This is not another generic “we make great jeans” article. As a factory that has focused on custom plus-size denim manufacturing for over 15 years, we have seen dozens of brands fail—not because their marketing was bad, but because they treated a Size 22W like a “scaled-up” Size 8.

When you are building a plus-size brand, you aren’t just selling a garment; you are selling confidence and a “no-gap” fit. For a B2B buyer or a startup founder, the challenge is finding a partner who understands the technical nuances of a 14W-26W pattern while offering the flexibility to test the market without massive inventory risk.

Here is the technical reality of how we engineer custom plus-size jeans that actually stay sold.

Why Do Plus-Size Denim Brands Suffer from a 30% Return Rate?

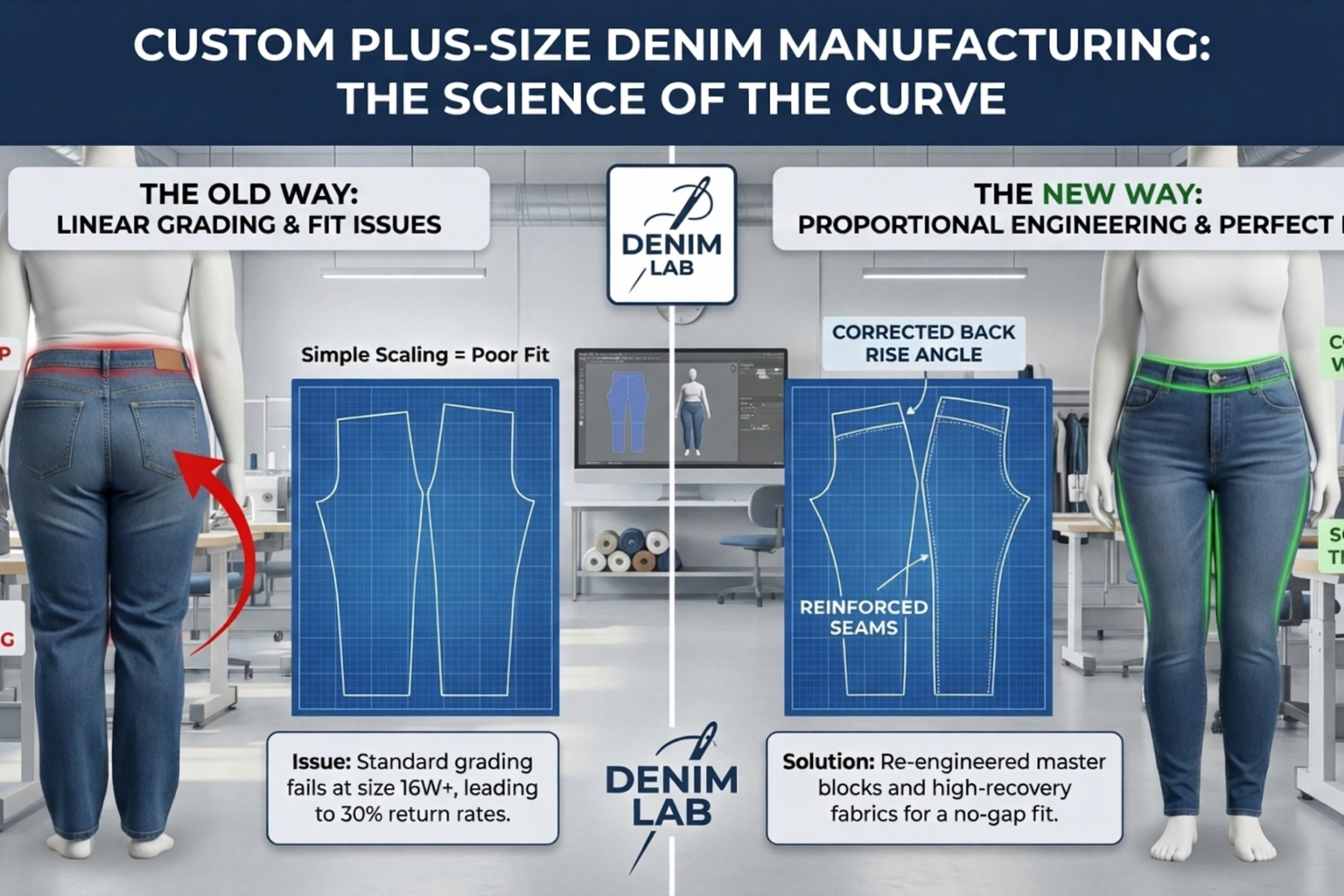

Most denim factories are built for “straight-size” production. Their efficiency comes from linear grading—adding a fixed amount of inches to the waist and hips as the size goes up. This works from size 2 to 10. It fails miserably at size 16W.

