A Real-World Fit & Manufacturing Guide for B2B Buyers

If you read enough threads on Reddit or Quora about starting a denim brand, one pattern shows up again and again:

“We thought basic jeans would be easy. They weren’t.”

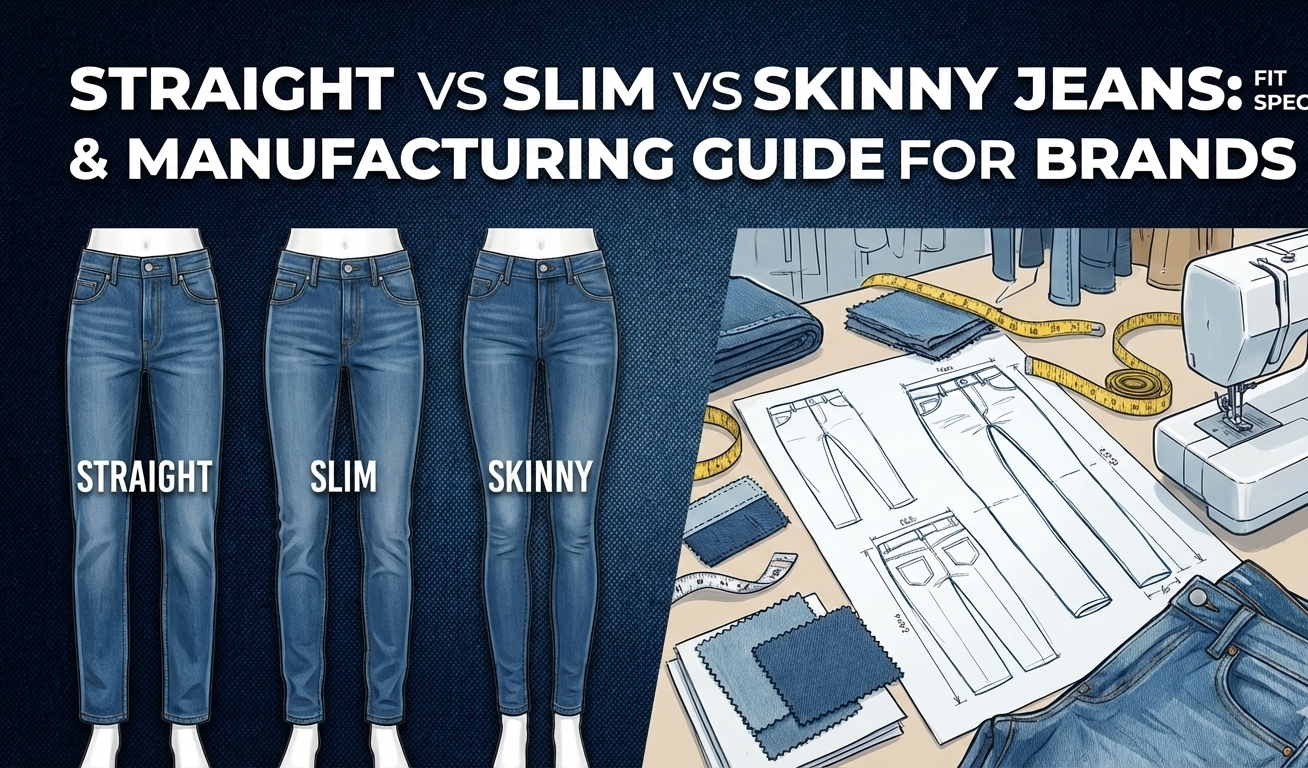

Straight, slim, and skinny jeans look simple. In reality, they are some of the most unforgiving styles to develop and produce, especially for smaller or newer brands.

1. “Classic Fits” Are Where Most Brands Make Their First Mistake

Many buyers assume:

- Trend styles = complicated

- Classic styles = safe

In manufacturing, it’s often the opposite.

Oversized or loose fits hide small errors.

Straight, slim, and skinny fits do not.

On Reddit, brand owners often complain about:

- Jeans that look fine on a hanger but fit wrong on body

- “Almost correct” samples that never feel quite right

- Bulk orders fitting differently from samples

Most of these problems come down to fit definition and measurement control, not factory capability.

2. Straight, Slim, Skinny: How Factories Actually See Them

Straight Fit

From a factory’s point of view, straight fit means:

- Thigh, knee, and leg opening are closely related

- Very little taper below the knee

Common issue:

If knee or leg opening is even 1–1.5 cm off, the jeans either look too baggy or unintentionally slim.

This is why straight fits often require more revisions than people expect.

Slim Fit

Slim fit sits in the most confusing middle ground.

Factories usually interpret slim as:

- Narrower thigh than straight

- Slight taper from knee to hem

Common issue:

Without clear specs, one factory’s “slim” becomes another factory’s “straight with stretch.”

Many Quora questions around slim jeans are basically asking:

“Why do my slim jeans fit differently every time?”

Answer: unclear measurements + fabric mismatch.

Skinny Fit

Skinny jeans are less about measurements and more about fabric behavior.

Factories focus on:

- Stretch percentage

- Recovery after wash and wear

Common issue:

Buyers approve a sample that feels okay, but bulk production feels tighter or loses shape after washing.

This is usually a fabric and wash control issue, not sewing.

3. Fit Names Don’t Matter — Measurement Sheets Do

One of the most repeated answers on Quora from experienced manufacturers is simple:

“Don’t tell us the fit name. Show us the numbers.”

For classic jeans, your spec sheet should clearly define:

- Waist

- Hip

- Thigh

- Knee

- Leg opening

- Front rise / back rise

You should also confirm:

- Measurement method (flat or circumference)

- Units (cm or inches)

- Tolerance range

Without this, even a good factory will guess — and guessing leads to mistakes.

4. Fabric Choice Changes Fit More Than Most Buyers Expect

A common Reddit complaint:

“We kept the same measurements, but the fit still changed.”

This usually happens when:

- Fabric composition changes

- Stretch percentage is different

- Wash process is adjusted

Examples:

- 100% cotton works well for straight fits but is risky for slim or skinny

- Stretch denim makes slim/skinny wearable but exaggerates measurement errors

Real-world rule:

You can’t finalize fit before fabric. They must be developed together.

5. Why “Basic” Jeans Have Higher Error Rates

This sounds counterintuitive, but it’s true.

Classic jeans:

- Have less design distraction

- Rely completely on proportion and comfort

- Are judged more strictly by customers

When something feels wrong, customers notice immediately.

That’s why many experienced factories say:

“Basic styles need the most experience.”

6. A Practical Development Process That Actually Works

Based on common advice shared by manufacturers and buyers online:

- Lock your fit reference first

- Build a detailed measurement sheet

- Develop fabric and wash with that fit

- Approve a pre-production sample

- Freeze specs for repeat orders

Trying to adjust fit during bulk production almost always ends badly.

7. How to Communicate Better With Denim Suppliers

Instead of asking:

- “Can you make slim jeans?”

Ask:

- “Here is our target thigh, knee, and leg opening. Can you match this consistently?”

Good factories prefer clear specs over vague fit names.

Final Thought

If you’re a smaller or younger brand focusing on classic denim:

- Straight, slim, and skinny jeans are not entry-level products

- They require precision, patience, and documentation

Get the fit right once, and it becomes your brand’s foundation.

Get it wrong, and you’ll keep chasing corrections.