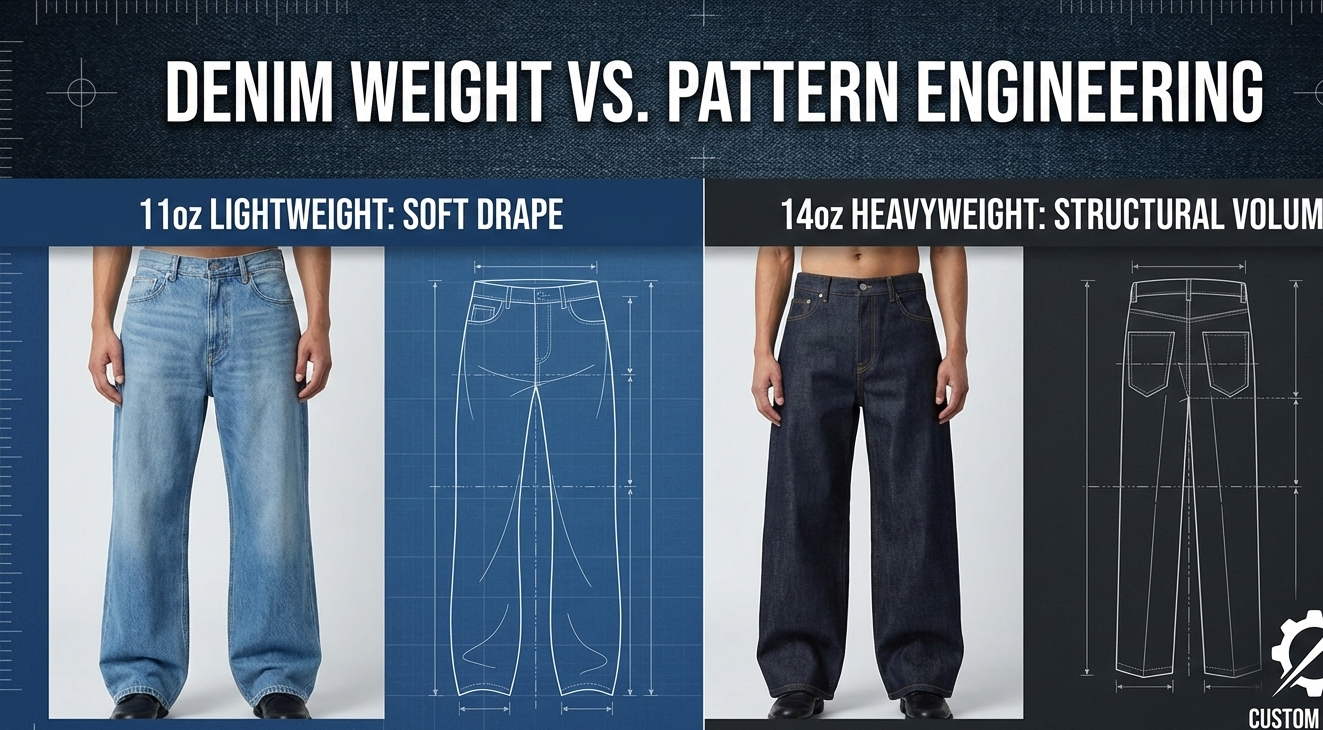

Last month, a client from California sent us their wide-leg jean tech pack with a quick note: “We want to move from an 11oz summer denim to a 14oz heritage weight for our next drop. Let’s keep the pattern exactly the same to save time on sampling, okay?”

My answer was a polite but firm no.

As a custom denim manufacturing partner for over 12 years, I’ve seen this mistake more than any other. On a slim or straight-cut jean, the difference between 11oz and 14oz is noticeable, but the garment usually stays wearable. On a wide-leg jean, however, fabric weight fundamentally changes the physics of the fit.

If you don’t re-engineer the pattern when you increase the fabric weight, you end up with “costume-like” volume, stiff crotches, and return rates that can sink a collection. Here is a look at why GSM (Grams per Square Meter) dictates your pattern geometry.

Why Does Fabric Weight Matter More on Wide-Leg Silhouettes?

In the world of men’s jeans factory production, we talk a lot about “surface area.” A standard slim jean might use 1.8 meters of fabric. A wide-leg jean uses 2.5 meters or more. When you have that much extra denim hanging off the body, gravity and fabric rigidity become your primary design challenges.

The 11oz Behavior: The “Collapse”

Lightweight denim (10-11oz) is soft. It doesn’t have enough internal structure to stand away from the body. In a wide-leg cut, this fabric tends to drape inward, clinging to the thighs and collapsing around the calves. To make 11oz denim actually look “wide,” you ironically have to make the pattern wider to compensate for that collapse.

The 14oz Behavior: The “Architecture”

Heavyweight denim (14-15oz) has “memory.” It is architectural. It wants to maintain its own shape rather than following the shape of the leg. When you put a 14oz fabric into a wide-leg pattern, it stands away from the skin, creating an air gap between the wearer and the cloth. This creates a very structured, premium look, but it also means the fabric doesn’t “forgive” pattern mistakes.

How Do You Adjust Measurements for Different Weights?

When moving from a lightweight 11oz to a heavy 14oz denim, the most counter-intuitive thing we do is reduce the width of the leg. Many designers think that a heavier fabric needs more room. The opposite is true. Because 14oz denim stands out on its own, it creates “visual volume.” If you keep the same wide measurements from your 11oz pattern, the 14oz version will look twice as big on the person, often looking like the jeans are wearing the customer instead of the other way around.

