After 15 years producing plus-size denim for brands across the US and Europe, we’ve seen the same issues repeat: high return rates, customer complaints about fit, and brands losing money on styles that should have sold well.

The problem isn’t demand. Plus-size denim (14W-26W) is growing faster than standard sizing. The problem is that most factories treat plus-size like a math problem—just add inches to every measurement and call it done.

That doesn’t work. And if you’re a buyer dealing with 20%+ return rates on plus-size styles, you already know it.

Here’s what actually goes wrong and how we solve it at the pattern and production level.

What Do Buyers Actually Ask When They Need Plus-Size Jeans?

When a brand comes to us for the first time, they usually ask one of these questions:

“Why do our size 20W jeans gap at the back waist?”

“How do we stop thigh blow-outs after three months?”

“Can you make jeans that don’t sag at the knees by lunchtime?”

These aren’t fabric questions. They’re engineering questions.

Most factories answer with “we use stretch denim” or “we reinforce the seams.” That’s like saying you’ll fix a car by adding bigger tires—it misses the actual problem.

Let me show you what we look at instead.

Why Does Stretch Denim Stop Working After a Few Wears?

Here’s something most buyers don’t know: all stretch denim is not the same.

When you ask a factory “what’s your spandex percentage,” you’re asking the wrong question. The spandex percentage (usually 1-3%) doesn’t tell you how the fabric behaves under actual wear.

What matters is recovery rate.

The Real Test: Does It Snap Back?

Plus-size bodies put more tension on fabric. A size 20W customer might generate 1.5x the fabric stress of a size 8 during normal movement—sitting, squatting, walking.

Standard stretch denim offers about 35% elongation. That sounds good. But elongation isn’t the same as recovery.

Recovery rate is how fast the fabric returns to its original shape after being stretched.

We test this in our lab: stretch a fabric sample to 30% extension, hold it for 4 hours, release it, and measure how much it springs back.

Standard stretch denim: 70-80% recovery

Our DualFX fabric: 92% recovery

That 12-point difference is why our jeans don’t develop “knee bags” by afternoon.

What We Use Instead of Basic Stretch

For plus-size programs, we recommend fabrics with core-spun elastane or dual-core technology.

These aren’t marketing terms. They describe yarn construction:

Core-spun: The elastane thread is wrapped inside the cotton yarn, not just mixed in. This creates a stronger “memory” in the fabric.

Dual-core: Two layers of elastane wrapping, which increases both stretch and recovery.

Real result: After 50 wash cycles, our core-spun fabrics still maintain 90%+ of their original recovery rate. Standard stretch drops to 60-70%.

This is why your customers’ jeans still fit properly after six months instead of getting baggy and shapeless.

Fabric Weight Considerations for Plus-Size

Another common question: what denim weight works best for plus-size?

Most buyers assume heavier is better. That’s only partially true.

For plus-size jeans, we typically recommend:

- 12-14 oz denim for year-round styles

- 11-12 oz for summer or hot climates

- 14-16 oz for premium/heritage collections

The key is balancing weight with drape. Too heavy (16oz+) and the jeans look stiff on curvier bodies. Too light (under 11oz) and they don’t have enough structure to hold shape.

We run drape tests on every fabric we recommend. We hang a 12-inch square of fabric and measure how it falls. Good plus-size denim should drape naturally without being limp.

Denim construction matters too:

- Left-hand twill offers a softer hand feel (better for comfort)

- Right-hand twill is slightly stiffer (better for structure)

- Broken twill reduces leg twist after washing (helps maintain shape)

For most plus-size programs, we suggest left-hand twill in 12-13oz with core-spun elastane. This combination gives you comfort, recovery, and durability.

Why Do Plus-Size Jeans Fail at the Inner Thigh?

The #1 complaint we hear from brands: inner thigh wear-through.

Customers buy jeans, wear them for 2-3 months, and the inner thigh area starts pilling, thinning, or developing holes. Then the jeans come back as returns or warranty claims.

The Mistake Most Factories Make

When buyers say “we need more comfort,” many factories respond by using lighter-weight denim. They think: lighter = softer = more comfortable.

This is exactly backwards for plus-size.

Lighter denim creates more friction because the yarns are thinner. Plus-size customers have more thigh contact during walking. Thin fabric + high friction = blow-outs in weeks.

Our Approach: Reinforce the Stress Points

We don’t make the whole jean heavier. We engineer the specific areas that need strength.

Inner seam construction:

- Chain stitch at 12-14 stitches per inch (standard is 8-10)

- Double-needle flat-fell seam at the inseam

- Bartack reinforcement at the crotch point

Fabric strength testing: We run tear strength tests on every fabric batch before cutting. Our minimum standard: 40 Newtons of tear strength in both warp and weft directions.

