Why Sourcing Denim from China is a Strategic Choice for Emerging Brands

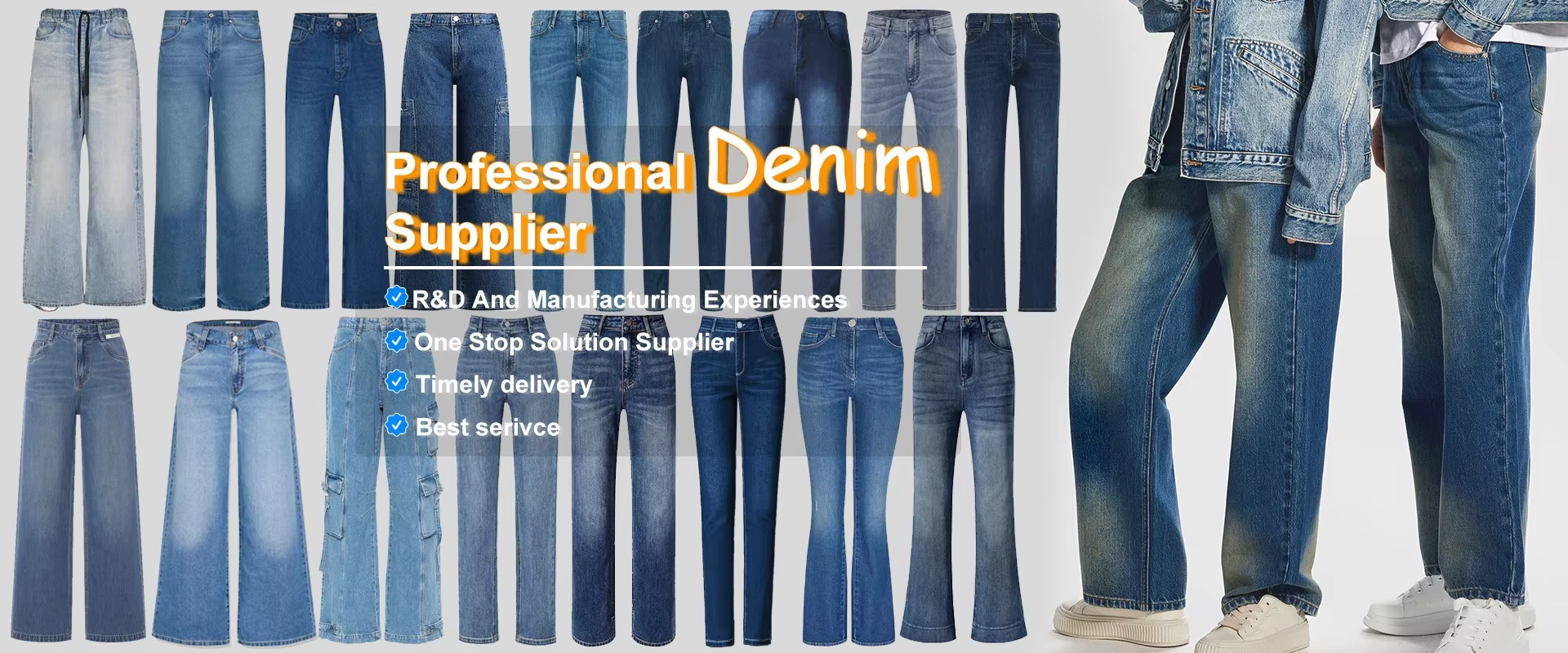

In the fast-paced world of fashion, bringing a new denim brand to life requires more than just great design—it demands a reliable, high-quality, and cost-effective manufacturing partner. For decades, China has been the undisputed leader in textile and garment manufacturing, and for good reason. As a professional jeans manufacturer in China, we’ve seen firsthand how our expertise, advanced technology, and integrated supply chain can be the catalyst for an emerging brand’s success.

This guide will take you through the essential steps of sourcing denim apparel from China, from understanding the market to building a long-term partnership. Whether you’re a startup or an established brand looking to expand your denim collection, we’ll show you why a strategic partnership with a Chinese manufacturer is the ultimate game-changer.

