When brands start a new denim project, one of the first questions I get asked is: “What weight should we use?” Most people jump straight to the 14oz because they want that “authentic” feel. But in the factory, we know that weight changes everything—from how the needle moves to how much you’ll pay for shipping.

If you are stuck between 12oz and 14oz, you need to look past the number and understand how the fabric actually lives in production and on the customer.

What Does the “Oz” Actually Mean for Your Production?

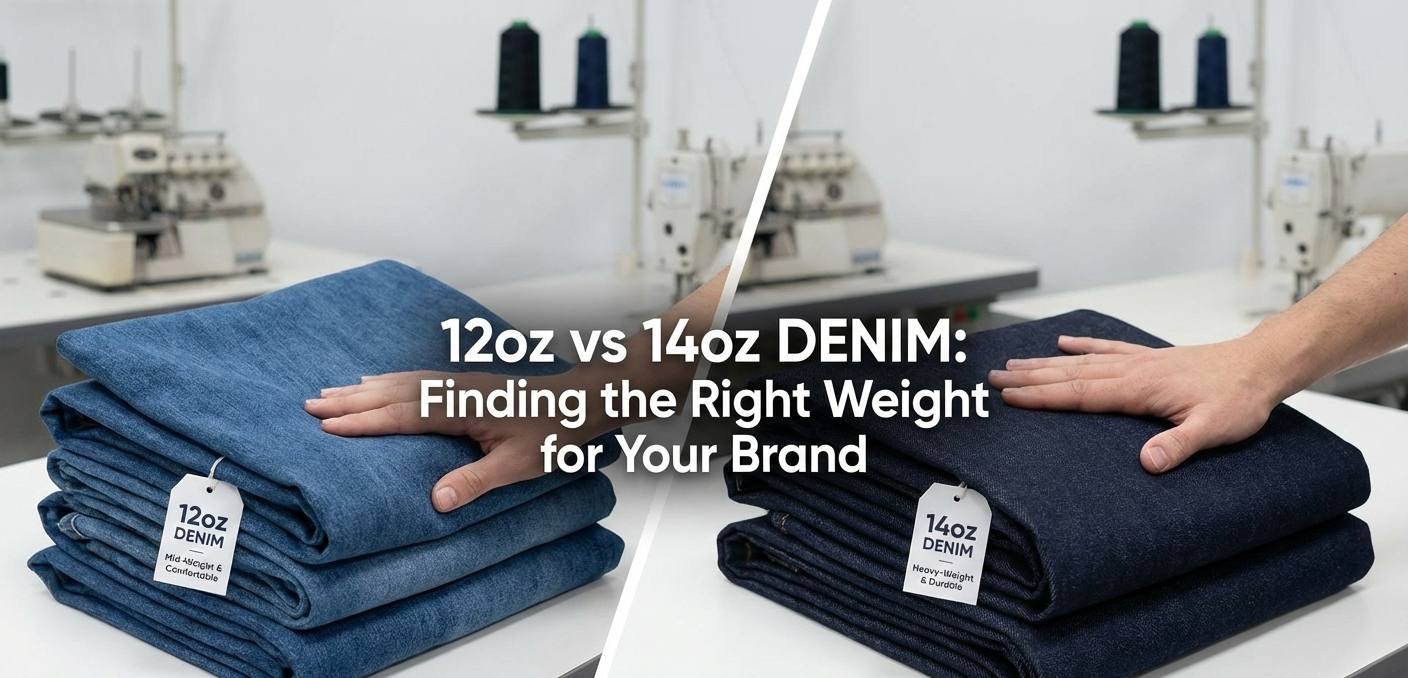

In simple terms, the “oz” refers to the weight of one square yard of fabric. But for us in the workshop, it represents density. A 12oz denim is considered “mid-weight,” while 14oz is the start of “heavy-weight.”

It’s not just about being thicker; it’s about how the yarn is twisted and how tightly it’s woven. A 14oz fabric has more “body.” It’s stiffer and harder to fold. A 12oz fabric has more “drape.” It follows the body’s movement much more easily.

Why is 12oz Denim the “Safe” Bet for Most Brands?

