manufacturing team is available to help you refine your patterns. Contact our men’s jeans factory today to start your first sample.