To illustrate this, I’ve pulled a standard spec comparison from our denim factory floor. This shows how we adjust a Size 32 master pattern when a client switches weights.

📏 Technical Spec Comparison: 11oz vs. 14oz Wide-Leg Engineering

Baseline: Men’s Size 32 (Finished Measurements)

| Pattern Point | 11oz Lightweight | 14oz Heavyweight | Adjustment | Technical Reason |

| Thigh (Flat) | 35.5 cm | 33.5 cm | – 2.0 cm | 14oz stands away from the skin; less width creates the same “look.” |

| Knee (Flat) | 28.5 cm | 27.0 cm | – 1.5 cm | Prevents a “bulky tube” look in heavy fabric. |

| Leg Opening | 24.5 cm | 23.5 cm | – 1.0 cm | Heavy fabric holds its own hem; a smaller opening looks cleaner. |

| Front Rise | 29.5 cm | 30.5 cm | + 1.0 cm | Rigid fabric resists bending; extra height prevents “pulling.” |

| Back Rise | 40.5 cm | 42.0 cm | + 1.5 cm | Prevents the waistband from gapping when sitting in stiff denim. |

| Crotch Depth | 27.5 cm | 28.5 cm | + 1.0 cm | Deeper “U-curve” allows movement in non-stretch 14oz. |

Why Does Heavier Denim Require a Different Rise and Crotch Curve?

If you’ve ever worn a pair of heavy, raw denim jeans and felt like you couldn’t sit down comfortably, the problem wasn’t the fabric—it was the crotch curve.

In custom denim manufacturing, we use two different curve shapes: the V-curve and the U-curve.

- 11oz Denim: We can use a sharper, shallower curve because the fabric is thin enough to bunch up and move out of the way when you sit.

- 14oz Denim: The fabric is too thick to bunch up comfortably. If the curve is too shallow, the fabric will “bite” or pinch.

We re-engineer 14oz wide-leg patterns with a deeper, rounded U-shaped crotch. This creates a “pocket” for the body to sit in, ensuring that the heavy fabric doesn’t create a stiff shelf in the front. We also add roughly 1cm to 1.5cm to the Back Rise. Since heavy denim doesn’t stretch or drape over the glutes, that extra vertical room is the only thing preventing the waistband from pulling down every time the wearer moves.

How Does Shrinkage Compensation Vary by Weight?

One of the biggest risks in a men’s jeans factory is assuming shrinkage is a flat percentage. It isn’t.

Heavier denim usually uses thicker, more tightly twisted yarns. When these yarns hit the industrial wash, they have more “potential energy” to contract.

- 11oz Denim typically shrinks 2-3% in length.

- 14oz Denim can shrink anywhere from 5% to 7% depending on the mill.

If we are aiming for a finished 32-inch inseam, we might cut the 11oz pattern at 33 inches. For the 14oz version, we often have to cut at 34.5 inches. If you don’t adjust this at the cutting stage, you’ll end up with a “high-water” jean that is too short for the market. We perform 3-stage wash tests on every new fabric weight specifically to avoid this sizing disaster.

What Construction Details Change with Higher GSM?

Pattern shape isn’t the only thing that needs to evolve. The way we physically put the jeans together changes when we move into “heavyweight” territory.

Thread Weight and Tension

In our custom denim manufacturing facility, we switch thread weights based on fabric GSM. For 11oz denim, we use standard Tex 40 thread. For 14oz+, we move to Tex 60 or 80. If you use thin thread on heavy denim, the seams will look “sunken” and cheap. Heavier thread gives that bold, high-end “workwear” stitch look that brands want in 2026.

Stitch Density (SPI)

It sounds counter-intuitive, but we actually reduce the number of stitches per inch (SPI) for 14oz denim.

- 11oz: 9-10 stitches per inch.

- 14oz: 7-8 stitches per inch.If you put too many needle holes in a heavy, rigid fabric, you essentially “perforate” the seam, making it more likely to tear. Fewer, stronger stitches are the hallmark of a professionally manufactured heavy jean.

Choosing the Right Weight for Your Brand Positioning

As a brand owner, you need to decide if the “premium” feel of 14oz is worth the technical hurdles.

- The 11oz Market: Great for summer drops, budget-friendly lines, and customers who prioritize comfort and “softness” from day one. These are easier to manufacture and have lower shipping costs.

- The 14oz Market: Essential for premium, heritage, or “structured” streetwear brands. These command a higher retail price because of the hand-feel and the architectural silhouette. However, they require much more precise pattern engineering to get right.

Summary: Don’t Skip the Engineering Phase

The temptation to “just swap the fabric” is strong when you’re facing tight production deadlines. But in my experience, the time you save by skipping pattern adjustment is usually spent six months later dealing with customer service emails and warehouse returns.

A wide-leg jean is a 3D structure. When you change the weight of the material, you change the stability of that structure. By adjusting the leg width, deepening the crotch curve, and recalculating shrinkage, we ensure that the “14oz version” of your best-selling jean actually fits better than the original.

Would you like a technical review of your tech pack?

If you’re moving to a different fabric weight for your 2026 collection, our men’s jeans factory team can help you recalibrate your specs. Contact us today to discuss your project and see how our custom denim manufacturing expertise can lower your return rates.