If you are building a collection for a general audience—people who want to buy jeans and wear them comfortably the same day—12oz is usually the sweet spot.

- Comfort: It doesn’t require a “break-in” period. It feels relatively soft right off the rack.

- Versatility: It works for slim fits, straight legs, and even women’s denim styles. It’s also breathable enough for year-round wear.

- Manufacturing: It’s easier to sew. We have fewer broken needles and less “bulk” at the seams (like the crotch or waistband). This usually means a smoother production run and lower labor costs.

When Should You Opt for the Heavy-Duty 14oz?

14oz is for the brands that want that “vintage” or “heritage” look. If your target customer is a denim enthusiast who loves high-contrast fades and raw denim, 12oz will feel too “flimsy” to them.

- Structure: If you are designing “Baggy Jorts” or wide-leg carpenter pants, 14oz holds the shape. It won’t collapse or look “saggy” like lighter fabrics might.

- Durability: This is workwear-grade material. It resists abrasion much better.

- The Look: When we do industrial washing (like stone washing), 14oz denim develops much deeper textures. You get those beautiful “honeycombs” behind the knees and sharp whiskers at the hips that light denim just can’t replicate.

Does Fabric Weight Really Affect Your Final Costs?

Yes, and often in ways brands don’t expect. This is the “factory reality” part:

- Shipping Costs: If you order 1,000 pairs of 14oz jeans, that shipment is literally 15% heavier than a 12oz order. If you are shipping by air, that is a massive hit to your margin.

- Labor & Energy: 14oz denim is harder on the machines. It takes longer to dry in our industrial dryers, which uses more energy.

- Wastage: Heavy denim is less “forgiving” during cutting. If the pattern isn’t perfect, the stiff fabric will show every mistake.

How Do You Decide Based on Your Customer?

Ask yourself: “Where is my customer wearing these?”

- The Urban Professional: If they are wearing jeans to the office or for a casual night out, go with 12oz. They want comfort and mobility.

- The Heritage/Workwear Fan: If they are wearing these with boots and want a pair that lasts five years, go with 14oz. They expect the stiffness; it’s a sign of quality to them.

My Honest Advice as a Manufacturer

Don’t choose 14oz just because you think it sounds more “premium.” A poorly made 14oz jean is just an uncomfortable piece of clothing.

In my experience, 12oz is the most “commercial” weight—it has the lowest return rate because the fit is more predictable. Save the 14oz for your limited edition “Premium” or “Vintage” lines where the customer knows exactly what they are signing up for.

Next Step for Your Brand: Not sure how the weights feel in person? We can send you swatches of both 12oz and 14oz in various washes so you can feel the “hand-feel” for yourself before we start sampling.

FAQ: Common Questions About Denim Weights

Q1: Will the same pattern work for both 12oz and 14oz fabrics?

- Not exactly. 14oz denim is much stiffer and has less “give” or drape compared to 12oz.

- Heavy denim is less forgiving during cutting and sewing.

- Because of the density, a 14oz jean will often feel tighter in the waist and hips if you use a pattern designed for 12oz fabric. We usually recommend a small pattern adjustment for the heavier material to ensure the fit remains consistent.

Q2: Does the fabric weight affect the final FOB price?

- Yes. 14oz denim is more expensive to produce because it requires more energy to dry during the washing process and is harder on our sewing machines.

- You also have to consider shipping costs; an order of 1,000 pairs of 14oz jeans is approximately 15% heavier than a 12oz order.

- If you are shipping by air, these weight differences will significantly impact your final margins.

Q3: Is 14oz denim too hot for summer collections?

- Generally, yes. 12oz is considered a versatile, mid-weight fabric that is breathable enough for year-round wear.

- 14oz is a dense, heavy-duty material.

- While some “denim-heads” wear heavy raw denim all year, the average customer will find 14oz too heavy and stiff for high-summer temperatures.

Q4: Which weight produces better “distressed” looks?

- If you want sharp “whiskers” and deep “honeycomb” fades, 14oz is the winner.

- Industrial stone washing creates much deeper textures on heavier denim.

- 12oz denim can still be distressed, but the effects will look softer and more subtle because the fabric is more flexible.