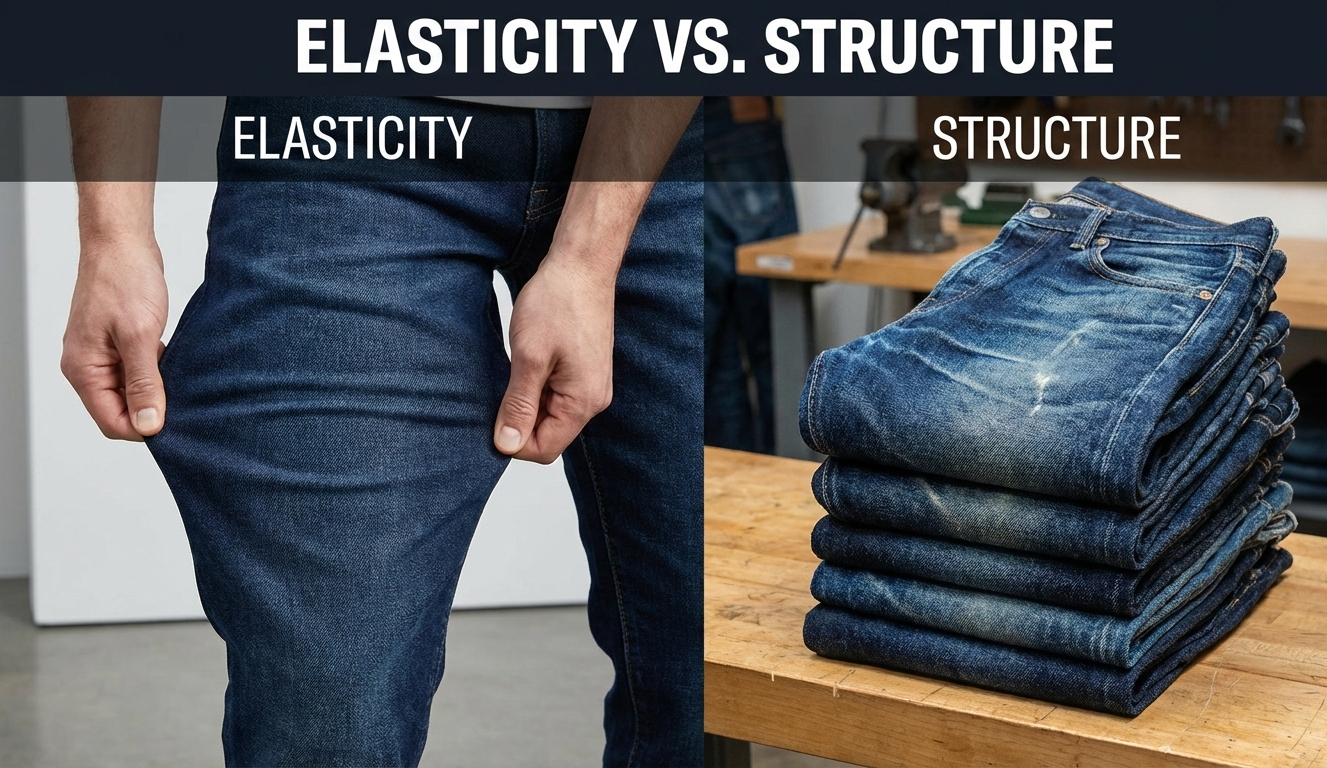

In the denim world, the choice between stretch and non-stretch (rigid) fabric is often treated as a simple style preference. A brand might say, “We want a vintage look,” or “We want a skinny fit.”

However, from where we stand on the factory floor, this decision is fundamentally an engineering one. It is the single most critical variable in the entire manufacturing process. It dictates the pattern geometry, the sewing thread tension, the shrinkage calculation during washing, and ultimately, your return rates.

We have seen tech packs for rigid jeans that were cut like leggings (impossible to wear), and stretch jeans that were cut like vintage workwear (baggy and unflattering).

As a custom denim manufacturing partner, our goal is to help you understand the physics behind these fabrics. This guide explores the technical trade-offs between stretch and rigid denim, helping you make the right decision for your brand’s longevity and product quality.

What Is Stretch Denim from a Production Perspective?

To a customer, stretch denim is just “soft jeans.” To a manufacturer, it is a complex composite material that behaves like a living thing.

Stretch denim is cotton woven with an elastomer, typically elastane (Spandex/Lycra) or polyester blends. While the percentage of elastane might seem small—usually between 1% and 4%—it completely alters the mechanical properties of the fabric.