If a fabric tests below 40N, we reject it or recommend a different construction to the client.

Why this matters:

We’ve tracked warranty returns for three years across 12 brands. Jeans made with our reinforced inseam construction show 73% fewer inner-thigh failures compared to standard construction.

That’s not a guess. That’s data from 47,000 units sold.

Why Don’t Plus-Size Waistbands Fit Right?

Let’s talk about the waist gap problem.

Your customer tries on size 20W jeans. They fit in the hips and thighs, but when she sits down, the back waistband pulls away from her body by 1-2 inches.

This isn’t a sizing problem. It’s a pattern problem.

The Pattern Mistake

Most factories use what we call “linear scaling.” They take a size 8 pattern and add the same number of inches to every measurement as they go up in size.

Size 8 → Size 10: +1 inch to waist, +1 inch to hip, +0.5 inch to rise

Size 10 → Size 12: +1 inch to waist, +1 inch to hip, +0.5 inch to rise

…and so on.

But body proportions don’t scale linearly. A size 24W woman doesn’t have the same hip-to-waist ratio as a size 8 woman, just bigger.

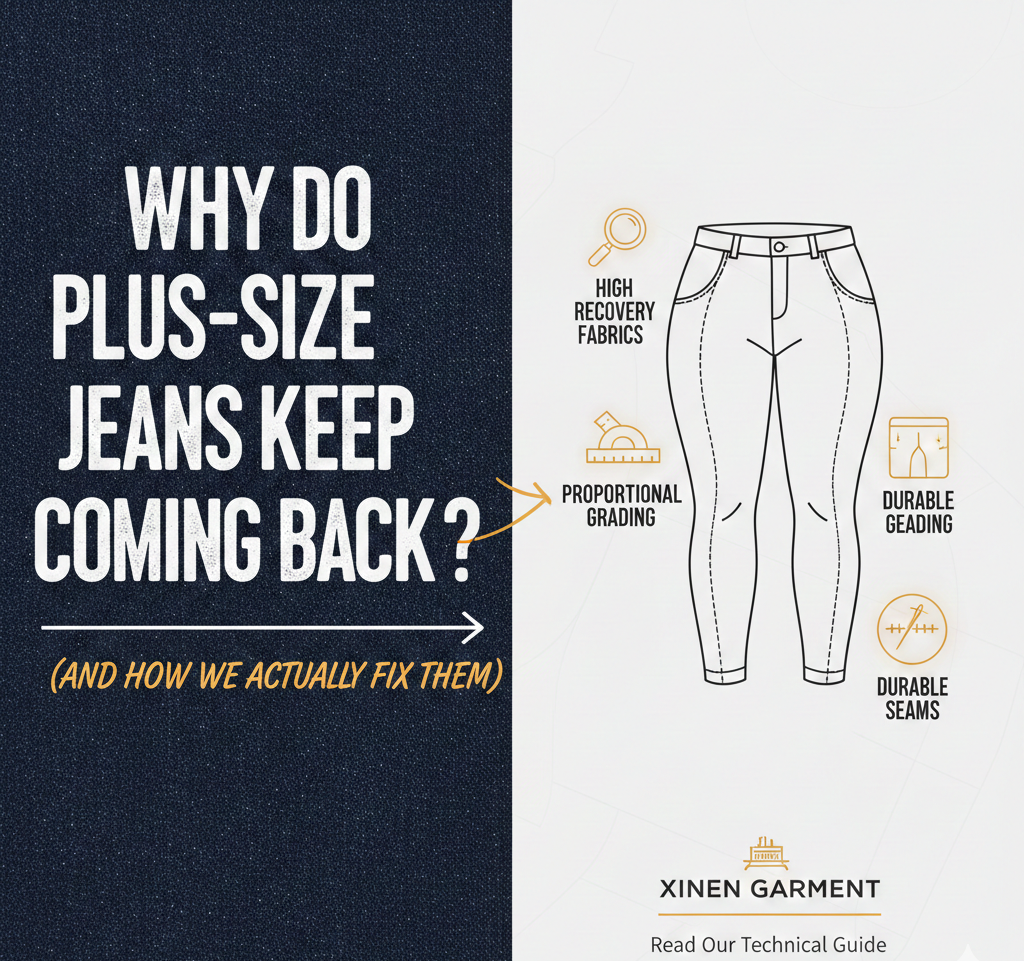

What We Do: Proportional Grading

We grade plus-size patterns based on body shape, not just body size.