Chapter 1: The China Advantage: Unpacking the Value Proposition

When you choose to source your denim from China, you’re not just buying a product; you’re gaining access to a comprehensive ecosystem of manufacturing excellence.

- Manufacturing Prowess & Scale: China’s manufacturing infrastructure is unmatched. Factories are equipped with the latest machinery for everything from automated cutting and stitching to specialized laser-finishing and ozone washing. This allows for both small-batch prototyping and large-scale bulk production with consistent quality.

- Integrated Supply Chain: From raw cotton to finished jeans, China’s textile supply chain is fully integrated. This means we have direct access to high-quality denim fabrics (including organic cotton and recycled blends), trims, buttons, zippers, and all the components needed to create a premium product. This integration reduces lead times and minimizes sourcing complexities for our clients.

- Skilled Labor & Expertise: Generations of experience in garment production have created a highly skilled workforce. Our artisans and technicians are experts in intricate denim processes—from durable double-stitching to unique distress techniques and complex embroidery. This craftsmanship is what sets high-quality denim apart.

- Competitive Pricing: While quality is our priority, the economies of scale and efficient processes in China allow us to offer highly competitive pricing without compromising on material or craftsmanship. This is crucial for new brands looking to manage costs and maximize their margins.

Chapter 2: Navigating the Sourcing Process: A Step-by-Step Guide

As a partner in your brand’s journey, we recommend the following process for a seamless and successful collaboration.

Step 1: Define Your Vision & Specifications Before reaching out, have a clear vision of your product. This includes:

- Design & Technical Packs: Provide detailed sketches, measurements, and technical specifications (Tech Packs) for each style.

- Fabric & Wash Preferences: Specify the type of denim you want (e.g., rigid, stretch, selvedge), its weight (oz/sq yd), and the desired wash/finish (e.g., raw, light wash, acid wash).

- Trims & Details: Document all hardware (buttons, rivets), labels, patches, and stitching details.

Step 2: Vetting Potential Manufacturers Finding the right partner is critical. Look for a manufacturer that can demonstrate:

- Experience & Specialization: Do they specialize in jeans? Ask for their portfolio of work.

- Quality Control (QC): How do they ensure quality at every stage of production, from fabric inspection to final garment check?

- Certifications: Are they certified for ethical labor (e.g., BSCI, SEDEX) and sustainable practices (e.g., GOTS, OEKO-TEX)?

- Communication: A responsive and English-speaking team is essential for smooth project management.

Step 3: Sample & Prototyping Once you select a manufacturer, the first step is creating a prototype. We work closely with our clients to produce a physical sample that meets all their specifications. This is a crucial phase for making adjustments and approving the design before moving to bulk production.

Step 4: Bulk Production & Quality Assurance Upon sample approval, we move to production. Our robust quality control system ensures that every pair of jeans meets your standards. We conduct inspections at various stages:

- Pre-Production Check: Inspecting all raw materials before cutting.

- In-Line Inspection: Checking garments during stitching.

- Final Random Inspection (FRI): A comprehensive check of finished products before packing.

Chapter 3: Our Commitment to Quality and Sustainability

At Guangxi Xinen Garment, we don’t just manufacture jeans; we craft them with precision and a commitment to responsible production.

- Precision and Durability: We use high-quality, durable materials and employ advanced techniques to ensure every pair of jeans is built to last. Our focus on detailed craftsmanship means clean stitching, perfectly aligned seams, and robust hardware.

- Ethical Manufacturing: We are committed to ethical labor practices and a safe working environment for our employees. Our factory is regularly audited to ensure we meet or exceed international standards.

- Sustainable Practices: We are constantly investing in eco-friendly technologies. Our sustainable solutions include water-saving denim washing techniques, use of recycled fabrics, and reduced chemical usage. This helps our brand partners meet the growing demand for sustainable fashion.

Conclusion: Partner with a Chinese Jeans Manufacturer for Success

Launching a denim collection is a monumental task, but with the right manufacturing partner, it can be a rewarding journey. By choosing a professional, high-quality jeans manufacturer in China, you gain a partner dedicated to your success, offering unparalleled expertise, efficiency, and a commitment to quality.

Ready to bring your denim brand to life? We invite you to explore our professional collections and learn more about how we can help you with your bulk order needs.