The Factor of “Growth” and “Recovery”

In production, we don’t just look at how much a fabric stretches; we look at its recovery.

- Stretch is how far the fabric extends under tension.

- Recovery is its ability to snap back to its original shape.

Low-quality stretch denim extends but doesn’t recover. This leads to the dreaded “knee bagging” or a waistband that gaps after three hours of wear. High-quality stretch denim (often called “power stretch” or using T400 fibers) has high recovery.

Manufacturing Implications

When we cut stretch denim, the fabric must be “relaxed.” If we pull the fabric tight while spreading it on the cutting table, it will snap back after cutting, resulting in panels that are smaller than the pattern. We have to rest the fabric rolls for 24 to 48 hours before cutting to ensure the tension is neutralized. This is a hidden time cost in production that brands rarely see.

What Is Non-Stretch (Rigid) Denim?

Non-stretch, or rigid denim, is the foundation of jeans history. It is typically 100% cotton, though sometimes it includes other natural fibers like hemp or linen.

From a manufacturing standpoint, rigid denim is “honest.” It has zero give. It is dimensionally stable after the initial shrinkage is removed. This stability creates the sharp, architectural lines associated with high-end heritage brands.

However, rigid denim is unforgiving.

In a stretch jean, if the pattern is 1cm too tight at the hip, the fabric expands to accommodate the body. In a rigid jean, if the pattern is 1cm too tight, the customer cannot button the pants. Precision in pattern grading becomes non-negotiable with rigid fabrics.

How Does Fabric Choice Change Pattern Engineering?

This is the most common mistake we fix for new clients: attempting to use the same pattern for both stretch and rigid fabrics.

The Concept of “Negative Ease” vs. “Positive Ease”

- Stretch Denim (Negative Ease): For a skinny or slim stretch jean, we often engineer the pattern to be smaller than the actual body measurements. We rely on the fabric’s elasticity to stretch over the body. A pattern for a 30-inch waist might actually measure 29 inches on the table, stretching to fit a 30-31 inch waist.

- Rigid Denim (Positive Ease): Rigid denim requires “wearing ease.” We must build extra room into the pattern for movement—sitting, squatting, and walking. A size 30 rigid jean must measure at least 30.5 or 31 inches, plus additional room in the seat and thigh.

If you switch a style from stretch to rigid without re-engineering the pattern, the garment will likely fail fitting tests.

Curvature and Waistbands

On stretch denim, we can use a curved waistband that molds to the hips. On rigid denim, we often cut waistbands on the “straight grain” to prevent them from stretching out over time. The geometry of the yoke and the rise angle also changes. Rigid denim needs a deeper “saddle” (crotch curve) to allow for comfortable sitting, whereas stretch denim can hug the under-buttock area more closely.

Which Fabric Handles “Heavy Washing” Better?

The wash house is where the personality of the jean is created, but it is also where the fabric is put under maximum stress.

The Limits of Elastane

Elastane is sensitive to heat and chemicals. High temperatures (used in industrial dryers) and strong bleaching agents (like chlorine or heavy permanganate sprays) can make elastic fibers brittle.

If you push stretch denim too hard in the wash process, you get “ripple effects” or “bacon waistbands,” where the elastane snaps and the cotton fabric puckers.

This limits the types of vintage washes you can achieve with stretch denim. While technology is improving, achieving a true, high-contrast 1990s “stone wash” is technically difficult with high-stretch fabrics without compromising the lifespan of the garment.

The Beauty of Rigid Abrasion

Rigid denim is the king of the wash house. Because cotton is robust, we can subject it to heavy stone washing, aggressive sanding, and laser burning without destroying the structural integrity of the weave.

Rigid denim develops clearer, higher-contrast “whiskers” (fading lines at the hip) and “honeycombs” (fading behind the knees). The abrasion looks natural because it physically wears down the cotton yarn. On stretch denim, abrasion can sometimes look flat or fuzzy because the synthetic fibers don’t fade the same way cotton does.

Is Comfort the Only Reason to Choose Stretch?

It is easy to assume that Stretch = Comfort and Rigid = Discomfort. But that is an oversimplification.

The “Sausage Casing” Effect

Cheap stretch denim can sometimes feel less comfortable because it traps heat. Elastane and polyester are synthetic; they don’t breathe as well as cotton. In hot climates, a tight stretch jean can feel sticky and restrictive.

The Break-In Period

Rigid denim is notoriously stiff when brand new. This is a hurdle for customer acquisition. A customer trying on raw rigid denim for the first time might feel restricted.

