As a factory manager who has spent over 15 years on the production floor, I’ve seen the “mass exodus” of the garment industry to Southeast Asia. I get it—on paper, the labor is cheaper. If you are making basic t-shirts or simple tote bags, China might not be your first choice anymore.

But denim is a different beast. It is a product of chemistry, engineering, and a lot of manual skill. When brands come back to us after trying cheaper regions, they usually say the same thing: “The samples were fine, but the bulk production was a mess.”

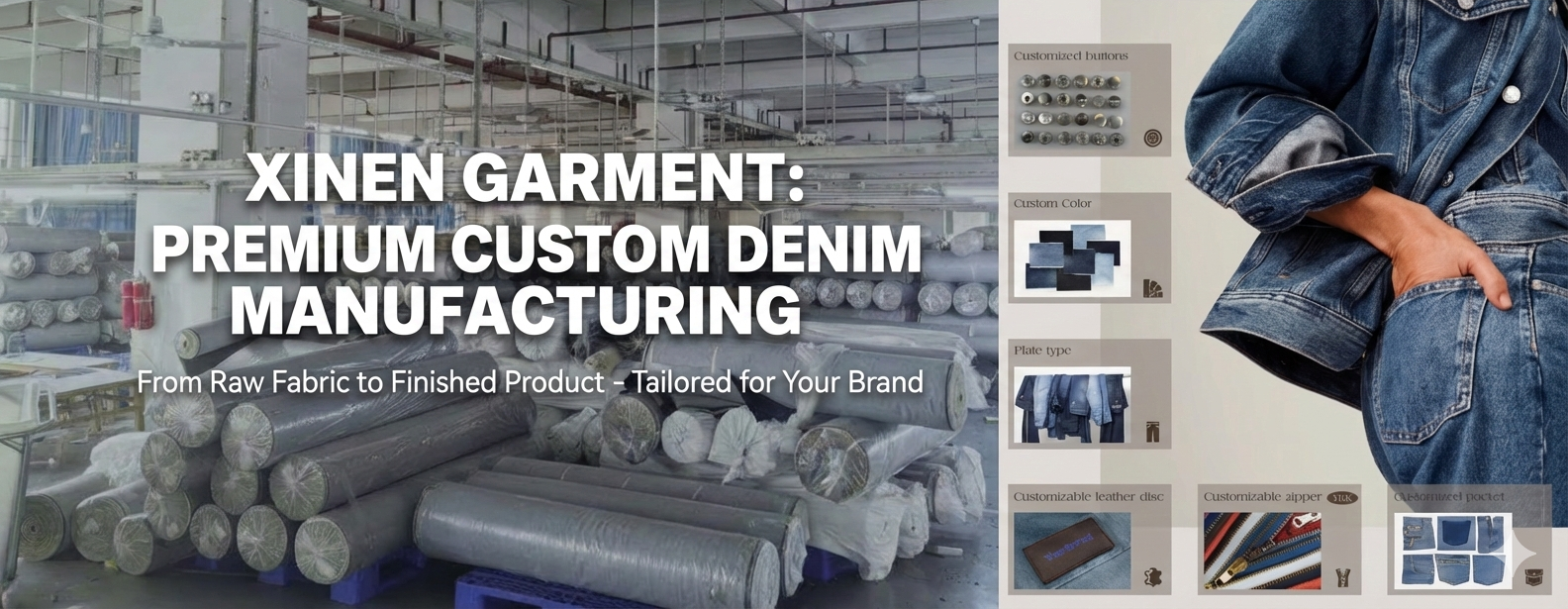

Here is my honest take on why the Chinese supply chain still wins for premium denim.

Is the “50-Mile” Supply Chain Really That Important?

In our industry, time is money. In China’s denim hubs, everything we need—from 14oz raw denim and YKK zippers to specialized copper rivets—is literally within an hour’s drive.

If you produce in a region that lacks this infrastructure, your factory is constantly waiting. They wait for imported fabric to clear customs; they wait for buttons to arrive from overseas. A small change in your design can delay production by weeks. Here, we can pivot in days. That speed-to-market is what keeps your inventory fresh.

Can Newer Manufacturing Hubs Handle Complex Denim Washing?

You can sew a pair of jeans anywhere, but the “soul” of the jean is created in the wash house. This is where most production goes wrong. Consistent washing requires two things: expensive machinery (like Laser and Ozone systems) and a technician who has seen it all.

Our wash masters understand how a 98% cotton / 2% spandex blend reacts to enzyme heat compared to a 100% rigid cotton. They know how to get that perfect “vintage fade” without eating through the pocket bags. Most emerging regions simply haven’t had the 30 years of trial-and-error that we have had here in China.

Are You Paying for Cheap Labor or Experienced Hands?

There is a big difference between a “sewing operator” and a “denim specialist.” Sewing heavy-weight denim requires handling industrial machines that can punch through four layers of thick fabric at the waistband or the felled seams.

An experienced operator in my factory knows how to maintain even tension so the legs don’t twist after the first wash. In cheaper regions, you might save 50 cents on labor per pair, but you often pay for it later in high defect rates and customer returns. In premium denim, experience is the best insurance policy for your brand.

Why is Scaling from 300 to 30,000 Units Harder Than It Looks?

Many massive factories in other countries only want the “easy” orders—50,000 pieces of one style. They aren’t set up for the modern brand that needs to test the market with 300 or 500 pieces first.

We have spent years optimizing our lines to be flexible. We can handle a small, high-detail “drop” for a boutique label just as easily as a large wholesale run for a global retailer. We grow with our clients. We don’t mind starting small, because we have the capacity to scale up the moment your style goes viral.

The Factory Manager’s Bottom Line

If you only care about the absolute lowest FOB price, I’ll be the first to tell you: China is not the cheapest.

But if you care about your jeans fitting the same in every size, your washes looking consistent in every batch, and your samples arriving on time, then the Chinese denim ecosystem is still your best partner. You aren’t just paying for a pair of pants; you’re paying for a stable business.