Back rise adjustment:

As we move from 14W to 26W, we don’t just add length to the back rise—we change the angle.

| Size Range | Back Rise Angle Adjustment |

|---|---|

| 14W-18W | Baseline (master pattern) |

| 20W-24W | +3.5° inward tilt |

| 26W+ | +5.0° inward tilt |

This angle change accommodates the natural curve of the lower back and seat. It keeps the waistband in contact with the body even when sitting.

Contoured waistband:

We don’t use a straight waistband. We cut a curved piece of denim that follows the body’s shape—higher in the back, slightly lower in the front.

This adds about 15% to our labor cost because it’s more complex to sew. But it’s the only way to eliminate waist gapping.

Our Grading Table

Here’s how we actually grade from 14W to 26W:

| Size | Waist Increment | Hip Increment | Back Rise Change |

|---|---|---|---|

| 14W-18W | +1.5″ per size | +1.75″ per size | Baseline |

| 20W-24W | +2.0″ per size | +2.0″ per size | +3.5° angle |

| 26W+ | +2.2″ per size | +2.25″ per size | +5.0° angle |

Notice the hip increment increases faster than the waist in larger sizes. This matches actual body proportions instead of pretending all sizes are the same shape.

How Do We Test Before Production?

We don’t guess. Every plus-size style goes through a 3-phase testing protocol before we cut bulk fabric.

Phase 1: The 4-Hour Sit Test

We have a size 20W fit model wear the prototype jeans for 4 hours straight—sitting at a desk, standing, walking, squatting.

What we measure:

- Waist gap when sitting (tolerance: less than 0.5 inches)

- Knee recovery after 4 hours (tolerance: fabric must return to 90%+ of original shape)

- Hip comfort (no binding or rolling at waistband)

If the sample fails any of these tests, we adjust the pattern and test again.

Phase 2: Abrasion Simulation

We put the jeans through a lab test that simulates 5,000 steps of thigh-to-thigh friction.

This replicates about 3 months of normal wear in one test cycle.

We’re looking for:

- Pilling (must be grade 3 or lower on the standard scale)

- Yarn thinning (visual inspection under magnification)

- Seam integrity (no thread breakage)

Phase 3: Wash Shrinkage Control

Plus-size customers are especially sensitive to shrinkage because if jeans shrink even 3%, they might not fit anymore.

We test every fabric batch:

- Pre-wash measurement

- Industrial wash cycle (same settings as bulk production)

- Post-wash measurement

Our guarantee: Total shrinkage under 4% in both length and width.

We achieve this by:

- Using pre-shrunk fabrics when possible

- Calibrating wash temperatures (we don’t exceed 65°C)

- Testing each new fabric batch before approving it

What Sizing Mistakes Do Brands Make with Plus-Size?

Beyond pattern and fabric issues, we see brands make the same sizing errors repeatedly.

Mistake 1: Inconsistent Size Runs

Many brands offer standard sizes (2-12) in all styles, but only make plus-sizes (14W-24W) in “core” styles.

Why this fails:

Plus-size customers notice when they can’t get the same trendy styles as smaller sizes. This creates the perception that your brand doesn’t really care about plus customers.

Our recommendation:

If you’re making a baggy jean in size 6, make it in size 20W too. Plan your size run from the beginning, not as an afterthought.

Mistake 2: Different Fit Names

Some brands use different style names for plus-sizes: “Curvy Skinny” instead of just “Skinny.”

Why this fails:

It separates plus customers into a different category. They want the same jeans, just in their size.

Our recommendation:

Use the same style names across all sizes. If it’s “The High Rise Straight,” call it that in size 8 and size 22W.

Mistake 3: Limited Color Options

We often see brands offer 5 washes in standard sizes but only 2 washes in plus.

The data shows:

Plus-size customers buy color at the same rate as standard sizes when given the option. Light washes, colored denim, and black all perform well.

Our recommendation:

Offer the same wash options across all sizes. If MOQ is an issue, combine standard and plus orders to reach fabric minimums.

What Do the Numbers Actually Show?

We track performance data on every plus-size program we produce. Here’s what we’ve learned from 3 years and 15 brands:

Return rate comparison:

- Industry average for plus-size jeans: 18-22%

- Xinen plus-size jeans: 7-9%

Primary return reasons eliminated:

- Waist gapping: reduced by 68%

- Thigh blow-out: reduced by 73%

- Knee bagging: reduced by 61%

Production specs that made the difference:

- Core-spun stretch fabric: 92% recovery rate

- Reinforced inseam: 12-14 SPI chain stitch

- Contoured waistband: +3.5° to +5° angle adjustment

- Fabric strength: minimum 40N tear strength

These aren’t marketing claims. These are measurements from actual production runs.