However, once broken in, rigid denim molds to the wearer’s body shape in a way stretch never does. It becomes “custom fit” over months of wear.

For brands targeting true denim enthusiasts, this break-in journey is a selling point. For brands targeting mass-market commercial consumers, the initial stiffness of rigid denim usually leads to higher return rates.

Durability: Which One Lasts Longer?

This is a nuanced topic.

Stretch Denim Failure Points:

- Bagging Out: Over time, the elastic fibers lose their memory. The knees stay baggy even after washing.

- Thigh Rub: In high-friction areas (like the inner thighs), the cotton can wear away, leaving only the translucent elastic strings. This leads to holes appearing faster than in rigid denim.

Rigid Denim Failure Points:

- Crotch Blowout: Because the fabric doesn’t stretch, stress accumulates at the seams. If a wearer squats, the tension goes directly to the weakest point—usually the crotch seam—causing it to rip.

- Seam Abrasion: The folded edges of hems and pockets wear down faster because they are stiff and rub against surfaces.

Generally, a heavy-weight rigid jean (13oz+) will outlive a stretch jean by years, provided the sizing allows for movement.

How Should Brands Choose? (The Decision Matrix)

When we consult with brands on denim fabric sourcing, we guide them through a decision matrix based on their specific market positioning.

Scenario A: The Lifestyle & Commercial Brand

- Target: Office workers, moms, mass-market retail.

- Priority: Consistent fit, immediate comfort, low return rates.

- Recommendation: Comfort Stretch (1-2% Elastane).This offers the look of authentic denim but provides enough tolerance in sizing to fit various body shapes. It reduces returns because the fit is more forgiving.

Scenario B: The Heritage & Streetwear Brand

- Target: Sneakerheads, vintage lovers, fashion-forward youth.

- Priority: Authentic wash effects, silhouette structure, durability.

- Recommendation: 100% Cotton Rigid.To achieve the wide-leg, stacked, or carpentry looks that are trending, you need the structure of rigid denim. Stretch denim collapses and drapes too much for these architectural silhouettes.

Scenario C: The “Body Shaping” Brand

- Target: Customers looking for lifting and sculpting.

- Priority: Holding shape, smoothing silhouette.

- Recommendation: High-Performance Stretch (T400 / Bi-stretch).Here, you need technical fabrics with high recovery. The fabric cost is higher, but it performs a specific function that rigid denim cannot.

Visual Comparison: Stretch vs. Rigid at a Glance

| Feature | Stretch Denim | Rigid (Non-Stretch) Denim |

| Primary Material | Cotton + Elastane/Poly | 100% Cotton (mostly) |

| Sizing Tolerance | High (Forgiving fit) | Low (Must be precise) |

| Pattern Ease | Negative Ease (Smaller than body) | Positive Ease (Larger than body) |

| Wash Potential | Sensitive to heat/bleach | Can handle heavy abrasion |

| Silhouette | Best for Skinny, Slim, Tapered | Best for Straight, Wide, Loose |

| Aging | Softens, may lose shape | Molds to body, holds shape |

| Production Risk | Shrinkage & Growth management | Grading accuracy |

Can You Have Both in One Collection?

Absolutely. In fact, most successful modern brands do.

A balanced collection might look like this:

- Core Skinny/Slim Fits: 11oz – 12oz Stretch Denim.

- Trendy Wide-Leg/Dad Fits: 13oz Rigid Denim.

- Summer Shorts: 10oz Rigid or Comfort Stretch.

The key is communicating this to the customer. If a customer is size 28 in your stretch skinny jeans, they might be size 29 or 30 in your rigid wide-leg jeans. Your size chart and product descriptions must reflect this difference to avoid confusion.

Final Thoughts: The Factory’s Role in Your Decision

There is no “better” denim, only the right denim for the specific garment you are building.

The mistake many brands make is picking a fabric based solely on a swatch sent by a mill, without considering how that fabric will behave on the sewing line or in the laundry.

At our factory, we encourage fabric testing before bulk production. We make “shrinkage blankets” to test how the fabric reacts to washing. We sew “mock-up legs” to see if the seam puckers.

We believe that custom denim manufacturing is about partnership. We don’t just take your order; we validate your engineering.

If you are unsure whether your next collection should be rigid or stretch, or if you are struggling with fit consistency across different fabrics, let’s have a conversation. We can analyze your tech packs and recommend the best fabric sourcing strategy to match your brand’s vision.

Ready to develop your next denim range?

Contact our technical team today to discuss your fabric requirements and pattern engineering needs.