The result? Customers experience:

- The Waist Gap: Jeans that fit the hips but stand 2 inches away from the lower back.

- Thigh Blowouts: Fabric that shears or tears at the inner thigh due to improper seam tension.

- Knee Bagging: Fabric that loses its “memory” after two hours of wear, leaving the wearer with saggy knees.

In our facility, we don’t “grade up.” We re-engineer. We treat the 16W as a completely separate master block from the 8, ensuring the proportions reflect the reality of a curvy body.

How Can You Launch Custom Plus-Size Denim Without Huge MOQs?

The biggest barrier for emerging plus-size labels is the “1,000-piece minimum.” Large factories view custom plus-size as a specialty “headache” because it requires more fabric consumption per unit and more rigorous fit testing. They demand high MOQs to offset the development cost.

We’ve flipped that model. Because we have spent a decade building a specialized plus-size denim factory infrastructure, we offer a low MOQ of 200 pieces per style.

The “Pattern Library” Advantage

We don’t start your design from zero. Over the years, we have developed a “Pattern Library” of proven master blocks for various silhouettes: Skinny, Mom Fit, Baggy, and Wide Leg—all specifically for the 14W-26W range.

When you bring us a custom design, we adapt it to a foundation that has already been fit-tested on real bodies. This reduces development time and allows us to offer samples in 7-10 days.

Production Timelines Built for Speed

In the modern fashion cycle, “out of stock” means “lost revenue.” We have optimized our cutting and sewing lines to prioritize throughput without sacrificing the high-tension stitching required for plus-size denim.

| Order Quantity | Production Lead Time (After Sample Approval) |

| 200 – 1,000 pieces | 15 Days |

| 1,001 – 5,000 pieces | 20 Days |

| 5,001 – 10,000 pieces | 20 – 30 Days |

Note: These timelines are based on available fabric. Custom mill-run fabric adds approximately 10-15 days to the front end.

Why Is Linear Grading the “Silent Killer” of Plus-Size Jeans?

If your current plus-size jeans manufacturer tells you they can just “size up” your standard tech pack, you should expect high returns. Linear grading assumes that a body grows at the same rate everywhere. It doesn’t.

As sizes move into the 20W+ range, the seat (buttocks) and the upper thigh require a different geometric curve, not just more fabric.

Proportional Engineering: The Back Rise Angle

The most common fit issue is the “Waist Gap.” This happens because standard patterns don’t account for the tilt of the pelvis in plus-size bodies. We adjust the Back Rise Angle (the “Yoke” angle) to follow the inward curve of the lower back.

| Size Bracket | Typical Back Rise Angle Adjustment | Benefit to the Wearer |

| 14W – 18W | Baseline Master Block | Optimal starting point for curvy fits. |

| 20W – 24W | +4° Inward Tilt | Eliminates the gap at the back of the waistband. |

| 26W+ | +6° Inward Tilt | Ensures the jeans stay up without a belt. |

Pocket Placement and Visual Balance

Standard factories often use the same size back pocket for a size 14W as they do for a 24W. This makes the pockets look tiny and disproportionate, visually widening the wearer’s hips in an unflattering way.

As a specialist custom plus-size denim manufacturing partner, we increase the pocket dimensions and “pitch” (the angle of placement) for every two sizes. A size 22W gets a pocket that is roughly 20% larger than a size 14W, placed slightly closer to the center seam to create a slimming visual “lift.”

What Fabric Specs Are Mandatory for High-Performance Plus-Size Denim?

Plus-size denim is under significantly more “PSI” (pounds per square inch) than standard denim. When a customer sits down, the tension on the seat and knee seams increases by up to 40% more than in a size 6.

If you use “standard” stretch denim, the jeans will “bag out” by noon.

The Recovery Rate Requirement

Most denim brands look at “Stretch %,” but as a plus-size jeans manufacturer, we care about “Recovery Rate.” If a fabric stretches 40% but only recovers 70%, the jeans will be a full size larger after two hours of wear.