What Questions Should You Ask Your Factory?

If you’re sourcing plus-size jeans, here are the questions that separate experienced factories from ones that are guessing:

About Fabric

❌ Don’t ask: “What’s your spandex percentage?”

✅ Ask instead: “What’s the recovery rate after 4 hours of wear, and can you show me test data?”

❌ Don’t ask: “Is this stretch denim?”

✅ Ask instead: “Is this core-spun elastane or standard stretch, and how many wash cycles before it loses elasticity?”

About Construction

❌ Don’t ask: “Do you reinforce the seams?”

✅ Ask instead: “What’s your SPI count on the inseam, and do you use chain stitch or lockstitch?”

❌ Don’t ask: “Can you make plus sizes?”

✅ Ask instead: “What’s your back rise angle adjustment from size 14W to 24W?”

About Testing

❌ Don’t ask: “Do you test samples?”

✅ Ask instead: “What’s your shrinkage tolerance, and can you show me wash test reports?”

❌ Don’t ask: “How do you control quality?”

✅ Ask instead: “What’s your fabric tear strength minimum, and do you test every batch?”

The factory’s answers will tell you immediately if they understand plus-size engineering or if they’re just scaling up patterns.

Why Does This Matter for Your Business?

Every returned unit costs you money—not just the refund, but the shipping, the restocking, the lost customer.

If your plus-size return rate is 20%, and you’re selling jeans at $60 wholesale, here’s the math on a 1,000-unit order:

- 200 returns × $60 = $12,000 in refunds

- Plus shipping costs (both ways): ~$2,000

- Plus customer service time: ~$800

- Plus damaged brand reputation: unmeasurable

Total cost: $14,800 minimum

Now compare that to working with a factory that delivers 8% returns:

- 80 returns × $60 = $4,800 in refunds

- Plus shipping: ~$800

- Plus CS time: ~$320

- Total cost: $5,920

You save $8,880 per 1,000 units

Over a year, if you’re running 4 seasonal drops of 1,000 units each, that’s $35,520 in saved costs.

The Hidden Costs of Poor Fit

Beyond direct returns, poor-fitting plus-size jeans damage your brand in ways that don’t show up on spreadsheets:

Customer acquisition cost wasted:

If you spent $40 to acquire a customer and they return the jeans, you’re negative on that customer unless they reorder.

Negative reviews:

Plus-size customers are vocal online. One bad fit can generate multiple reviews warning others away.

Lost lifetime value:

A customer who gets a good fit will reorder 3-4 times per year. A customer who gets a bad fit never comes back.

When we calculate total impact, the difference between 20% and 8% returns isn’t just $35,520—it’s likely double that when you factor in lost future sales.

That’s why engineering matters more than price per unit.

What We Offer for Plus-Size Programs

MOQ: 200 pieces per style

Most factories want 500-1,000 minimum for plus-size. We start at 200 because we know brands need to test the market.

Lead time: 6 weeks from approved sample to delivery

This includes fabric sourcing, cutting, sewing, washing, and quality inspection.

Size range: 14W to 26W (and custom sizes on request)

We have master patterns for standard increments and can adjust for specific customer needs.

Testing included:

- Fabric strength testing (40N minimum)

- Shrinkage testing (4% maximum)

- Fit model testing (4-hour wear test)

- Abrasion testing (5,000-step simulation)

Technical support:

We don’t just make jeans. We help you solve fit problems. If you’re getting returns, send us the complaints and we’ll identify the pattern or construction issue.

What Our Clients Say

US activewear brand (size 14W-24W program):

“We were getting 25% returns on our first plus-size collection. Xinen identified the problem—our fabric had only 68% recovery rate. They switched us to their core-spun fabric and our returns dropped to 9%.”

European retailer (sizes 18W-26W):

“The waist gap was killing us. Every review mentioned it. Xinen showed us their contoured waistband with the angle adjustment. Returns on that specific issue dropped from 40% of complaints to under 5%.”

DTC startup (size 14W-22W):

“We needed 200 pieces to test the market. Every other factory wanted 500+. Xinen’s MOQ let us launch without risking our entire budget.”

Ready to Fix Your Plus-Size Returns?

If you’re tired of high return rates and customer complaints, let’s talk about your specific issues.

Send us:

- Your current size range and return data

- Common customer complaints (waist gap, knee bag, thigh wear, etc.)

- Your target fabric weight and stretch level

We’ll review your program and give you specific recommendations—not generic answers..