In the current streetwear landscape, the silhouette is getting wider, and the branding is getting louder. Baggy fit jeans provide a massive canvas for logos—spanning across the crotch, wrapping around the leg, or covering the entire back panel.

However, denim is one of the most difficult fabrics to print on. It is textured, thick, and most importantly, unstable. The indigo dye used in jeans loves to “migrate” (bleed) into your ink, turning your crisp white logo into a dull blue mess.

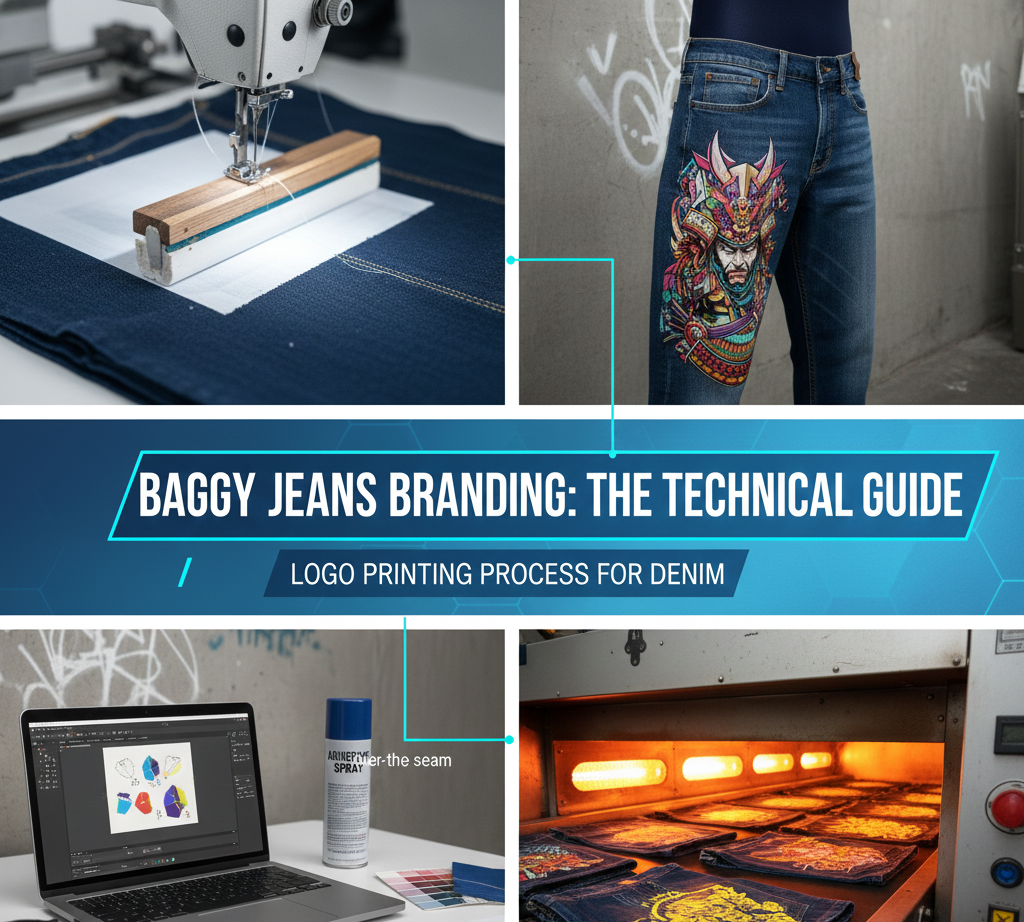

Here is the technical workflow for executing high-quality logo prints on baggy denim, from design file to the curing oven.

1.The Design Phase: Vector & Placement

Printing on denim is not like printing on a t-shirt. The texture of the twill weave will break up fine lines.

- Minimum Line Weight: Avoid lines thinner than 2 points. The “peaks and valleys” of the denim surface will swallow fine details.

- The “Baggy” Canvas: The trend in baggy jeans is “Over-the-Seam” printing.

- Challenge: The side seam is a literal bump (often 3-4 layers of fabric thick).

- Solution: If you want a print to wrap around the leg, you must design it to accept a “break” or gap at the seam, OR you must print on the panels (cut pieces) before the jeans are sewn together.

2.Choosing the Method: Ink Technologies

Not all inks stick to denim. Standard water-based inks often look washed out on dark indigo. You need high-opacity solutions.

A. Discharge Printing (The “Bleach” Effect)

This is the gold standard for dark denim. Instead of putting ink on the fabric, discharge ink removes the indigo dye from the cotton, reverting it to its natural off-white color.

- Pros: Zero “hand feel” (soft to touch), vintage look, no cracking.

- Cons: Unpredictable results depending on the fabric batch; smells strong during production.

B. Silicone Ink (The Premium Choice)

Used by high-end brands (like Fear of God or Off-White).

- Pros: extremely stretchy (won’t crack), high-gloss or matte finish, feels rubbery and premium.

- Cons: Very expensive, requires catalyst mixing, long curing times.

C. DTF (Direct to Film) Transfers

The modern solution for complex, multi-color graphics. The design is printed on a film and heat-pressed onto the jeans.

- Pros: Can handle photo-realistic images, cheaper for small batches (MOQ).

- Cons: Can feel like a “sticker” if the design is too large; less durable than screen printing.

3.The Production Process: Step-by-Step

Step 1: The “Panel” vs. “Garment” Decision

- Panel Printing (Best for Quality): The factory cuts the fabric into leg shapes, sends the flat fabric to the printer, and then sews the jeans. This allows for perfect edge-to-edge printing without seam bumps.

- Finished Garment Printing (Best for Speed): The jeans are fully sewn, then placed on the pallet. This is harder for baggy jeans because the excess fabric is heavy and can drag the print out of alignment.

Step 2: The Base & The Blocker

If using Plastisol ink (standard screen print), you cannot just print White on Blue.

- Flash: Pre-heat the fabric.

- Grey Blocker: Print a layer of grey carbon-based ink. This acts as a wall to stop the indigo dye from rising.

- Flash: Semi-cure the blocker.

- Top Color: Print your white or colored logo on top of the blocker.

Step 3: Curing (The Danger Zone)

Denim is thick and holds moisture. If the ink isn’t cured at the right temperature (usually 320°F / 160°C) all the way through, the print will crack after one wash.

- Tip: Because baggy jeans are heavy, the conveyor belt speed on the dryer must be slowed down to ensure heat penetrates the thick fabric.

4.Comparison Matrix: Which Method for Your Brand?

| Feature | Discharge Printing | High-Density (Puff) Plastisol | DTF Transfer |

| Best For | Vintage, distressed, “integrated” looks. | 3D logos, Y2K aesthetics, bold branding. | Multi-color anime graphics or photos. |

| Hand Feel | Soft (No feel). | Hard / Textured / Rubber-like. | Plastic / Sticker feel. |

| Durability | ⭐⭐⭐⭐⭐ (Permanent) | ⭐⭐⭐ (Can crack if stretched) | ⭐⭐⭐ (Fades after 50 washes) |

| Cost | $$(Medium) | $$ (Medium) | $ (Low for small qty) |

| Seam Friendly? | Yes | No (Will break at seams) | Yes (If applied correctly) |

Printing on baggy jeans is an engineering challenge as much as a design choice. The success of the product depends on managing indigo migration and handling the heavy weight of the garment.

For the most premium streetwear look, opt for Panel Printing using Silicone or Discharge inks. It requires better planning (printing before sewing), but the result is a seamless, retail-ready product that justifies a higher price point.