We recommend fabrics with the following technical specs for plus-size programs:

- Stretch: 35% – 45% (to allow for movement).

- Recovery: 92% or higher (to maintain the silhouette).

- Composition: We often suggest T400 or Lycra DualFX technology. These “dual-core” yarns provide the soft stretch of spandex but the “snap-back” power of polyester.

Opacity and “Grin-Through” Testing

Have you ever seen denim that looks semi-transparent or “white” at the thighs when stretched? This is called “Grin-through,” where the white elastic core shows through the indigo yarns.

In our lab, we perform an Opacity Stress Test. We stretch the fabric to 40% extension and check for yarn separation. For custom plus-size jeans, we generally recommend a minimum weight of 11.5 oz to 12.5 oz to ensure the fabric remains “beefy” and opaque even at maximum tension.

How Do We Fix Fit Issues Before the First Stitch is Sewn?

The “sample, ship, comment, repeat” cycle is slow and expensive. To achieve a 7-10 day sample turnaround, we use a 3-Phase validation process that relies on both data and human experience.

Phase 1: 3D Digital Avatar Simulation

Before cutting any fabric, we run your pattern through Optitex 3D simulation. We use digital avatars that represent a “Full Curvy” body type, not a “Standard Tall” model.

We look for “Heat Maps”—areas where the fabric tension is too high (indicated in red). If the crotch curve or the back rise shows high stress on the digital model, we adjust the pattern immediately.

Phase 2: The “Active Wear” Fit Test

A sample that looks good on a mannequin is useless. Our fit models (Sizes 16W, 20W, and 24W) perform an “Active Protocol”:

- The Squat Test: Does the waistband slip down?

- The Chair Test: Is there binding at the back of the knee?

- The 20-Minute Walk: Do the legs “spiral” or twist?

Phase 3: Industrial Stress Wash

Plus-size jeans are often washed more frequently by the end-user. We put every sample through 3 heavy industrial wash cycles to ensure the dimensional stability is locked in. We measure the shrinkage in all four directions to ensure your size 18W doesn’t arrive as a 16W.

Why Does Pocket and Hardware Engineering Change for Plus-Size?

In custom plus-size denim manufacturing, even the small details require a “solutions” mindset.

- Waistband Construction: For sizes 20W-26W, we often recommend a “Contoured Waistband.” Unlike a straight waistband (which is just a rectangle), a contoured waistband is cut on a curve. This allows it to wrap around the waist/hips without flipping over or digging in.

- Reinforced Crotch Seams: We use a higher Stitches Per Inch (SPI) count and specialized “felled seams” at the inner thigh. This prevents the “thigh-rub” friction from breaking the threads—the #1 cause of quality claims in plus-size denim.

- Hardware Placement: We use reinforced “tack buttons” and YKK locking zippers that can withstand the higher lateral pressure of a curvy fit.

Frequently Asked Questions from B2B Buyers

Can you help with custom branding and hardware for plus-size lines?

Yes. Even at our 200-piece MOQ, we offer full customization. This includes custom-engraved buttons, rivets, leather patches, and woven main labels. We can also develop custom wash formulas—from vintage stonewash to clean, dark resin rinses—specifically for your brand’s DNA.

What is your capacity for large-scale wholesale orders?

While we love supporting startups with 200-piece runs, we are an industrial-scale plus-size denim factory. Our monthly capacity exceeds 150,000 units. Whether you are ordering 200 pieces or 10,000 pieces, you get the same technical expertise and quality control.

How do you handle shipping and logistics for international brands?

We work with major 3PL providers to offer FOB, CIF, or DDP shipping. For most US and European clients, we manage the customs documentation to ensure a seamless “factory-to-warehouse” experience.

The Expertise You Can Trust: Real Results

We recently worked with a UK-based startup that was struggling with a 28% return rate on their 18W-24W range. Their previous factory was using standard grading.

By implementing our Proportional Engineering and switching to a high-recovery T400 fabric, we reduced their return rate to 7% within one season.

When you choose us as your plus-size jeans manufacturer, you aren’t just getting a supplier; you are getting an engineering team that understands the “Science of the Curve.”

Ready to build a plus-size denim line that fits perfectly every time? Our team is ready to review your tech packs. We offer custom plus-size denim manufacturing solutions that prioritize fit, speed, and low-risk growth.